Printed in the Federal Republic of Germany TR-Electronic GmbH 2009, All Rights Reserved

12/13/2018 TR - ECE - BA - DGB - 0070 - 17 Page 71 of 108

2.7 Safety functions of the fail-safe processing unit

The Safety Computer System (SCS), to which the measuring system is connected,

must perform the following safety checks.

So that in the event of an error the correct measures can be taken up, the following

definition is valid:

If no more data are sent by the measuring system, or if the measuring system is in

OFF condition, this is to be interpreted as safe condition.

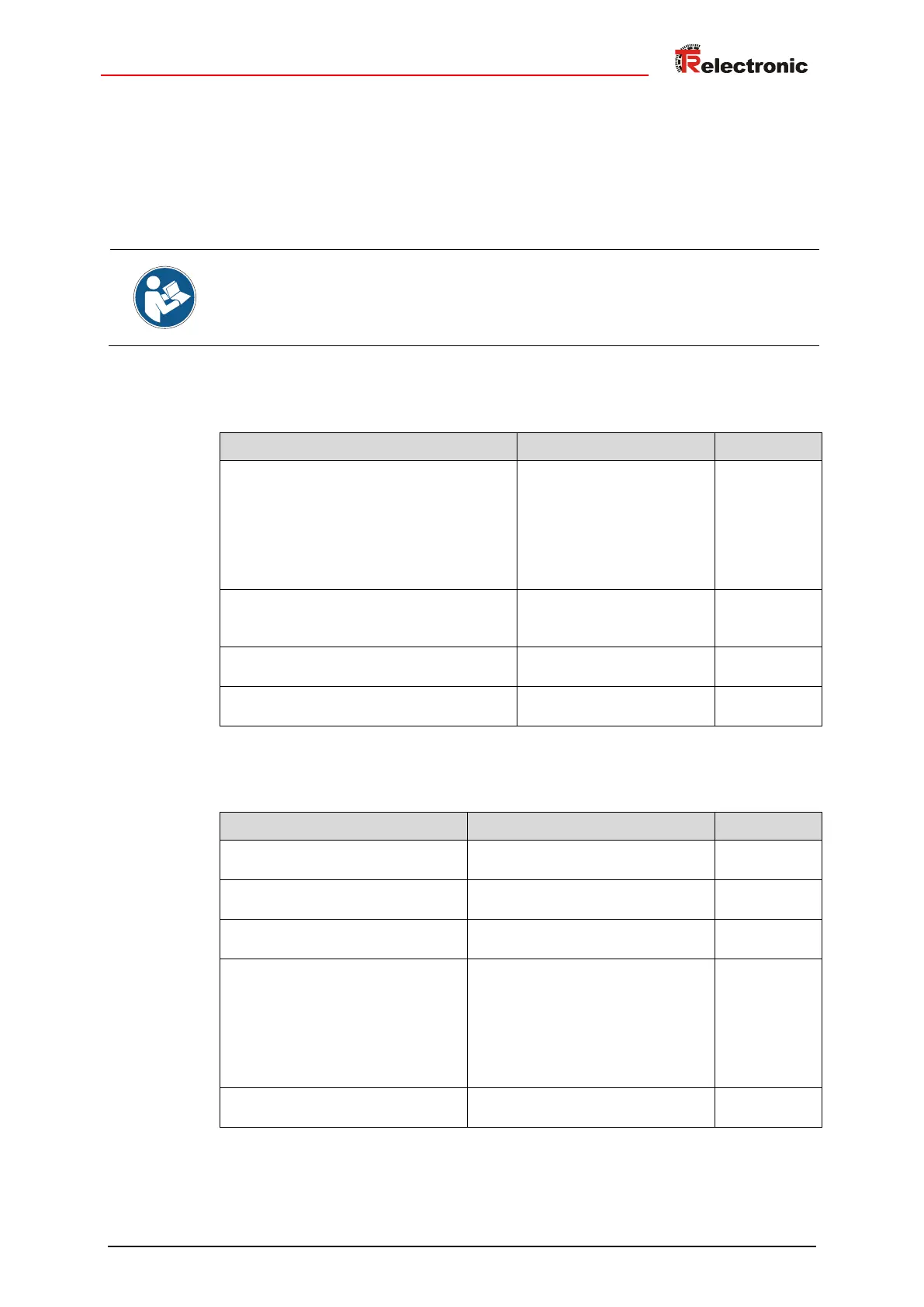

2.7.1 General safety checks

Check by SCS SCS error reaction Necessary?

Comparison of position data of the

master system with position data of the

safety system.

The permissible tolerance window

depends on the SSI behavior and on the

system speed and must be determined by

the plant operator first.

In case of exceeding of

the tolerance window -->

STOP

yes

Cyclical consistency check of the current

master system data to the previous

STOP yes

Travel curve calculation and monitoring

by means of the master system

STOP yes

Data transmission master system and

data transmission safety system blocked

STOP yes

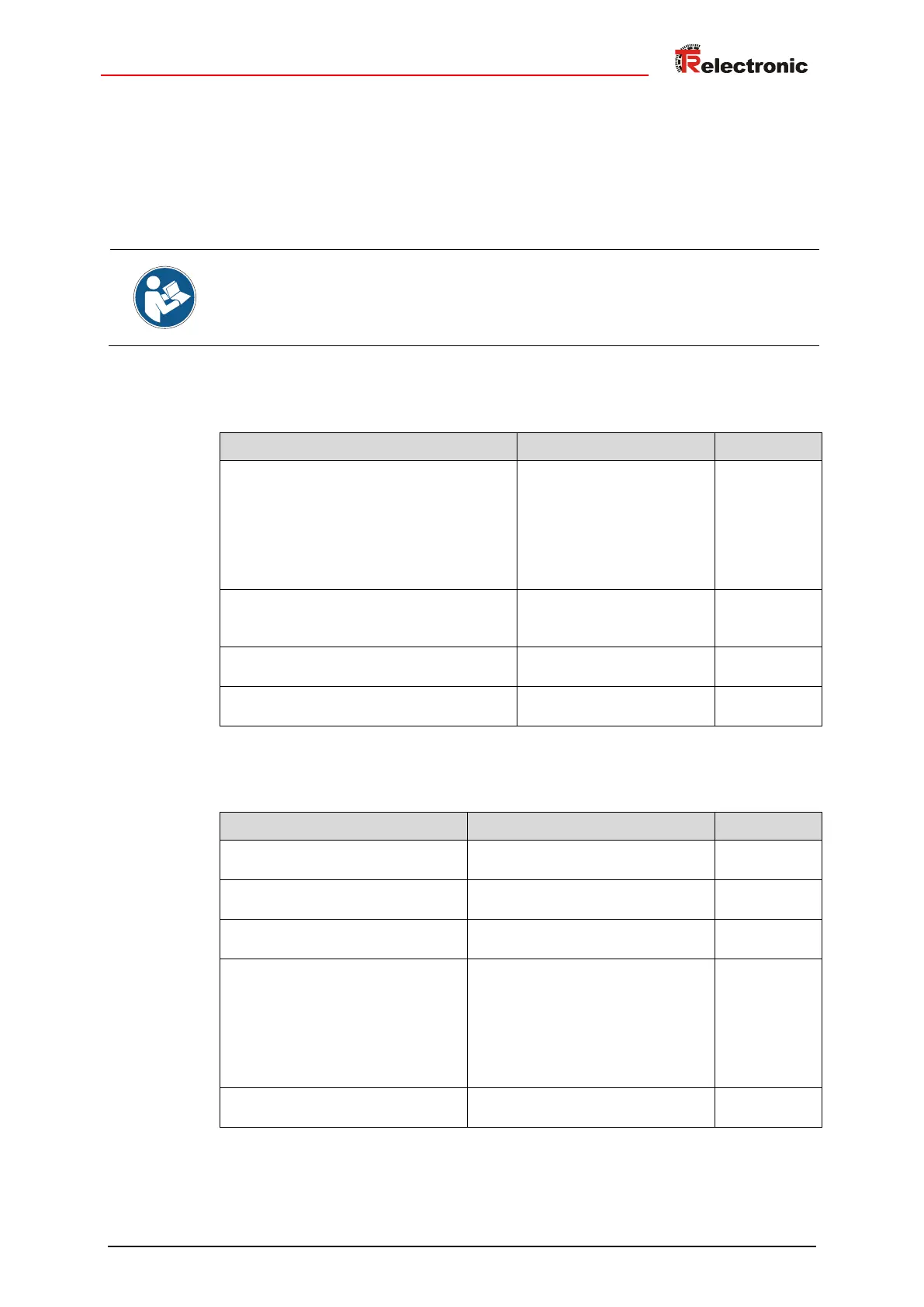

2.7.2 Check of the master system data

Check by SCS SCS error reaction Necessary?

Error bit 1 = 1:

Master system data not safe

Definition in the SCS yes

Error bit 2 = 1:

Safety system data not safe

Definition in the SCS yes

Data transmission master system

blocked

Definition in the SCS yes

Sign of life counter was not

incremented longer than 1 ms

STOP:

If the sign of life counter were

incremented or

the master

system data and safety system

data are within the tolerance

window, after acknowledgment

the travel can be continued.

yes

CRC check master system data

Telegram repetition, two SCS

cycles permitted

yes

Loading...

Loading...