Options—2230 Service

(power failing), interrupts are generated to tell the

Microprocessor that instrument power is going down. A

LO FAIL is also delayed by U1132C, D, and associated cir

cuitry, making STANDBY LO. This places the RAM in the

low current standby operating mode.

PERFORMANCE CHECK

PROCEDURE

Introduction

This part of Section 7 contains the GPIB Option and

RS-232-C portion of the instrument’s performance check

procedures. The "Performance Check Procedure” is used

to check the GPIB Option performance against the

requirements listed in Table 7-4. It is not necessary to

remove the instrument cover to accomplish any of the per

formance checks.

The Option performance check intervals are identical to

the basic instrument as indicated in "Performance Check

Interval” in the "Performance Check Procedure" Section 4

of this manual.

Limits and Tolerances

The limits and tolerances stated in this procedure are

GPIB and RS-232-C specifications only if they are listed in

the "Performance Requirements” column of Table 7-4.

The tolerances given in this procedure are valid for an

instrument that is operating in and has been previously

calibrated in an ambient temperature between +20°C and

+30'C. The instrument also must have had at least a 20-

minute warm-up period. Refer to Table 7-4 for tolerances

applicable to an instrument that is operating outside this

temperature range. All tolerances specified are for the

instrument only and do not include test-equipment error.

When performing either the GPIB or the RS-232 checks, it

is assumed that the standard instrument meets all of its

"Performance Requirements” as stated in the

"Specification” (Section 1) of the Service manual.

Test Equipment Required

Test equipment listed in Table 7-37 is required to per

form this procedure. Test equipment specifications I

described in Table 7-37 are the minimum necessary to pro

vide accurate results. Therefore, equipment used must

meet or exceed the listed specifications. Detail operating

instructions for test equipment are not given in this pro

cedure.

When equipment other than that recommended is used,

control settings of the test setup may need to be altered.

If the exact item of equipment given as an example in

Table 7-37 is not available, check the "Minimum

Specification” column to determine if any other available

test equipment might suffice for the performance check

procedure.

1. GPIB Performance Check

a. Set the RS-232-C Parameter switch to match the

requirements of your controller, GPIB Address 1.

b. Set the oscilloscope's front panel controls to obtain

a baseline trace.

c. Set the oscilloscope’s POWER button to OFF and

then to ON.

d. CHECK—The SRQ indicator is on when the power-

up sequence is finished.

e. Connect the Controller via GPIB cable to the IEEE

STD 488 PORT connector.

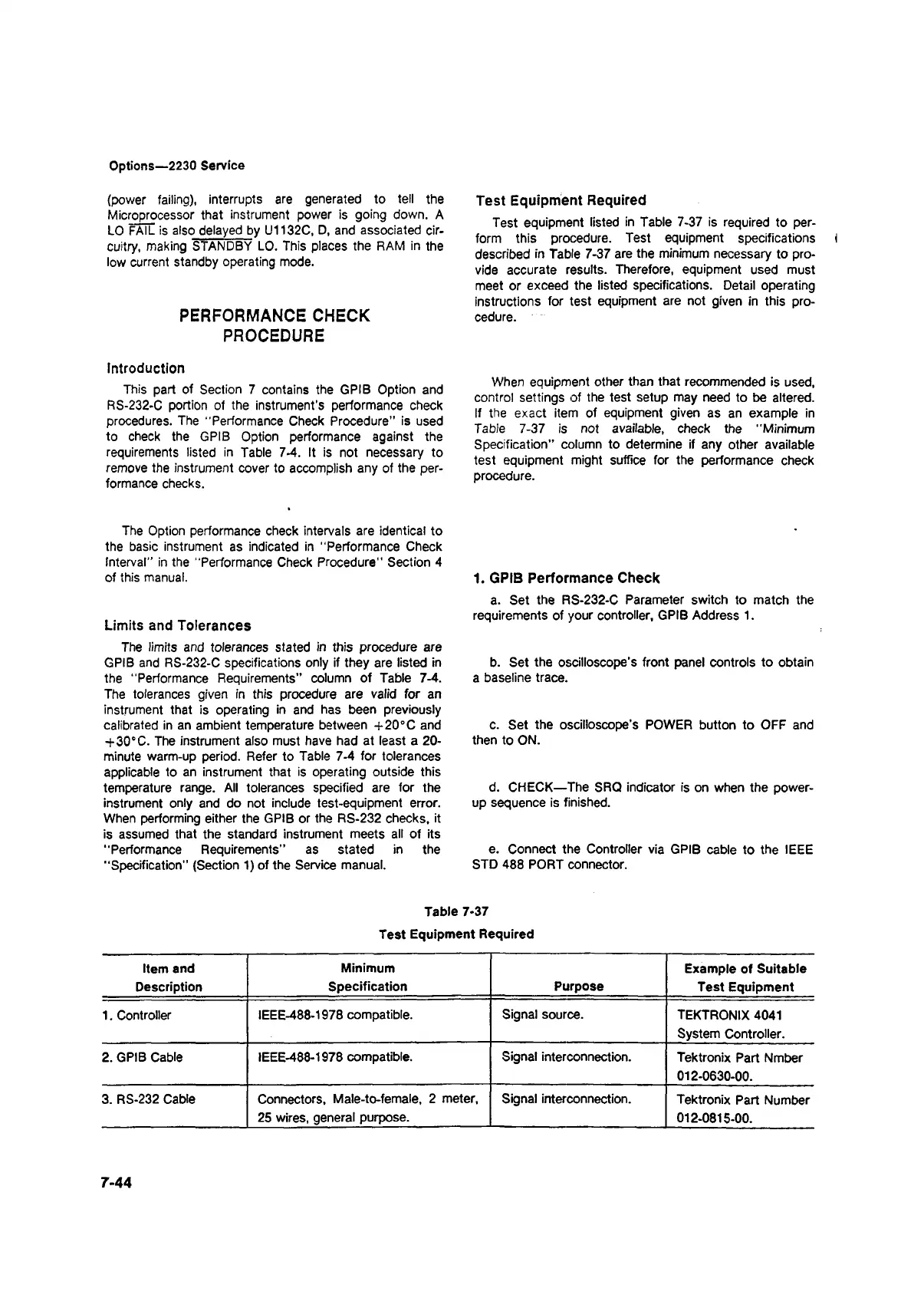

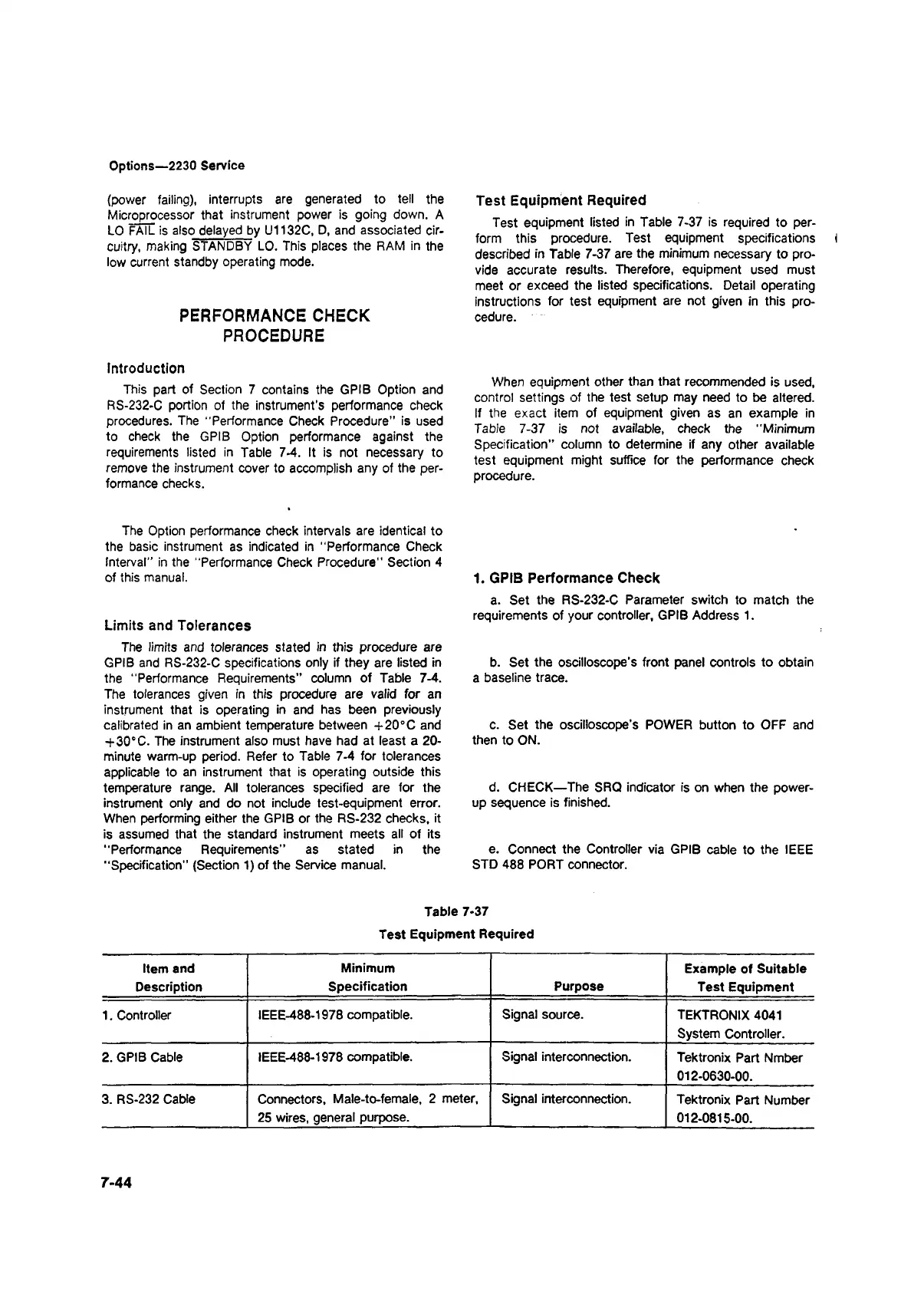

Table 7-37

Test Equipment Required

Item and

Description

Minimum

Specification Purpose

Example of Suitable

Test Equipment

1. Controller IEEE-488-1978 compatible.

Signal source.

TEKTRONIX 4041

System Controller.

2. GPIB Cable

IEEE-488-1978 compatible.

Signal interconnection.

Tektronix Part Nmber

012-0630-00.

3. RS-232 Cable

Connectors, Male-to-female, 2 meter,

25 wires, general purpose.

Signal interconnection.

Tektronix Part Number

012-0815-00.

7-44

Loading...

Loading...