Engine Mechanical: 1D-29

• Tighten the engine mounting damper stopper bolts (3)

to the specified torque.

Tightening torque

Engine mounting damper stopper bolt (a): 23 N·m

(2.3 kgf-m, 16.5 lbf-ft)

Valve Clearance Inspection and Adjustment

B931H21406019

Refer to “Valve Clearance Inspection and

Adjustment: in Section 0B”.

Camshaft Inspection

B931H21406020

Refer to “Engine Top Side Disassembly (Page 1D-18)”.

Refer to “Engine Top Side Assembly (Page 1D-22)”.

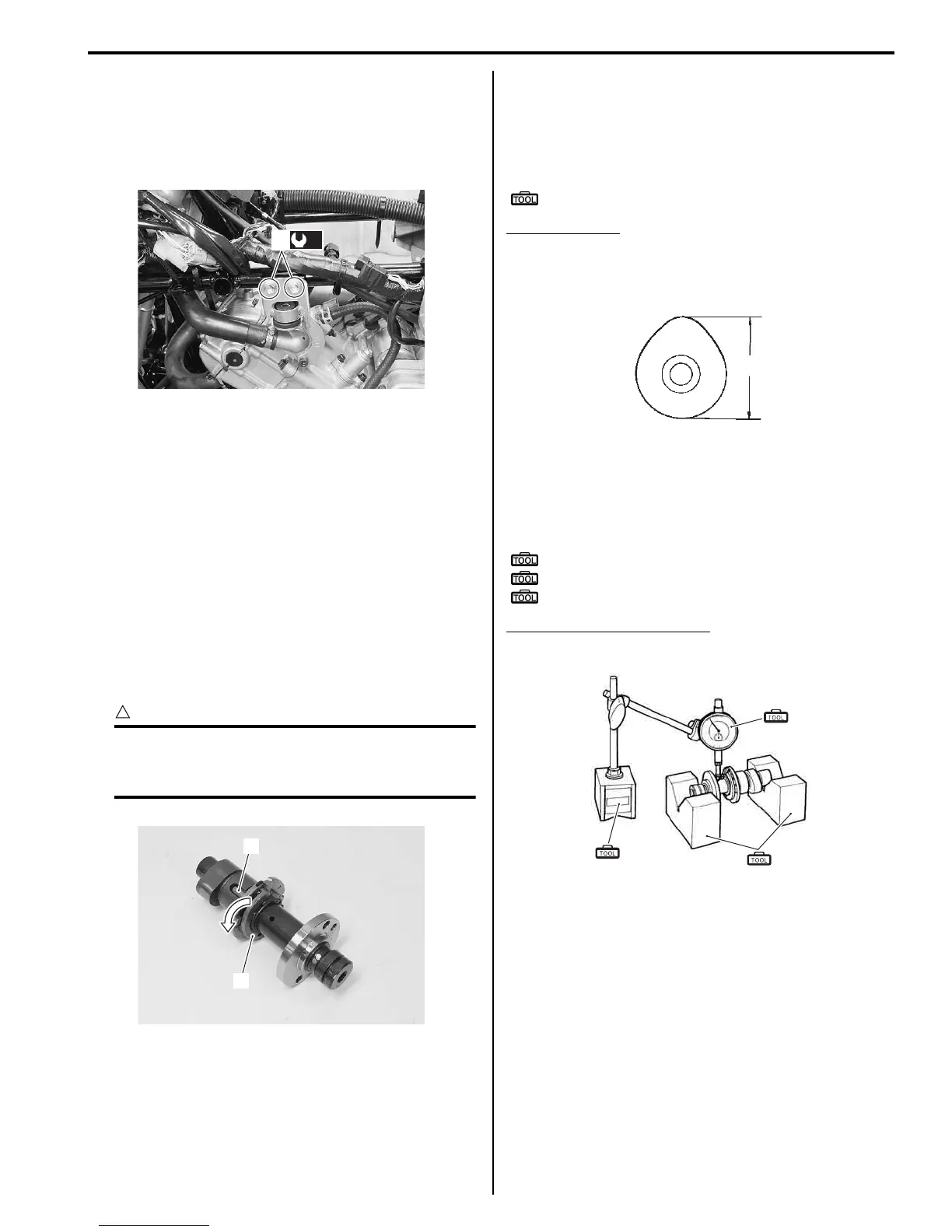

Automatic Decomp.

Inspection the decomp. control arm (1) moves smoothly

and decomp. cam (2) rotates together. If any abnormal

condition are found, replace the camshaft assembly with

a new one.

CAUTION

!

Do not attempt to disassemble the camshaft/

automatic decomp. assembly. It is not

serviceable.

Cam Wear

Check the camshaft for wear or damage.

Measure the cam height “a” with a micrometer.

Replace a camshaft if the cams are worn to the service

limit.

Special tool

: 09900–20202 (Micrometer (25 – 50 mm))

Cam height “a”

Service limit (IN.): 33.15 mm (1.305 in)

Service limit (EX.): 33.17 mm (1.306 in)

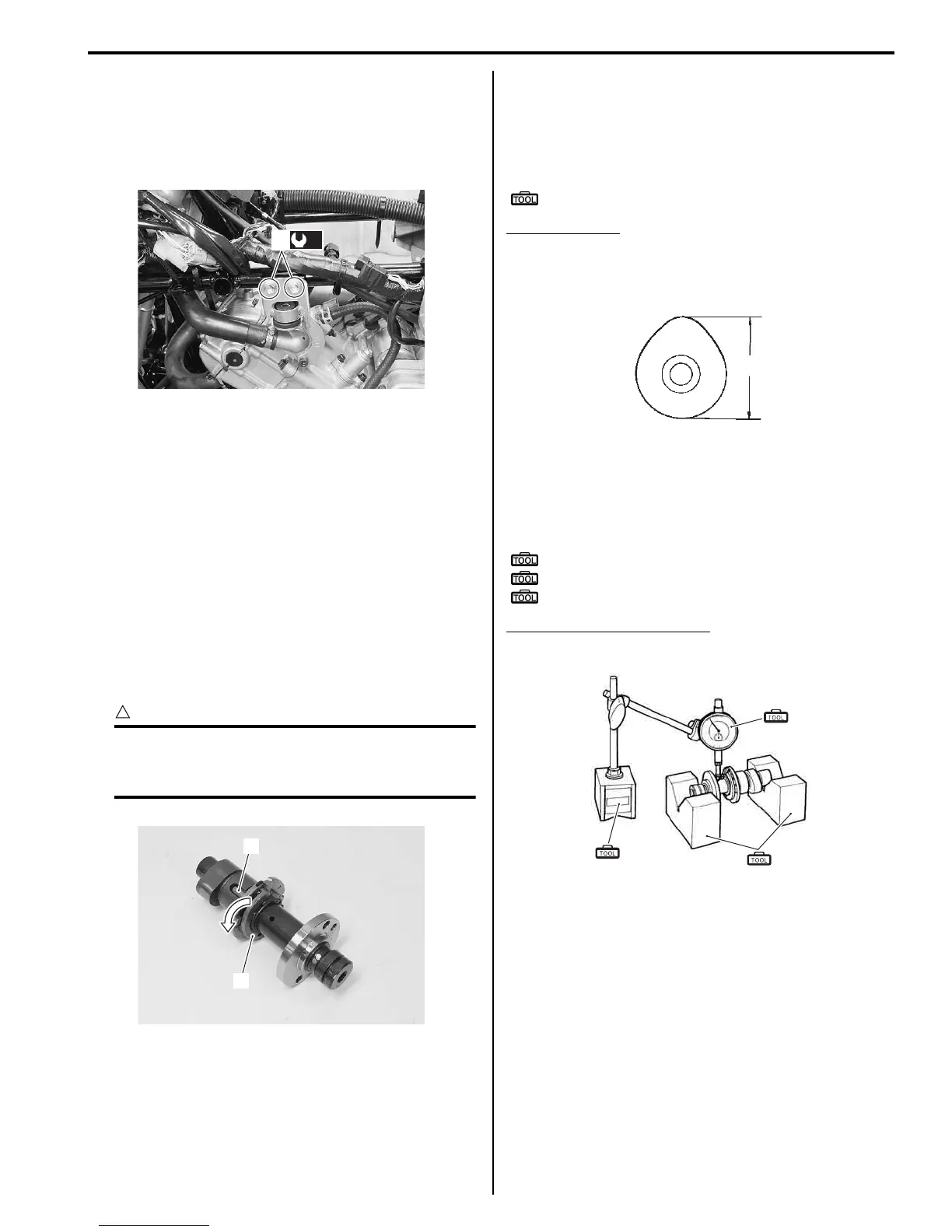

Camshaft Runout

Measure the runout using the dial gauge. Replace the

camshaft if the runout exceeds the limit.

Special tool

(A): 09900–20607 (Dial gauge)

(B): 09900–20701 (Dial gauge chuck)

(C): 09900–21304 (V blocks)

Camshaft runout (IN. & EX.)

Service limit: 0.10 mm (0.004 in)

(a)

3

I931H1140113-01

1

2

I931H1140115-01

“a”

I649G1140199-02

(B)

(C)

(A)

I931H1140116-01

Loading...

Loading...