Rev. 000

HYDRAULIC LIFT ASSEMBLY

7-44

TX 413 Service Manual

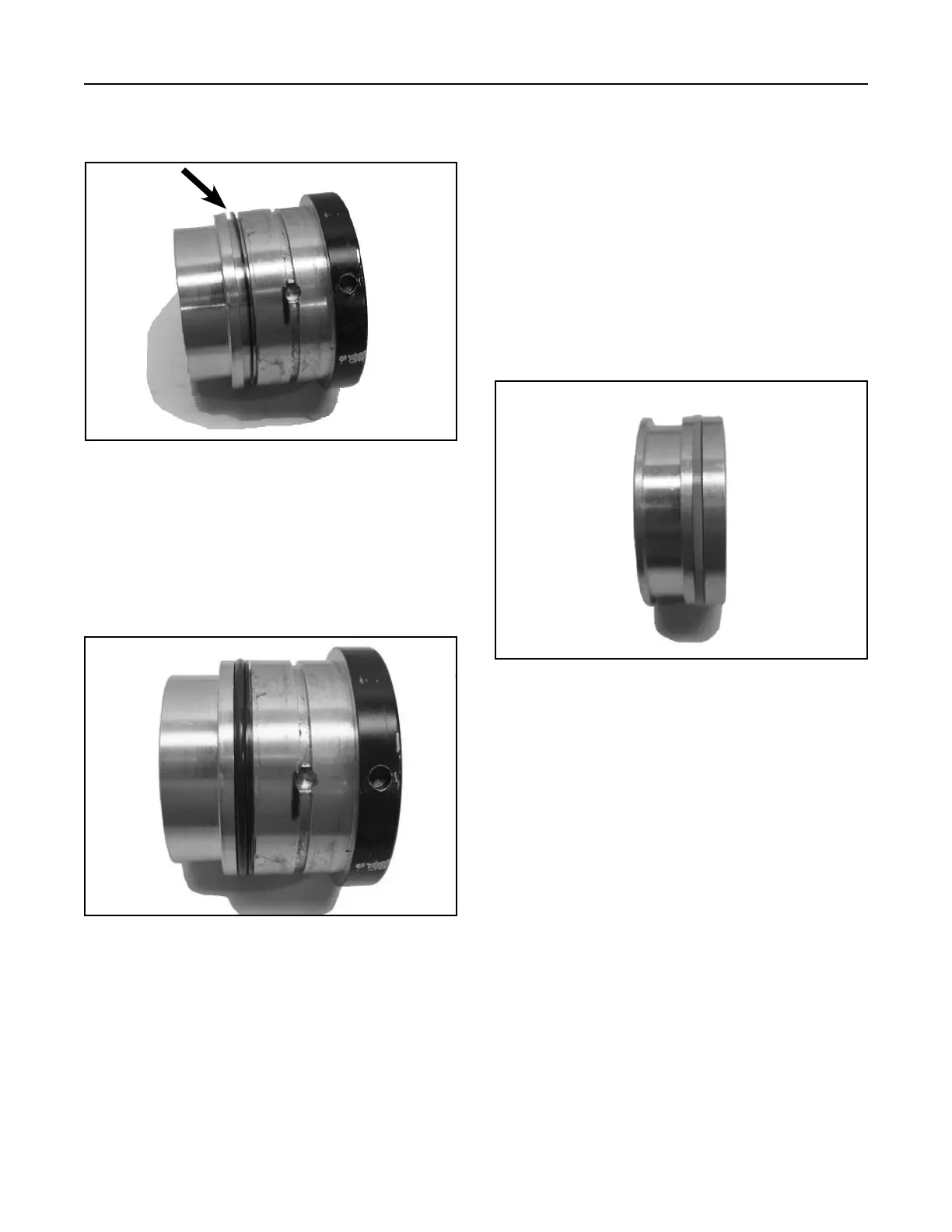

Figure 343 DSC-1359

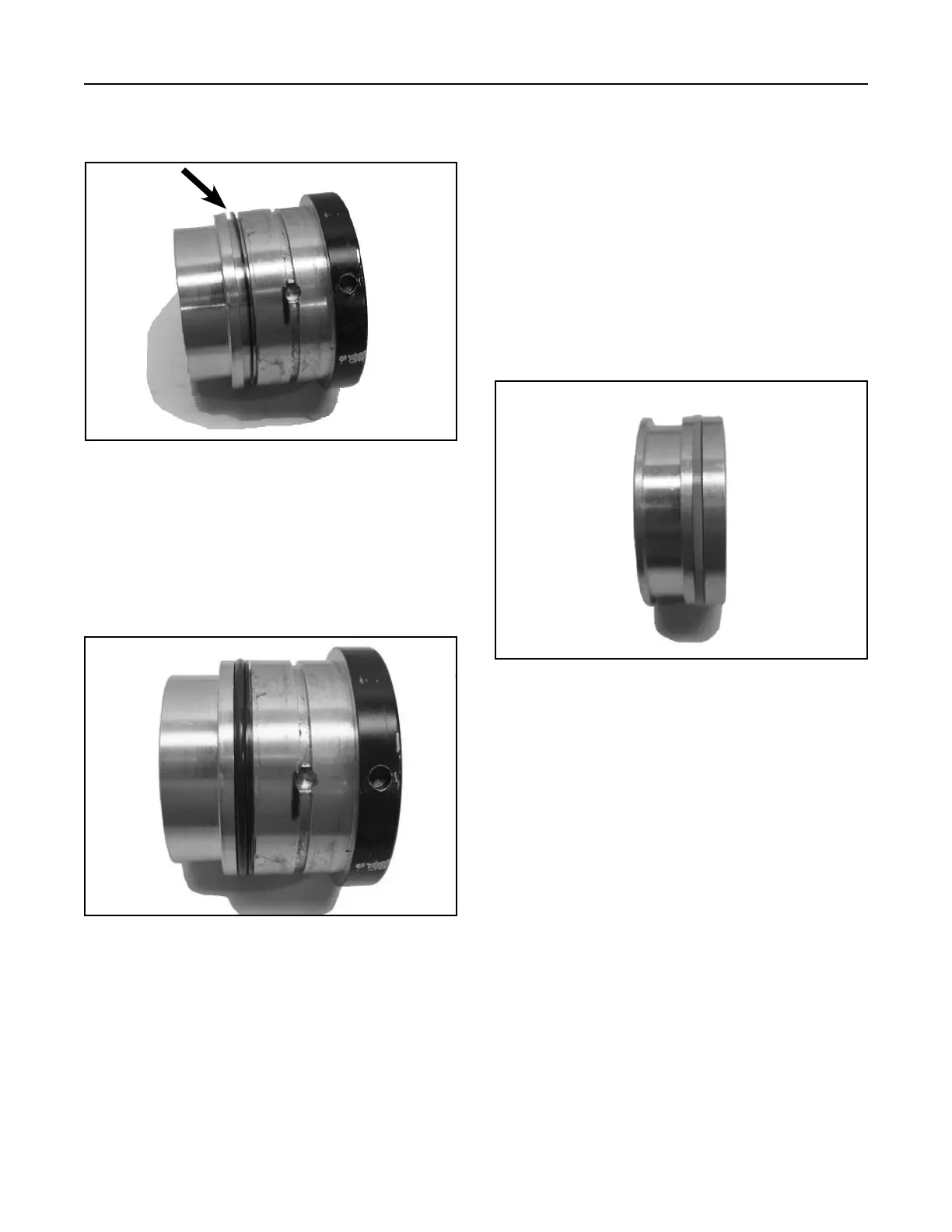

5. Next, install the O-ring around the groove, next to

the Static Back-up Ring (Fig. 342).

Note: If possible, the head/seal assembly should

sit for at least one hour to allow the seals

to normalize.

Figure 342 DSC-1356

6. For easiest installation, warm Bi-directional

Piston Seal (Teflon seal) in 120° to 150° F (48.9°

to 65.6°C) 10W-30 oil. Lubricate the piston and

all components with oil. Stretch the 0-ring Loader

Seal into the groove in the piston.

7. Verify that the o-ring is not pinched or twisted.

8. Remove the bi-directional piston seal from the

warm fluid and install it around the end of the

piston, then push it into the piston groove over

the o-ring loader seal (Fig. 343).

Be careful not to cut the OD of this seal.

4. Install the Static Back-Up ring around the groove

in the head (Fig. 341).

Figure 341 DSC-1355

Loading...

Loading...