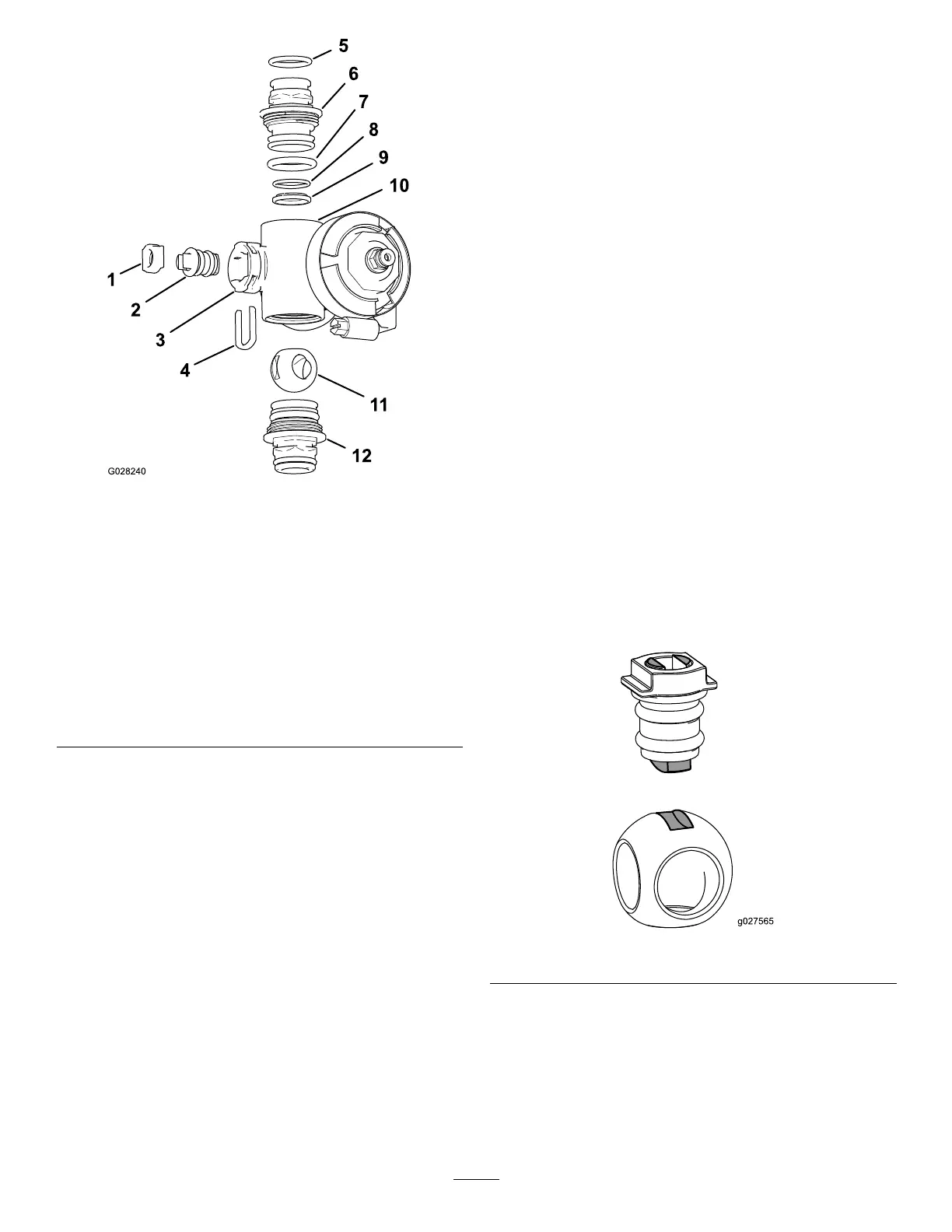

g028240

Figure73

SectionValveManifold

1.Valve-stemseat

7.End-capO-ring(0.796x

0.139inch)

2.Valve-stemassembly

8.BackseatingO-ring(0.676

x0.07inch)

3.Stemport

9.Ballseat

4.Stemretainer10.Manifoldbody

5.OutletttingO-ring(0.737

x0.103inch)

11.Ballvalve

6.Coupling(manifold)12.Couplingassembly

(manifold)

3.Turnthevalvestemsothattheballisinthe

openposition(Figure71A).

Note:Whenthevalvestemisparallelwiththe

valveow,theballslidesout.

4.Removethestemretainerfromtheslotsinthe

stemportinthemanifold(Figure72andFigure

73).

5.Removethestemretainerandvalvestemseat

fromthemanifold(Figure72andFigure73).

6.Reachintothemanifoldbodyandremovethe

valve-stemassembly(Figure72andFigure73).

7.Cleantheinsideofthemanifoldandexterior

oftheballvalve,valve-stemassembly,stem

capture,andendttings.

AssemblingtheManifoldValve

1.Checktheconditionoftheoutlet-ttingO-rings

(section-valvemanifoldonly),end-capO-rings,

backseatingO-rings,ballseatfordamageor

wear(Figure72andFigure73).

Note:ReplaceanydamagedorwornO-rings

orseats.

2.Applygreasetothevalvestemandinsertitinto

thevalve-stemseat(Figure72andFigure73).

3.Installthevalvestemandseatintothemanifold

andsecurethestemandseatwiththestem

retainer(Figure72andFigure73).

4.EnsurethatthebackseatingO-ringandtheball

seatarealignedandseatedintotheend-cap

tting(Figure72andFigure73).

5.Installtheend-cap-ttingassemblyontothe

manifoldbodyuntiltheangeoftheend-cap

ttingtouchesthemanifoldbody(Figure72

andFigure73),thenturntheend-capttingan

additional1/8to1/4turn;torquethettingto225

to282N∙cm(20to25in-lb).

Note:Usecautionsoasnottodamagetheend

ofthetting.

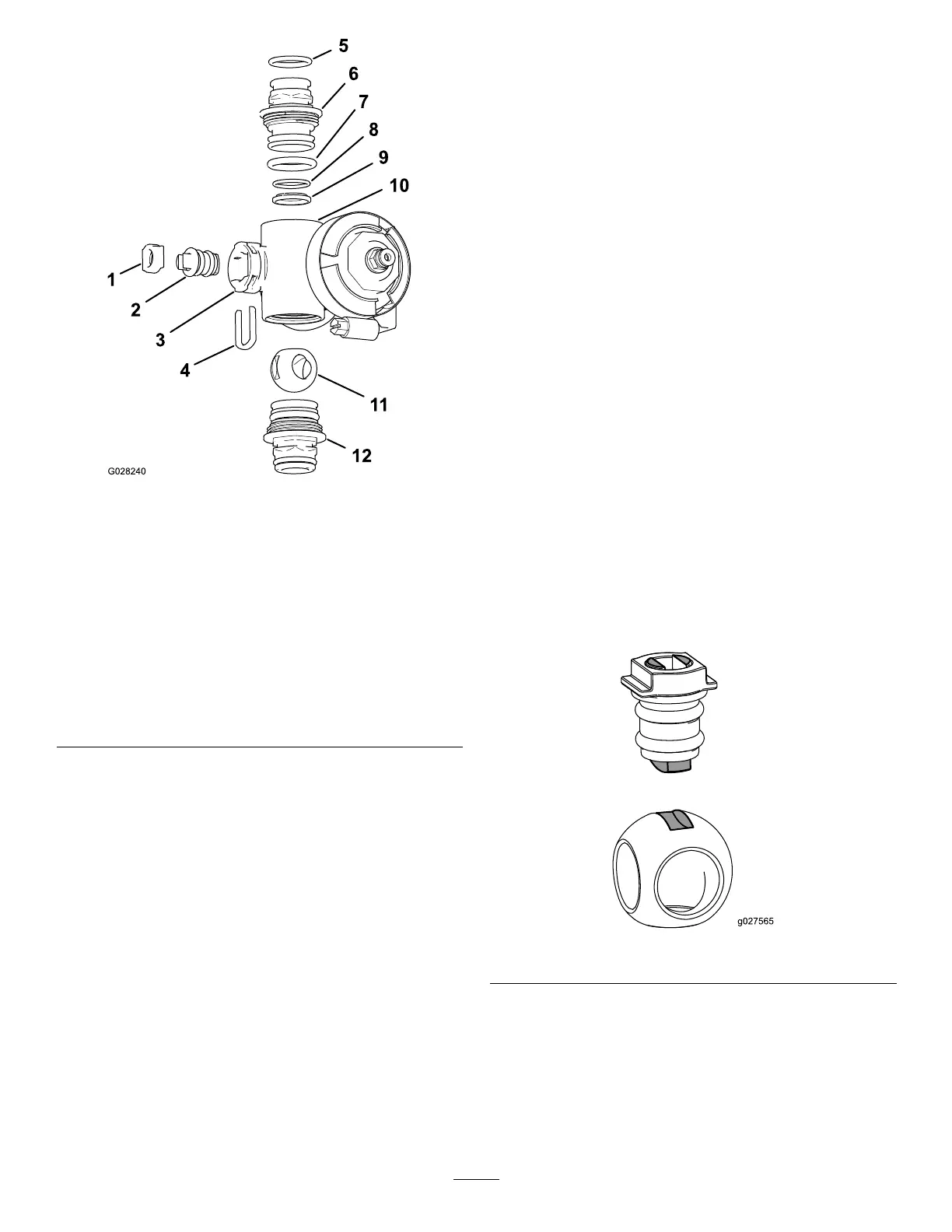

6.Inserttheballintothevalvebody(Figure74).

Note:Thevalvestemshouldtinsidetheball

driveslot.Ifthevalvestemdoesnott,adjust

thepositionoftheball(Figure74).

g027565

Figure74

7.Turnthevalve-stemassemblysothatthevalve

isclosed(Figure71B)

8.Repeatsteps4and5fortheotherend-cap-tting

assembly.

63

Loading...

Loading...