Engine Maintenance 9-53

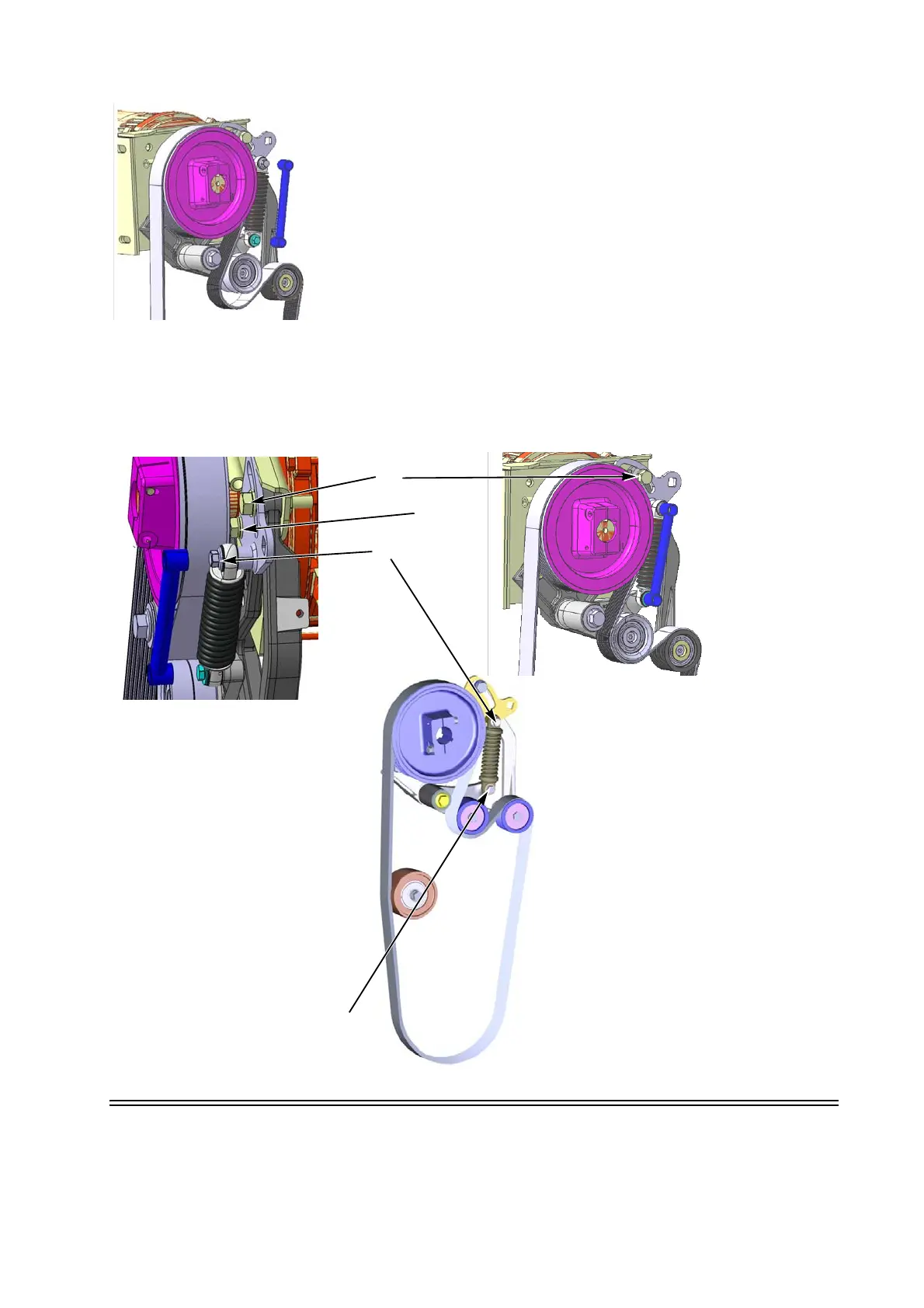

4.Adjust the position of the tensioning system: by using the square hole of the plate, rotate

the arm slowly down and compress the tensioner element until you can fit the gauge tool on

the 2 screw heads of the tensioner.

Warning: The gauge tool must not be locked on the screw heads but must move freely on

and off the head screws. Centre to centre dimension between screws of 139.0mm on

Tensioning Element to be verified by using checking Gauge (P/N: 2042436).

Note: P/N 2042436 is a checking gauge not a setting gauge & should not be used to hold

the dampener in position prior to tightening holding hardware.

5. Once the gauge tool fits perfectly and freely on the screw heads of the tensioner element, remove it and tighten the plate

screws (S2) and (S3) to lock the eccentric plate in that position.

After tightening of the plate screws, check the tensioner centre to centre distance again with the gauge tool and tighten the

screws (S4 and S5) to 22 Ft-lb ±2 Ft-lb

(30 Nm±3Nm).

Warning: Do not use the tensioning system if the gauge tool does not fit correctly on the tensioner.

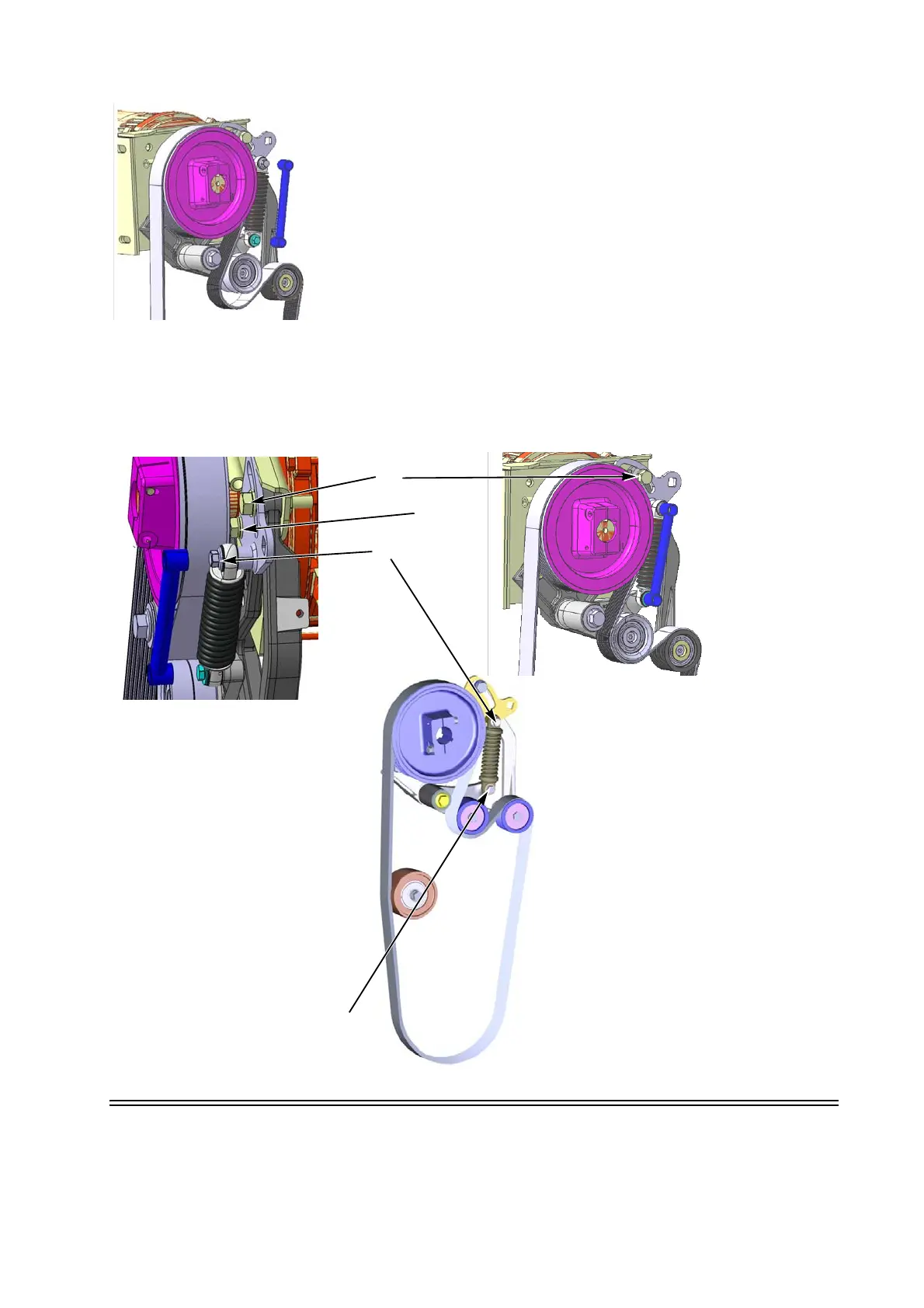

CLUTCH MAINTENANCE

Inspect the clutch every 6,000 hours of unit operation or yearly, whichever occurs first. Remove the clutch, clean the shoes and

drum, and regrease the bearings. Replace the bearings if they are worn. Inspect the drive bushings, anchor bushings, shoe lining

and springs for wear and replace if necessary.

Loading...

Loading...