Maintenance—2230 Service

S CAUTION <

When checking a diode, do not use an ohmmeter

scale that has a high internal current. High current

may damage a diode. Checks on diodes can be per

formed in much the same manner as those on

transistor emitter-to-base junctions. Do not check

tunnel diodes or back diodes with an ohmmeter; use

a dynamic tester, such as the TEKTRONIX S76

Curve Tracer.

DIODES. A diode can be checked for either an open or

a shorted condition by measuring the resistance between

terminals with an ohmmeter set to a range having a low

internal source current, such as the R X 1 kfl range. The

diode resistance should be very high in one direction and

much lower when the meter leads are reversed.

Silicon diodes should have 0.6 V to 0.8 V across their

junctions when conducting; Schottky diodes about 0.2 V

to 0.4 V. Higher readings indicate that they are either

reverse biased or defective, depending on polarity.

RESISTORS. Check resistors with an ohmmeter. Refer

to the “ Replaceable Electrical Parts” list for the tolerances

of resistors used in this instrument. A resistor normally

does not require replacement unless its measured value

varies widely from its specified value and tolerance.

INDUCTORS. Check for open inductors by checking

continuity with an ohmmeter. Shorted or partially shorted

inductors can usually be found by checking the waveform

response when high-frequency signals are passed through

the circuit.

CAPACITORS. A leaky or shorted capacitor can best

be detected by checking resistance with an ohmmeter set

to one of the highest ranges. Do not exceed the voltage

rating of the capacitor. The resistance reading should be

high after the capacitor is charged to the output voltage of

the ohmmeter. An open capacitor can be detected with a

capacitance meter or by checking whether the capacitor

passes ac signals.

12. Repair and Adjust the Circuit

If any defective parts are located, follow the replace

ment procedures given under “Corrective Maintenance" in

this section. After any electrical component has been

replaced, the performance of that circuit and any other

closely related circuit should be checked. Since the power

supplies affect all circuits, performance of the entire instru

ment should be checked if work has been done on the

power supplies or if the power transformer has been

replaced. Readjustment of the affected circuitry may be

necessary. Refer to the “ Performance Check” and

“ Adjustment Procedure," Sections 4 and 5 of this manual

and to Table 5-1 (Adjustment affected by repairs).

DIAGNOSTICS

Introduction

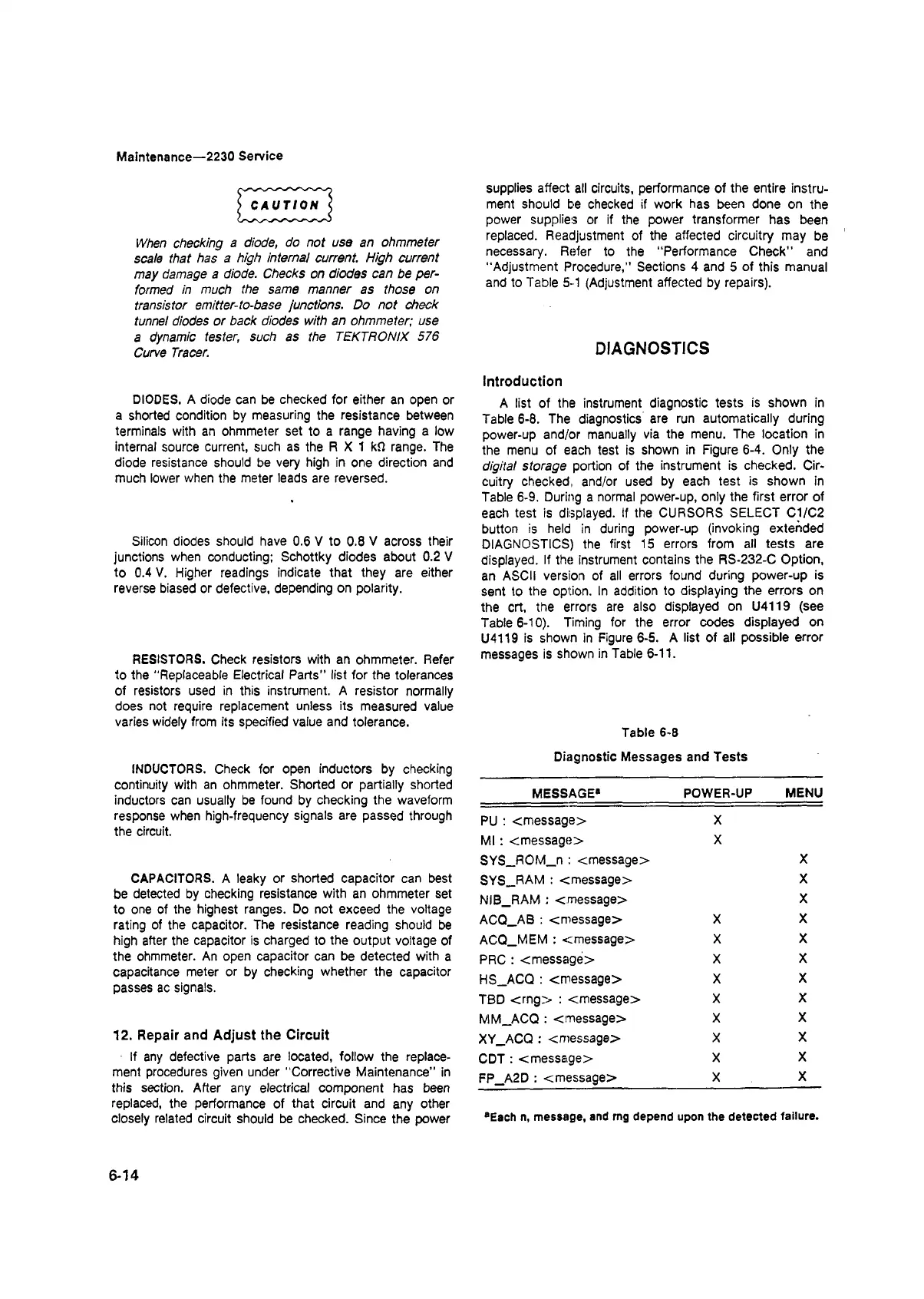

A list of the instrument diagnostic tests is shown in

Table 6-8. The diagnostics are run automatically during

power-up and/or manually via the menu. The location in

the menu of each test is shown in Figure 6-4. Only the

digital storage portion of the instrument is checked. Cir

cuitry checked, and/or used by each test is shown in

Table 6-9. During a normal power-up, only the first error of

each test is displayed. If the CURSORS SELECT C1/C2

button is held in during power-up (invoking extended

DIAGNOSTICS) the first 15 errors from all tests are

displayed. If the instrument contains the RS-232-C Option,

an ASCII version of all errors found during power-up is

sent to the option. In addition to displaying the errors on

the crt, the errors are also displayed on U4119 (see

Table 6-10). Timing for the error codes displayed on

U4119 is shown in Figure 6-5. A list of all possible error

messages is shown in Table 6-11.

Table 6-8

Diagnostic Messages and Tests

MESSAGE*

POWER-UP MENU

PU : <message>

X

M l: <message>

X

SYS_ROM_n : < message >

X

SYS_RAM : <message>

X

NIB_RAM : <message>

X

ACQ_AB : <message>

X

X

ACQ_MEM : <message>

X

X

PRC : <message>

X

X

HS_ACQ : <message>

X

X

TBD <rng> : <message>

X

X

MM_ACQ : <message>

X

X

XY_ACQ : <message>

X

X

CDT : <message>

X

X

FP_A2D : <message>

X

X

aEach n, message, and rng depend upon the detected failure.

6-14

Loading...

Loading...