Maintenance

7–18

1502C MTDR Service Manual

All other seals should be inspected during normal adjustment/calibration periods,

paying special attention to the front panel/case seal and option port seal.

CAUTION. If the case, option port, or a front panel control is removed, the

weathertight integrity of the instrument will be compromised.

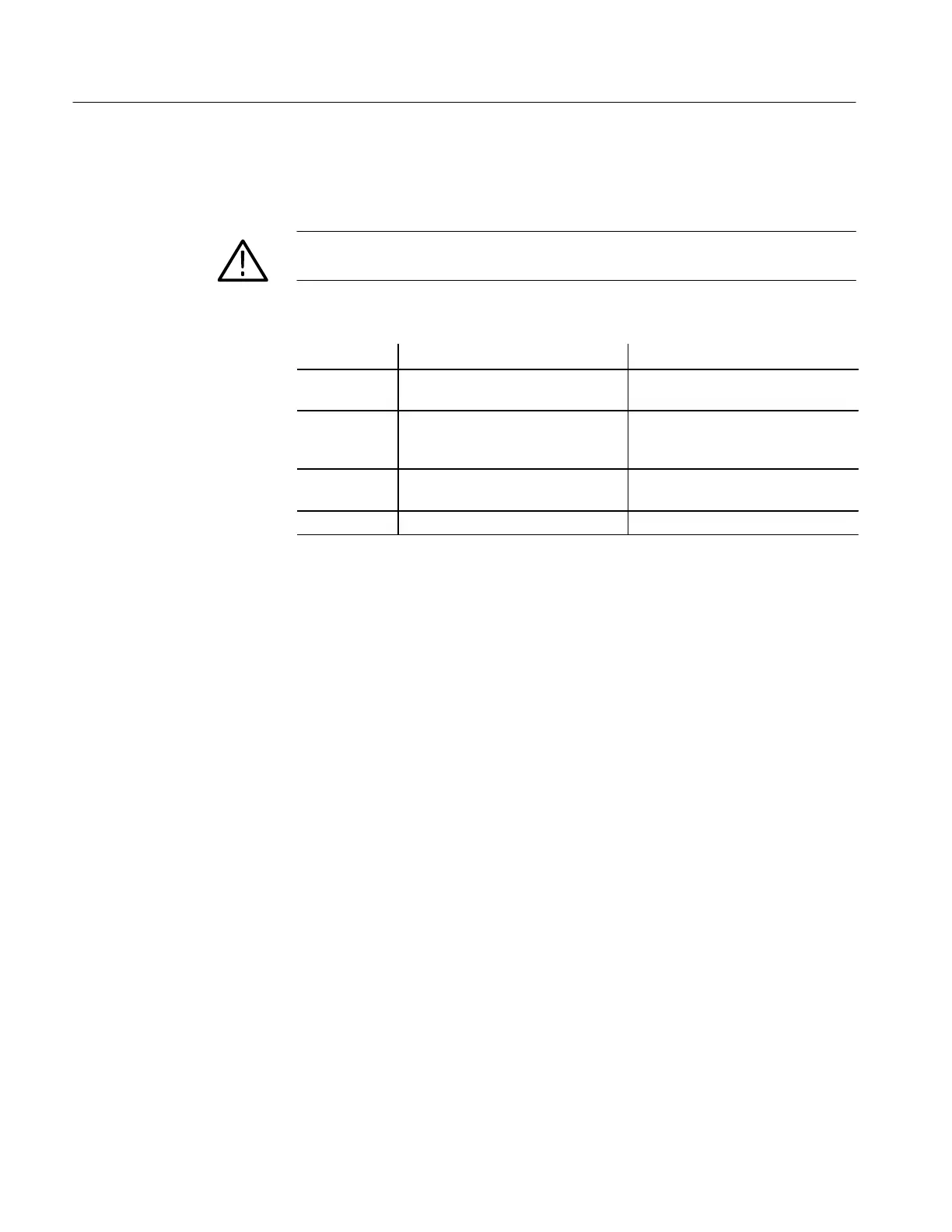

Tek Part No. Sealant Comments

006–2302–00 Dow Corning 3145 Adhesive Sealant Use to secure rubber boot around

buttons, implosion shield to front panel

252–0199–00 Dow Corning 3140 Coating Use to secure case gaskets to chassis

(more fluid sealant than 3145 with

24-hour cure time)

006–2207–00 GE G–661 Silicon Grease Light coating on case gaskets to pre-

vent sticking and provide a good seal

006–0034–00 Isopropyl alcohol Cleaning agent

If a rubber boot or gasket is replaced:

1. Remove the old gasket.

2. Remove all dried adhesive.

3. Clean area with alcohol and let dry.

4. Run a small bead of 3140 Coating/Adhesive in the cutout where the new gasket

will go.

5. Smooth the adhesive into an even, thin layer.

6. Clean the new gasket with alcohol and let dry.

7. Place the gasket on the adhesive and smooth into place. Make sure the edges are

secure and there are no air bubbles under the gasket.

8. Let dry for 24 hours before using or reassembling the front panel.

9. Use silicon grease on the outer side of the front panel gasket and the battery

gasket where they contact the instrument case.

The instrument rotary controls, the fuse and line voltage select access covers are

sealed with rubber O-rings. These are not glued in place, but should be inspected

and replaced if necessary.

Sealing Materials

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...