EX-TRAFIRE

®

45HD 9 Maintenance and cleaning

EN - 35

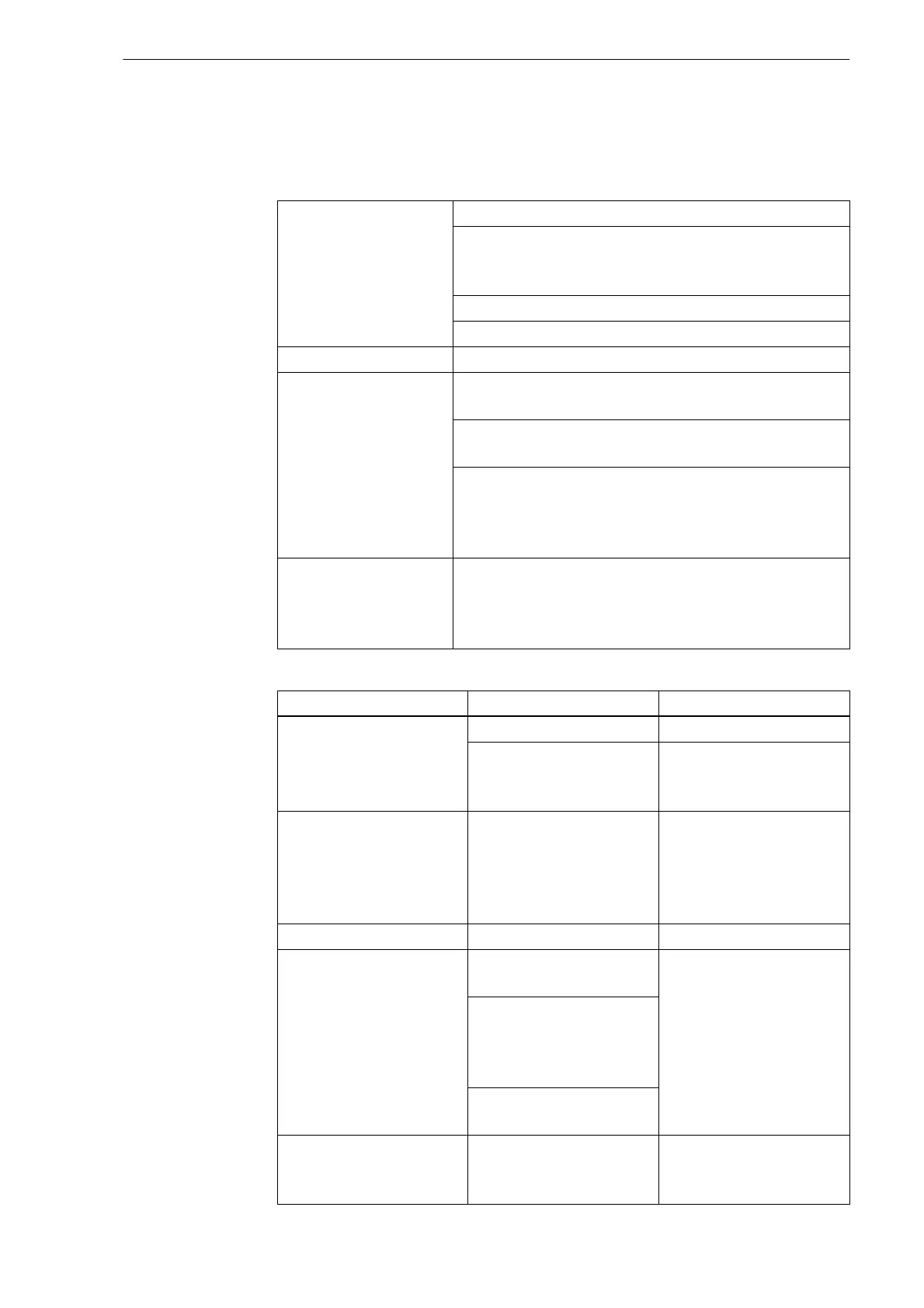

9.1 Maintenance and cleaning intervals

The specified intervals are standard values and refer to single-shift

operation. We recommend recording the inspections. The date of the

inspection, the detected defects and the name of the inspector should be

documented.

Daily/every 6 hours

of cutting

Check the gas settings.

Check cables, connector hoses, and

connections for tight fit and damage, and

replace if necessary.

Check the work lead clamp for contamination.

Check the cutting torch's consumables for wear.

Weekly Check the cap sensor.

Every 3 months

Check the cutting torch for signs of cracks in the

torch body and exposed wires.

Check the gas hose, filter elements and

connections for leaks.

Open the device body and have the inside of

the device cleaned with a vacuum cleaner or

dry, clean compressed air by Thermacut

®

or

another authorized specialist.

Annually and after

each time the

housing is opened

Have a safety inspection performed in

accordance with DIN IEC 60974 Part 4:

“Periodic inspection and testing” by Thermacut

®

or another authorized specialist.

Table 12 Parts inspection

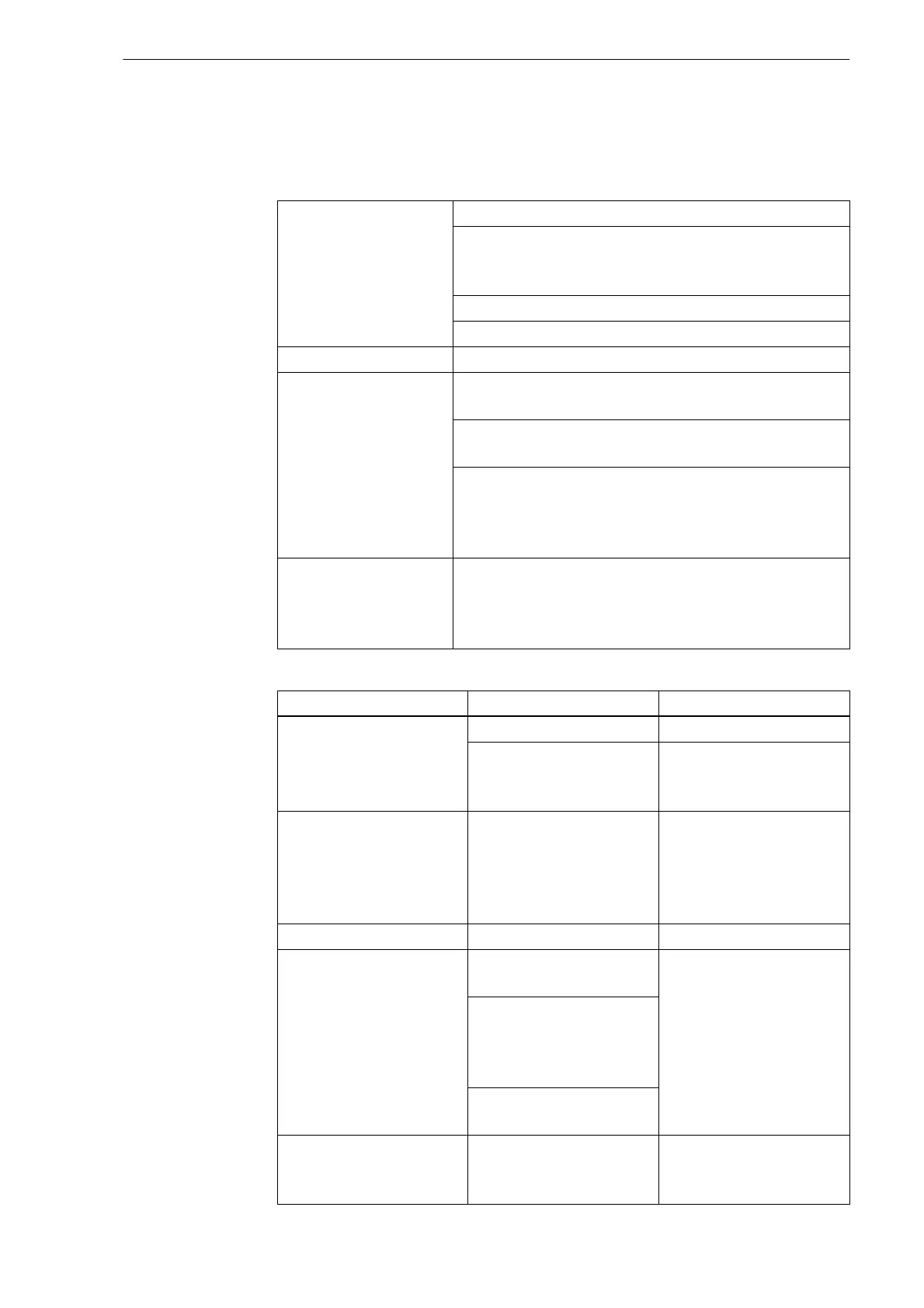

Consumable Check for Action

Shield

Orifice is not round. Replace the shield.

Spatter in the gap

between the shield

and the nozzle.

Clean the shield and

nozzle surface.

Retaining cap

Heat damage, cracks,

breaks, damaged

threaded

connections,

clogged gas holes.

Replace the retaining

cap.

Nozzle Orifice is not round. Replace the nozzle.

Swirl ring

Outer surface is

damaged or dirty.

Clean or replace the

swirl ring.

Electrode restriction

due to dirt, debris, or

damage on interior

surfaces.

Clogged or

damaged gas holes.

Electrode

Pit depth in hafnium

is deeper than

1.6 mm.

Replace the

electrode.

Loading...

Loading...