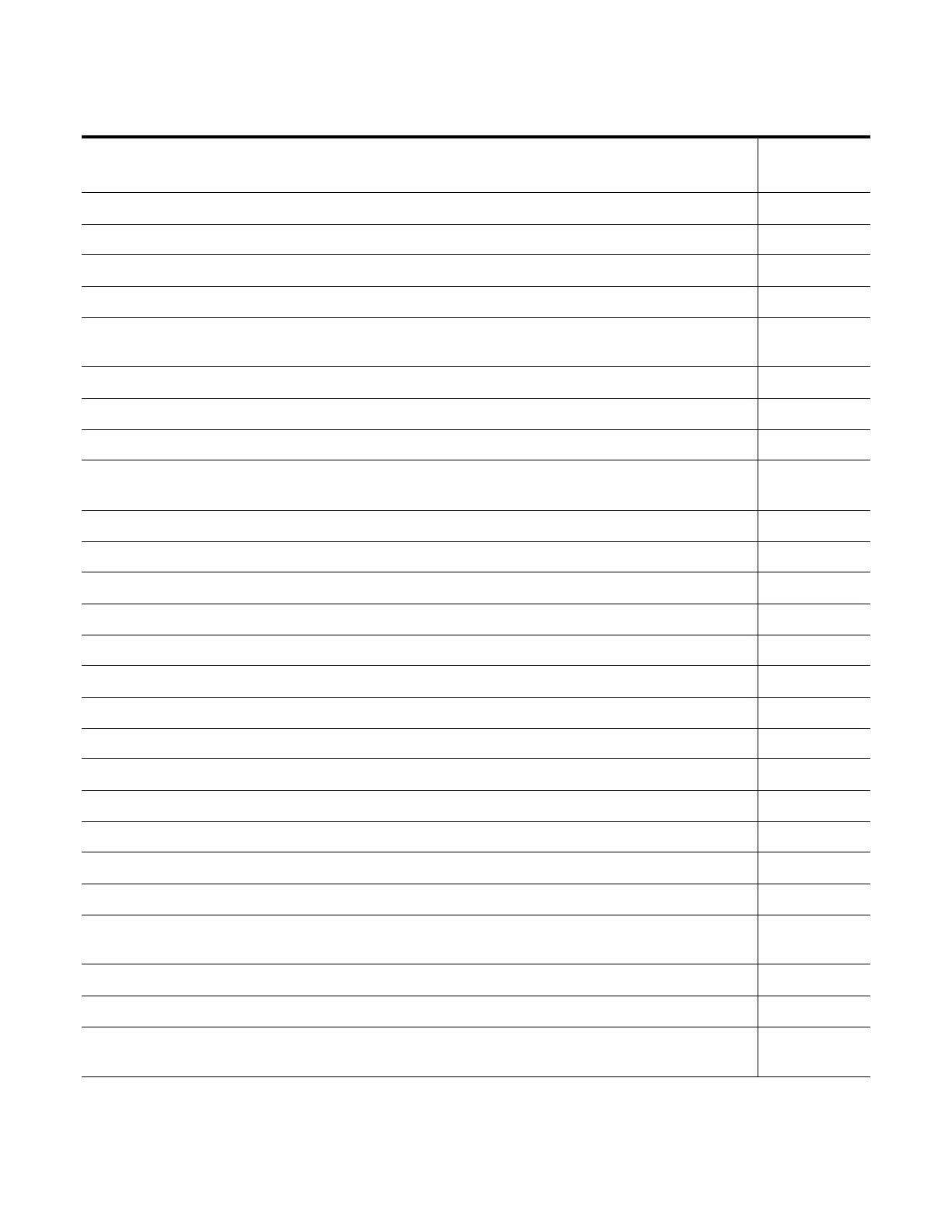

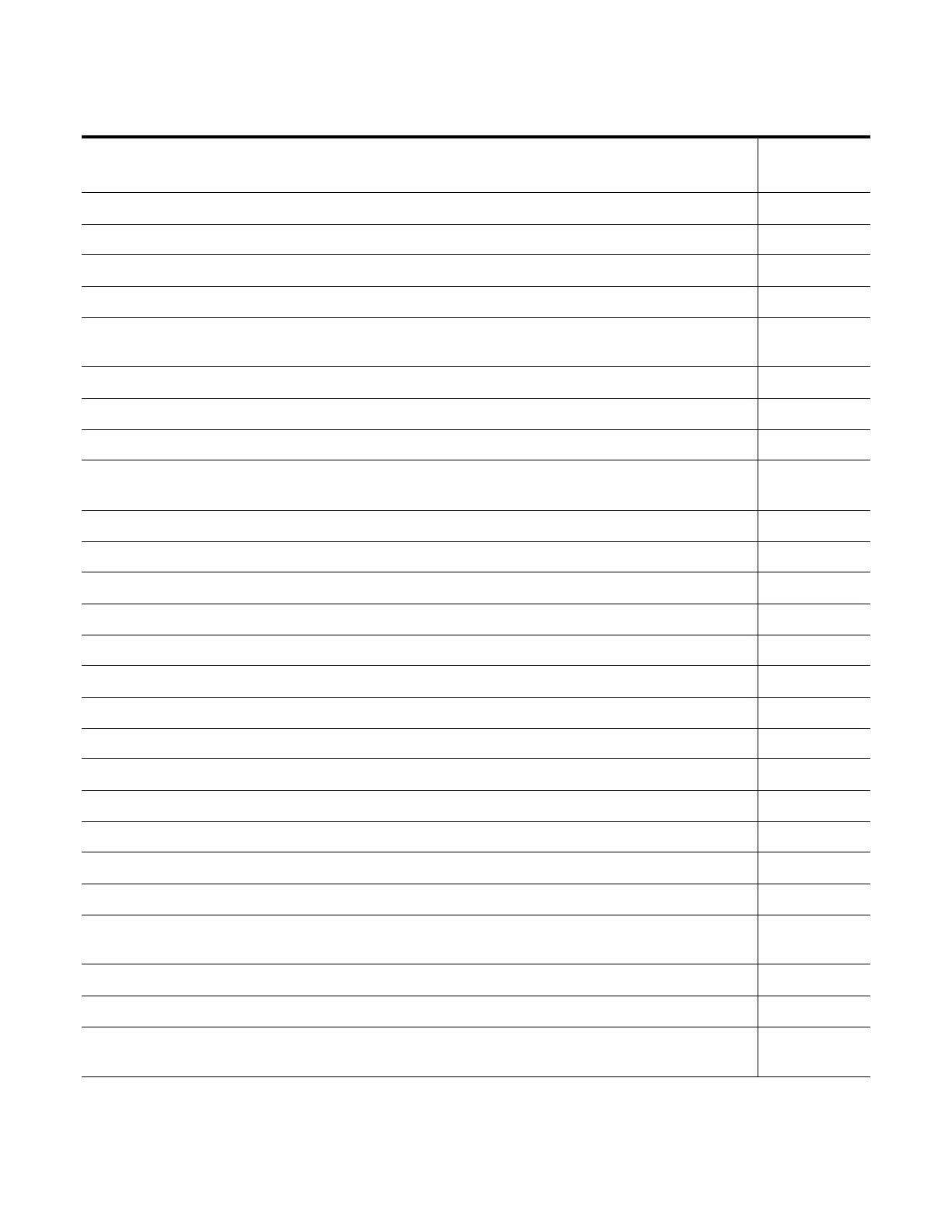

6-3

Routine Maintenance Operator Manual 122997-341

4.0 CHAMBER COMPONENTS (Cont’d)

4.5 Verify interior light. Replace if necessary. 6 x/yr

4.6 Check piping system for leaks. Repair if necessary.* 6 x/yr

4.7 Verify pump suction strainer for debris. Clean if necessary. 6 x/yr

4.8 If option is present, verify connections between riser valve and bottle washing cart is

secure.

3 x/yr

5.0 OSCILLATING JET SYSTEM

5.1 Inspect spray jets. Align and clean if necessary. 1 x/wk

5.2 Inspect spray headers. Flush out if necessary. 1 x/wk

5.3 Inspect oscillating carriage drive and clutch system. Test clutch for slippage.

Adjust if necessary.*

6 x/yr

5.4 Verify drive cable rollers for wear. Replace if necessary.* 6 x/yr

6.0 EACH SUPPLY-LINE STRAINER*

6.1 Inspect supply-line strainers for debris. Clean as necessary. 6 x/yr

7.0 EACH STEAM TRAP

7.1 Inspect steam trap for proper operation. 6 x/yr

8.0 AUTOMATIC DETERGENT INJECTION SYSTEM

8.1 Inspect and lubricate detergent supply and injection hose. Replace if necessary. 6 x/yr

8.2 Lubricate chemical injection pump rollers. 12 x/yr

8.3 Verify pickup tubes screen for debris. Clean as necessary.* 6 x/yr

8.4 Verify amount of detergent injected. 3 x/yr

9.0 OPTIONAL EXHAUST FAN

9.1 Grease fan bearings in two locations. 1 x/wk

10.0 SAFETY FEATURES

10.1 Verify warning plates inside wash chamber for legibility. If worn out, broken, or no longer

legible, replace with new ones.

3 x/yr

10.2 Test Emergency Stop cables for proper operation. 6 x/yr

11.0 FINAL TEST

11.1 Clean lint and dirt from components. every

inspection

*Contact STERIS for this service. Preventive Maintenance is not covered under warranty.

Table 6-1. Preventive Maintenance Schedule (Cont’d)

Recommended frequency of inspection is monthly. Usage, utility conditions may require

more or less frequent inspections. Tasks are defined on a yearly basis,

Min.

Frequency

Loading...

Loading...