Unit Description 5-6

OptiSet™ Option

µP-VI, SR-2 and SR-3 control systems include the OptiSet feature as standard. OptiSet allows each customer to program a set of

unit operating details for a specific setpoint or setpoint temperature range. When the unit setpoint falls within a programmed

setpoint range, all unit operation is automatically determined by the OptiSet settings for that setpoint range. Unit operating

features that can be programmed using the OptiSet feature include:

All optiset functions and features can be found and programmed using Optiset program tool and/or Wintrac 6.0 and later

service tool

Data Acquisition System (DAS) Option

A stand-alone data recorder with an independent memory and independent real-time clock is available to record up to 6

independent temperature sensors as well as setpoint and alarm codes from the unit controller to track temperature management

against setpoint. The DAS option can interface with TG-VI, µP-V, µP-VI and multi-temperature µP-IV controllers.

Remote Control Options (SR-3, SR-2, TG-V, µP-IV Multi-Temp, µP-V and µP-VI Controllers)

Remote controls are available for SR-3, SR-2, TG-V, µP-IV Multi-Temp, µP-V and µP-VI Controllers. Remote controls are used

to operate the unit from inside the trailer or the truck cab. The flush mount remote control is usually mounted in a wall inside the

trailer. The in-cab remote control is usually mounted in the dash of the truck cab.

Sequence of Operation

Engine Operation

Continuous Mode

• High Speed Cool

• Low Speed Cool

• Low Speed Heat

• High Speed Heat

2, 3

• Defrost

Note: Tables shown are for basic operation and can be used for basic diagnostic’s. However, these may change from this

owing the the basic programmable features configurations and/or optiset configurations.

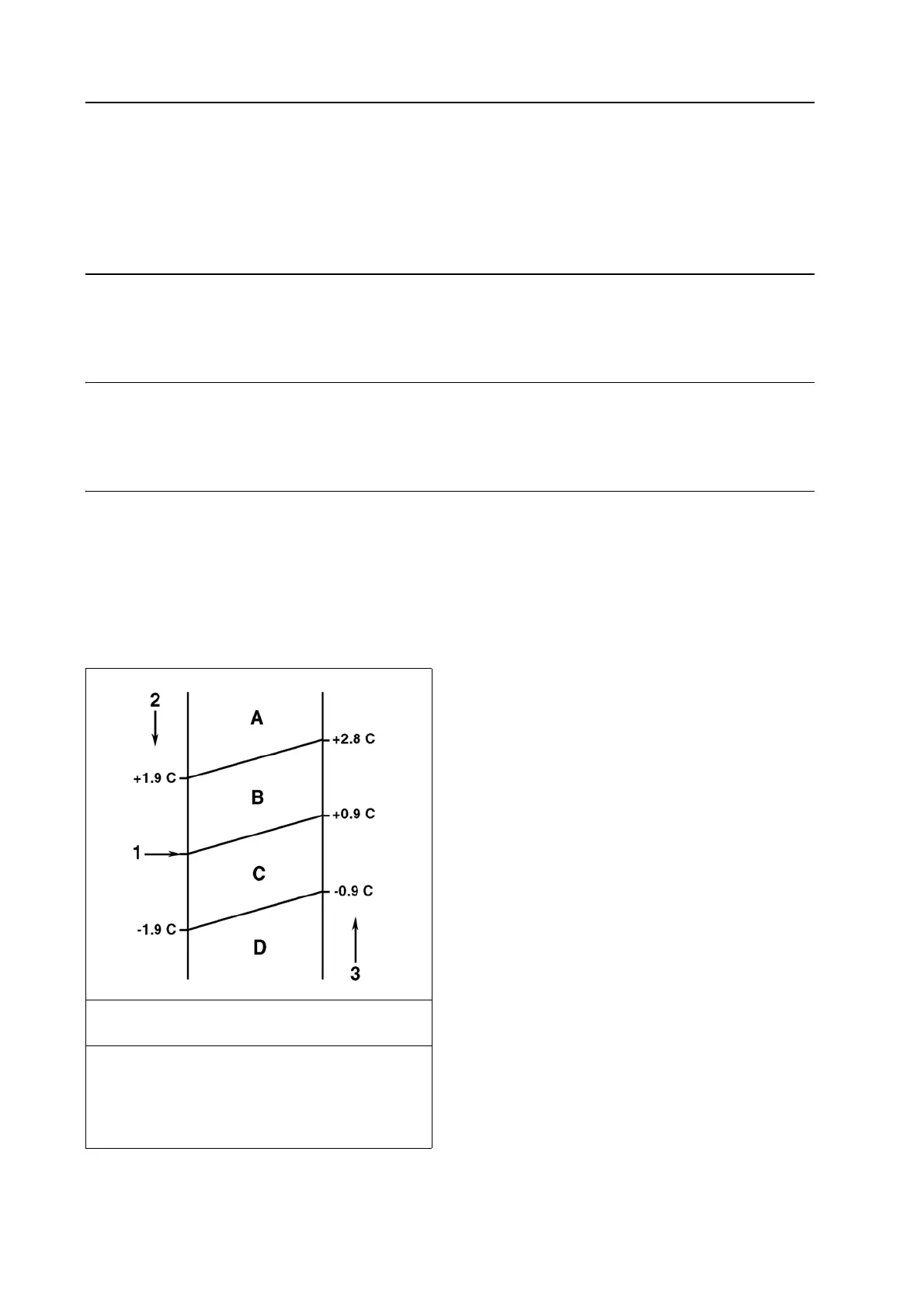

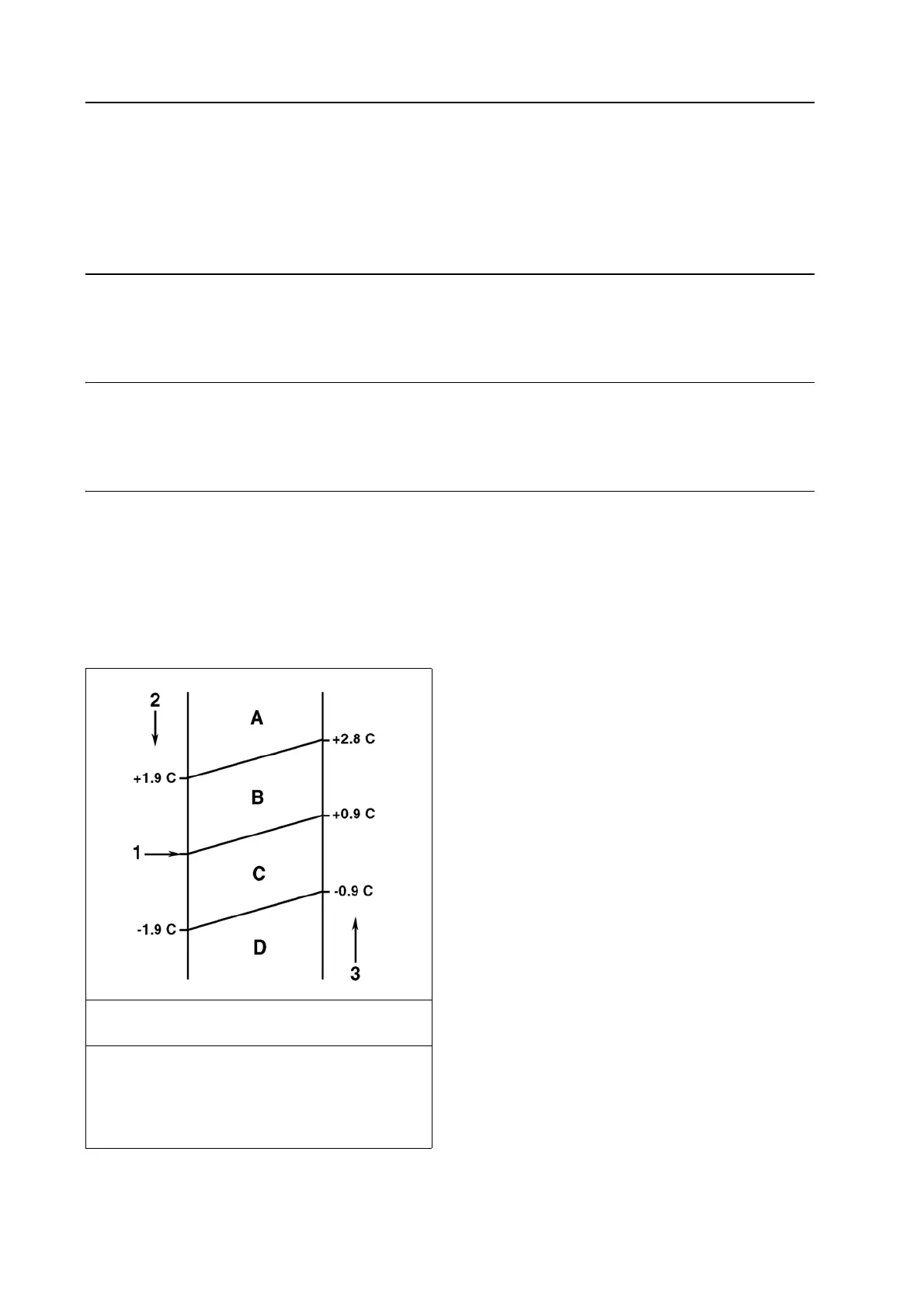

Basic Operating Modes – Continuous Run Engine

Operation

1. Setpoint

2. Temperature Decrease

3. Temperature Increase

A. High Speed Cool

2

B. Low Speed Cool

C. Low Speed Heat

D. High Speed Heat

2, 3

Loading...

Loading...