141

Watchdog Timer Plus (WDT+)

At present, any commercial/industrial/professional electronic good must pass a number of tests and

obtain some certifications before its introduction to market, most notably CE, FCC, UL and TUV

certifications. This is so as it is imperative that a device pass Electromagnetic Compliance (EMC) test

not just for flawless performance but also for user safety. Hobby electronics projects don’t need these

and most hobbyists don’t fully understand the issues caused by EMI or what causes them. This is why

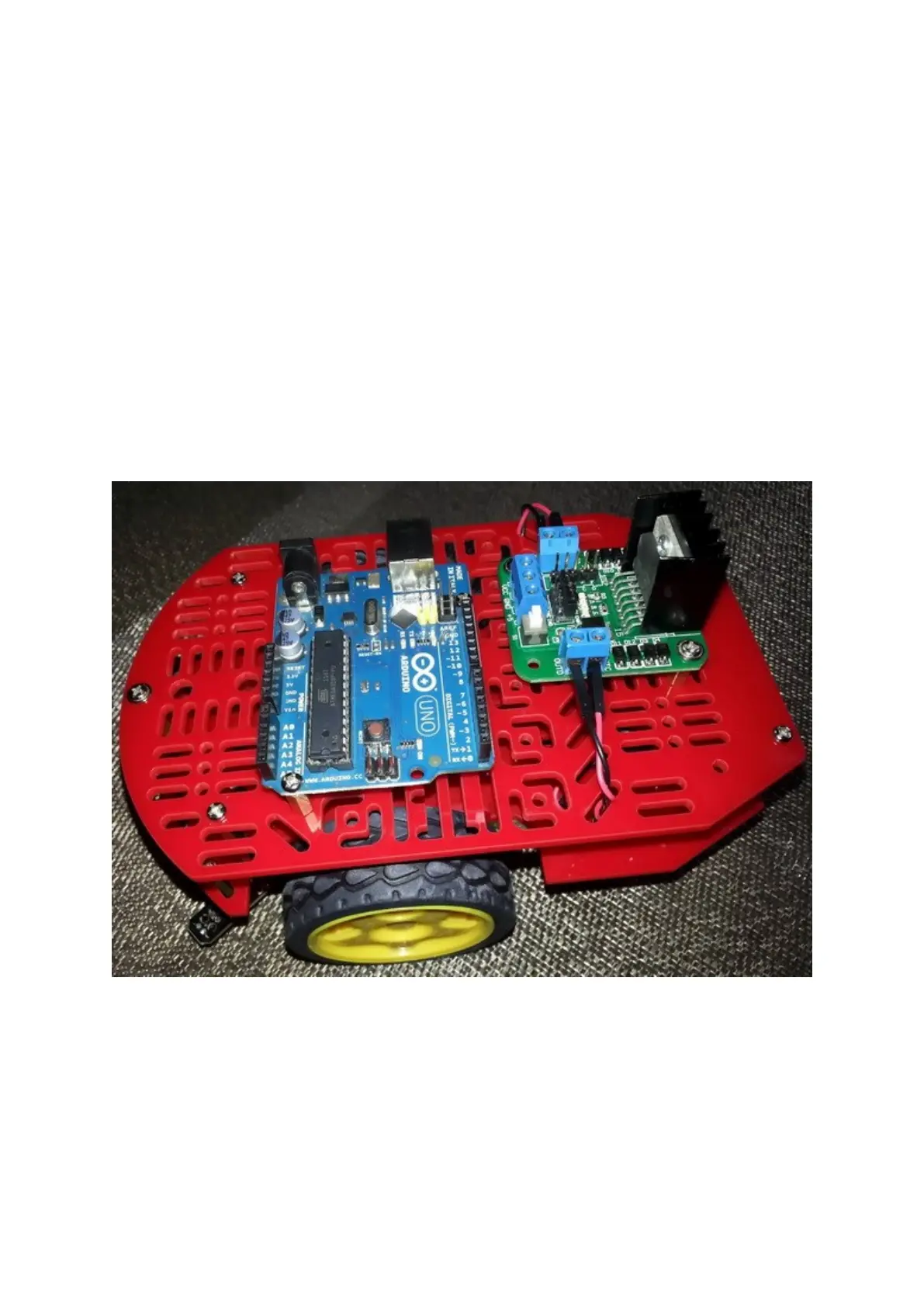

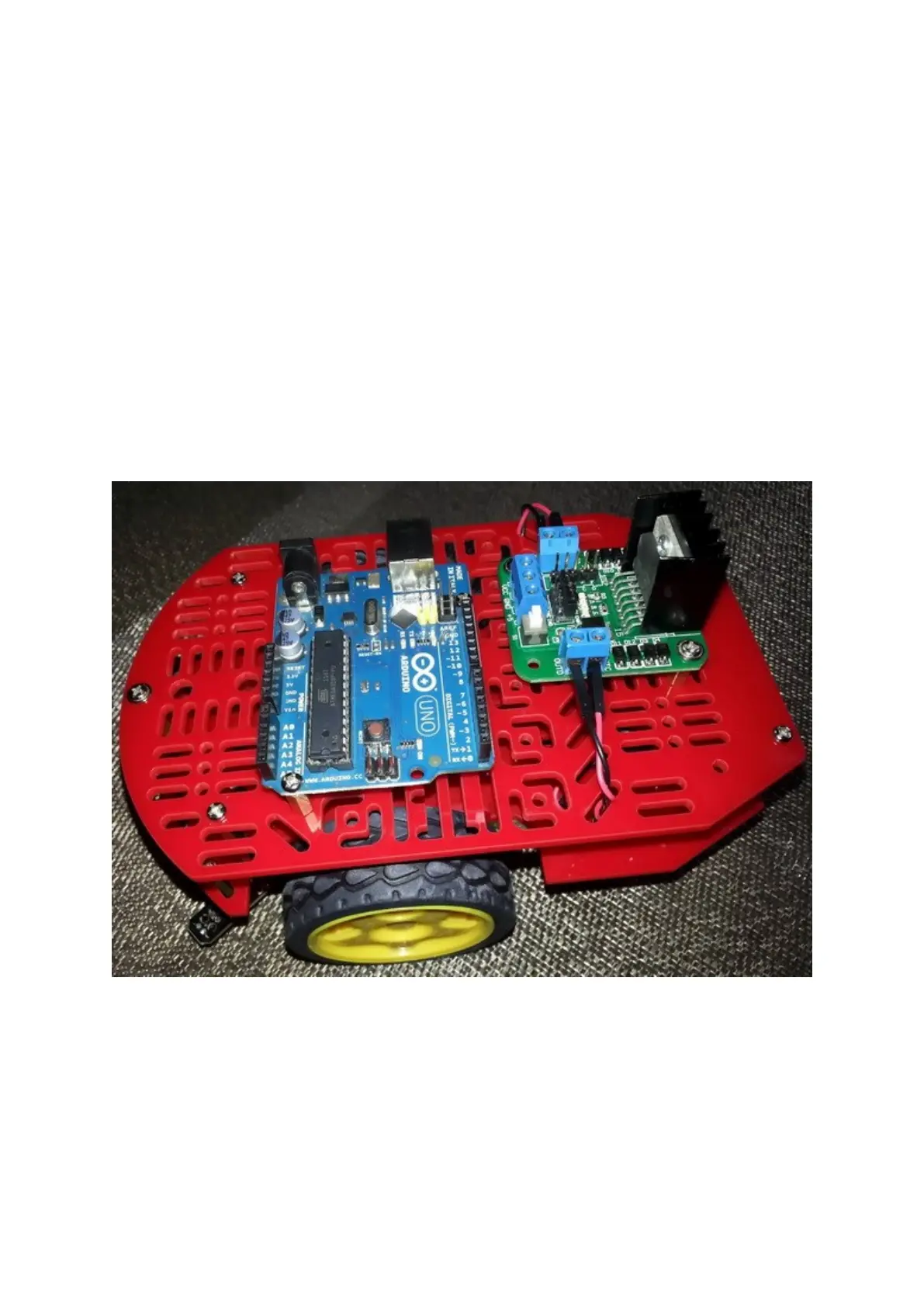

many simple robots like the line follower robot shown below fail to perform properly in robotics

competitions. Some of them seem to behave erratically while others seem to be unresponsive after

working for some time. If both hardware and software designs are well designed and tested against

harsh conditions, the chances of failure reduce significantly. A hardware designer should consider

proper PCB layout and component placement as well and component selection. Likewise, a

programmer should avoid polling-based solutions, blocking codes, unwanted loops, and should

consider using watchdog timers and other coding tricks. To avoid getting a device into a stalled state,

both hardware and software ends must merge properly and accordingly.

A watchdog timer is basically a fail-safe time. It is a very important module when considering an

embedded-system-based design that is likely to operate in noisy environments or when there is a

probability of its the application firmware to get stuck due to malfunctions. Any programmer would

want to get that stuck up firmware up and running again after recovering from the issue that cause it

to fail. All MSP430s are equipped with a WDT module and here we will see how it helps us in recovering

it when we simulate an entry into an unanticipated loop.

Loading...

Loading...