M

ACHINE

P

REPARATION

& O

PERATION

Section

2.5

2-6 SB80 Work Platform - European

2.5 O

PERATION

Before operating work platform ensure that:

• Pre-operation and safety inspection has been com-

pleted, and any discrepancies have been cor-

rected.

• System function inspection has been performed.

• Operator has been thoroughly trained on the oper-

ation of the machine.

• Work area is clear of all obstructions, holes, drop-

offs, or persons in the route of travel.

• Surface is capable of supporting wheel loads.

Refer to Figure 2-2 for control locations.

At any time during operation, press the emergency

stop button to stop all functions in the event of an

emergency.

At any time during operation, press the service horn

button to sound an audible warning in necessary.

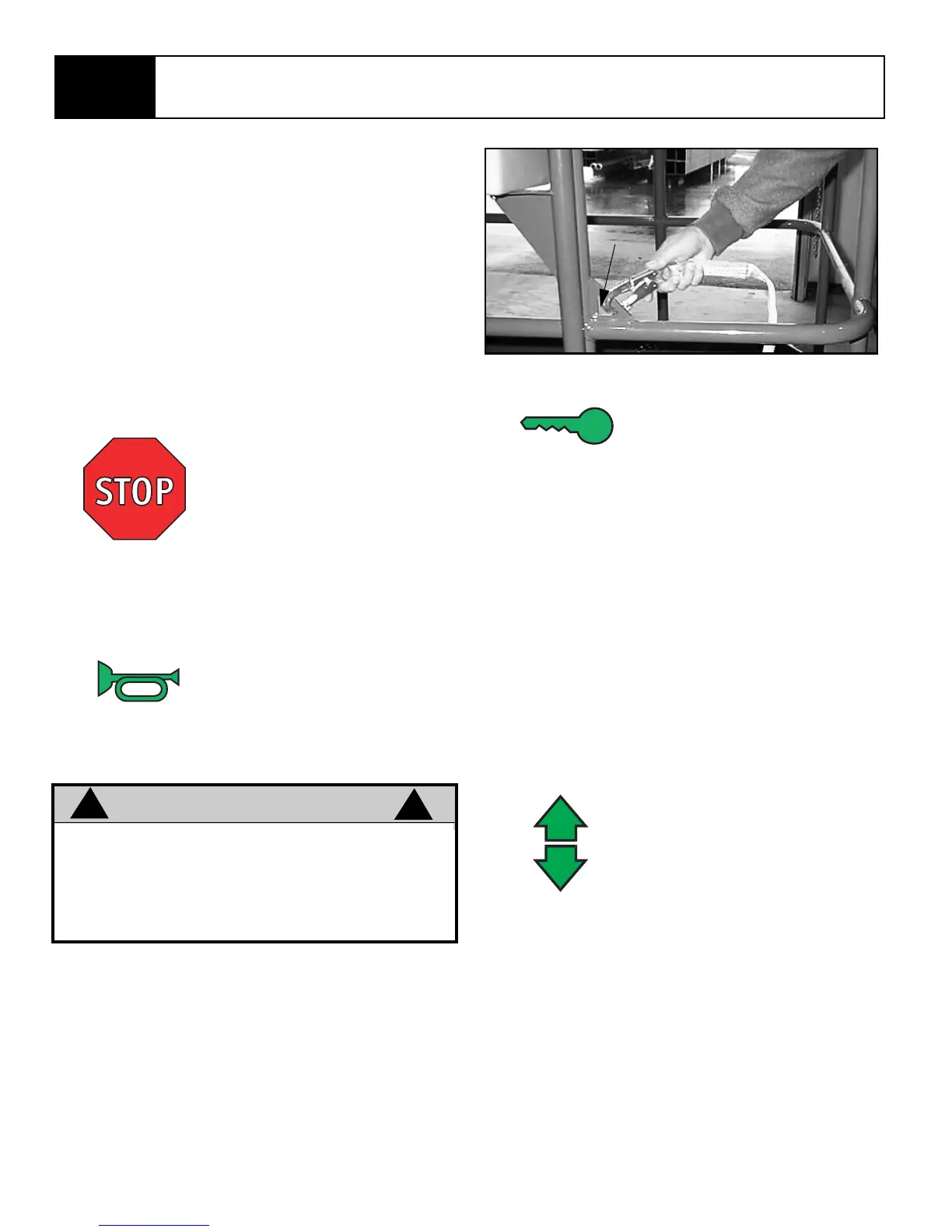

Figure 2-3: Typical Fall Restraint Anchorage Point

From the Lower Controls

1. Turn the chassis key switch to chassis position.

2. Press the start button to crank the engine.

Release when the engine starts.

3. Diesel Engines: When the engine is cold (less

than 15°f); press and hold the glow plug button

for 20 seconds prior to starting.

From the platform controls

1. Turn the chassis key switch to platform controls.

2. Turn the platform rotary switch fully clockwise to

crank the engine. Release when engine starts.

3. Diesel Engines: When the engine is cold (less

than 15°f); press and hold the glow plug button

for 20 seconds prior to starting.

With Boom Lowered

1. Turn chassis key switch to platform, and pull out

the chassis emergency stop switch.

2. Mount the platform and close sliding rail.

3. Attach approved fall restraint to designated plat-

form anchorage point. Attach only one fall

restraint to each point.

4. Start engine.

WARNING

!

!

ALWAYS wear an approved fall restraint prop-

erly attached to designated platform anchorage

point when driving or operating the machine

(Figure 2-3).

Attach only one restraint to each anchorage

point.

Emergency Stop

Service Horn

Starting the Engine

Driving

Loading...

Loading...