EX-TRAFIRE

®

45HD 4 Product description

EN - 13

4.3 Technical data for cutting torches FHT-EX

®

45TTH

and FHT-EX

®

45TTM

FHT-EX

®

cutting torches are used for manual and mechanical cutting,

gouging, and marking. They use compressed air or nitrogen to cut mild

steels, stainless steels, aluminum, and other electrically conductive metals.

They are connected to the cutting power supply using the Torch

Connection System (TCS).

The values below refer to the torches!

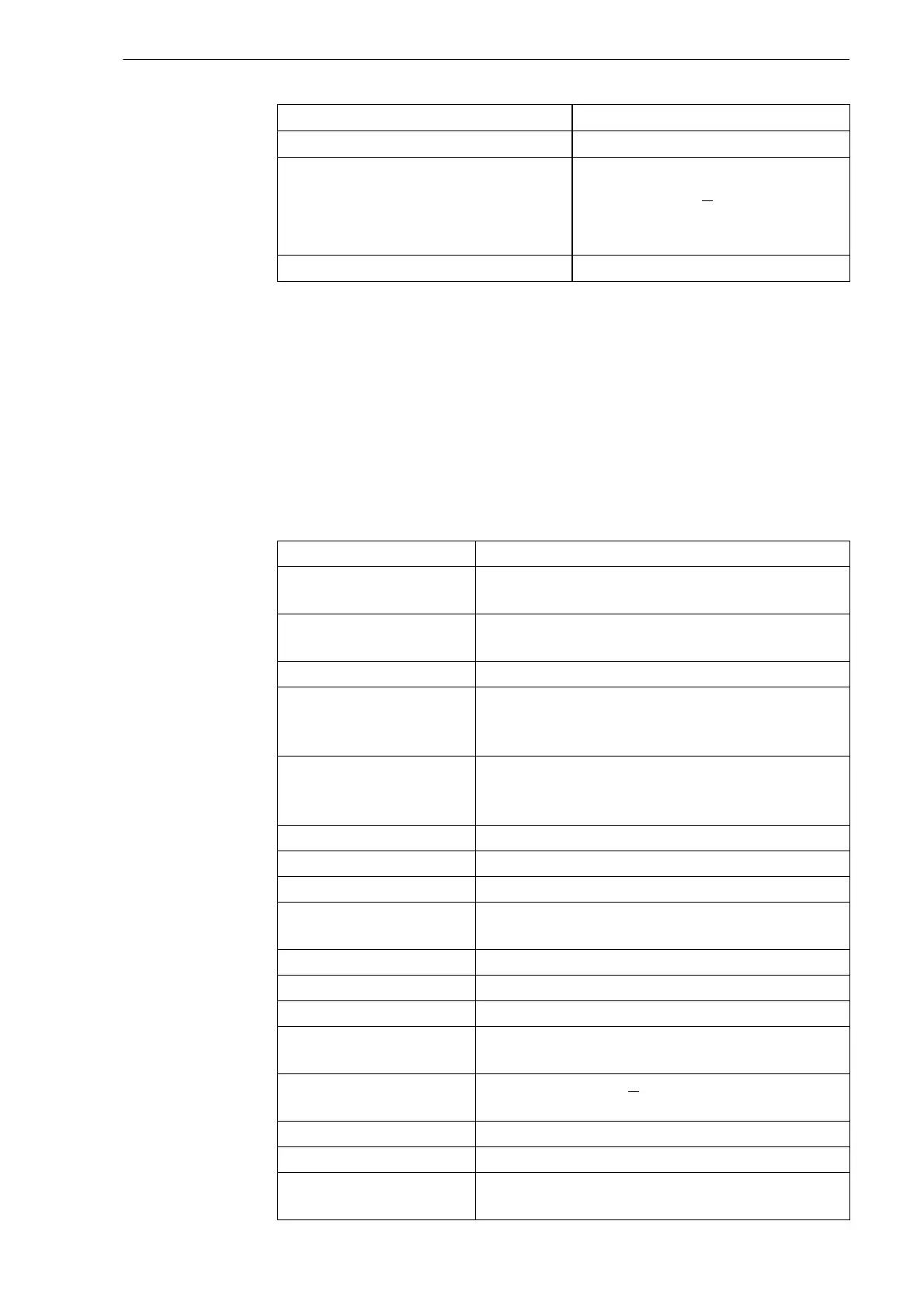

Table 5 Gas data

Permissible gas Compressed air/nitrogen/argon

Max. gas inlet pressure 10 bar

Recommended compressed air

quality

ISO 8573-1 Class 1.2.2.

Purity: >

99,99%

clean, and free from moisture and

oil

Max. flow rate 120 l/min at 10 bar

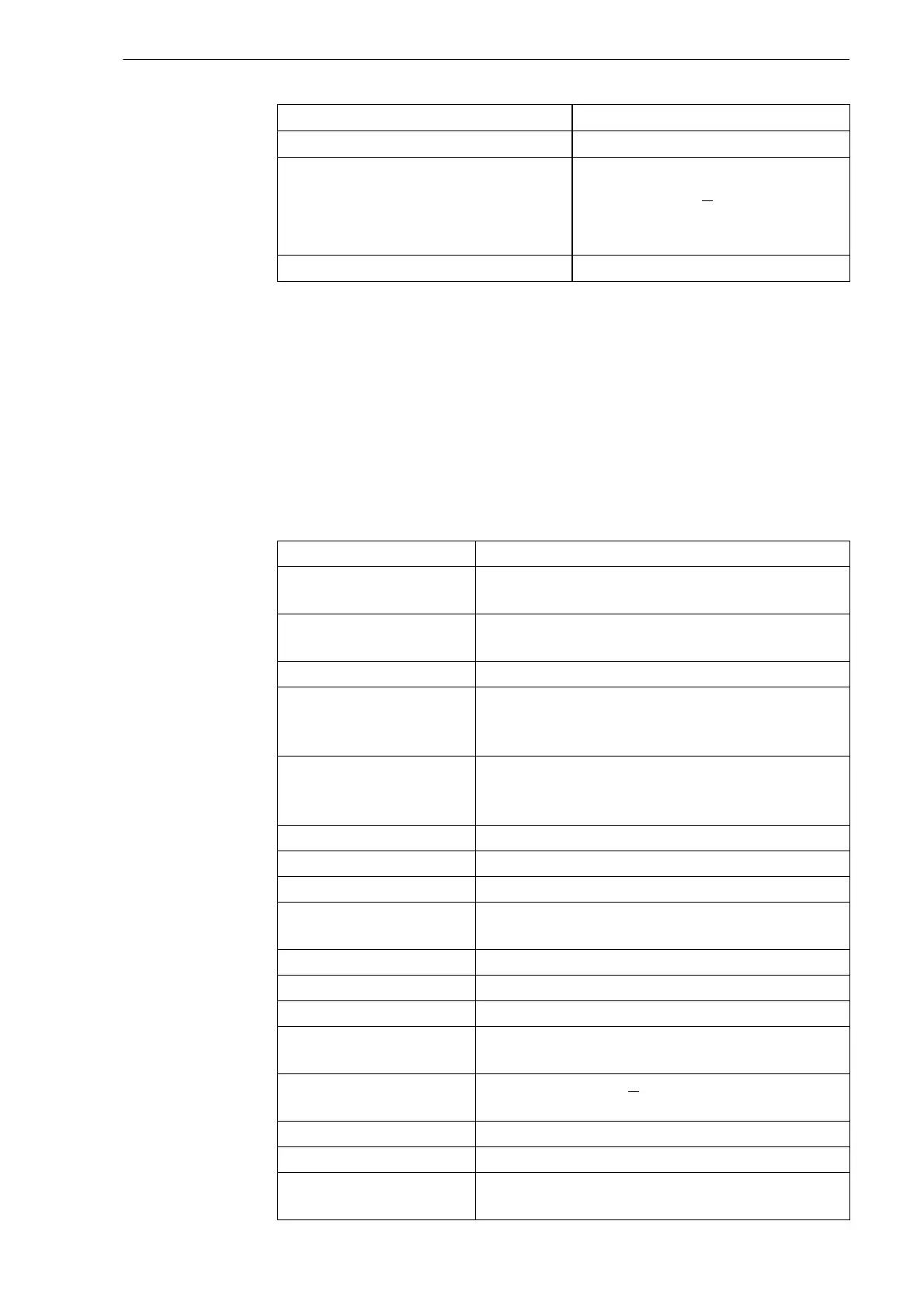

Table 6 Technical data for FHT-EX

®

45TTH and FHT-EX

®

45TTM cutting

torches

FHT-EX

®

45TTH / FHT-EX

®

45TTM

Recommended cutting

capacity

[mm]

12

Max. cutting capacity

[mm]

25

Piercing capacity

[mm] 10

Permissible ambient

temperature during

operation

-10° C to +40° C

Permissible ambient

temperature during

transport and storage

-25° C to +55° C

Relative humidity <90% at +20°C

Sub-menu item Plasma cutting, gouging, marking

Application type Manual and mechanical

Rated current and duty

cycle

45 A/100%

Permissible gas Compressed air/nitrogen

Flow rate 90 l/min. at 4.8 bar

Maximum pressure 10 bar

(Dynamic) operating

pressure

4.8 bar

Gas post-flow period

delay

>

20 sec.

Type of voltage DC

Voltage rating 500 V peak value

Protection type for

device

IP3X (EN 60529)

Loading...

Loading...