SB80 Work Platform - European 3-15

M

AINTENANCE

Section

3.14

5. Remove primary sun gear (24) from end of input

shaft (2).

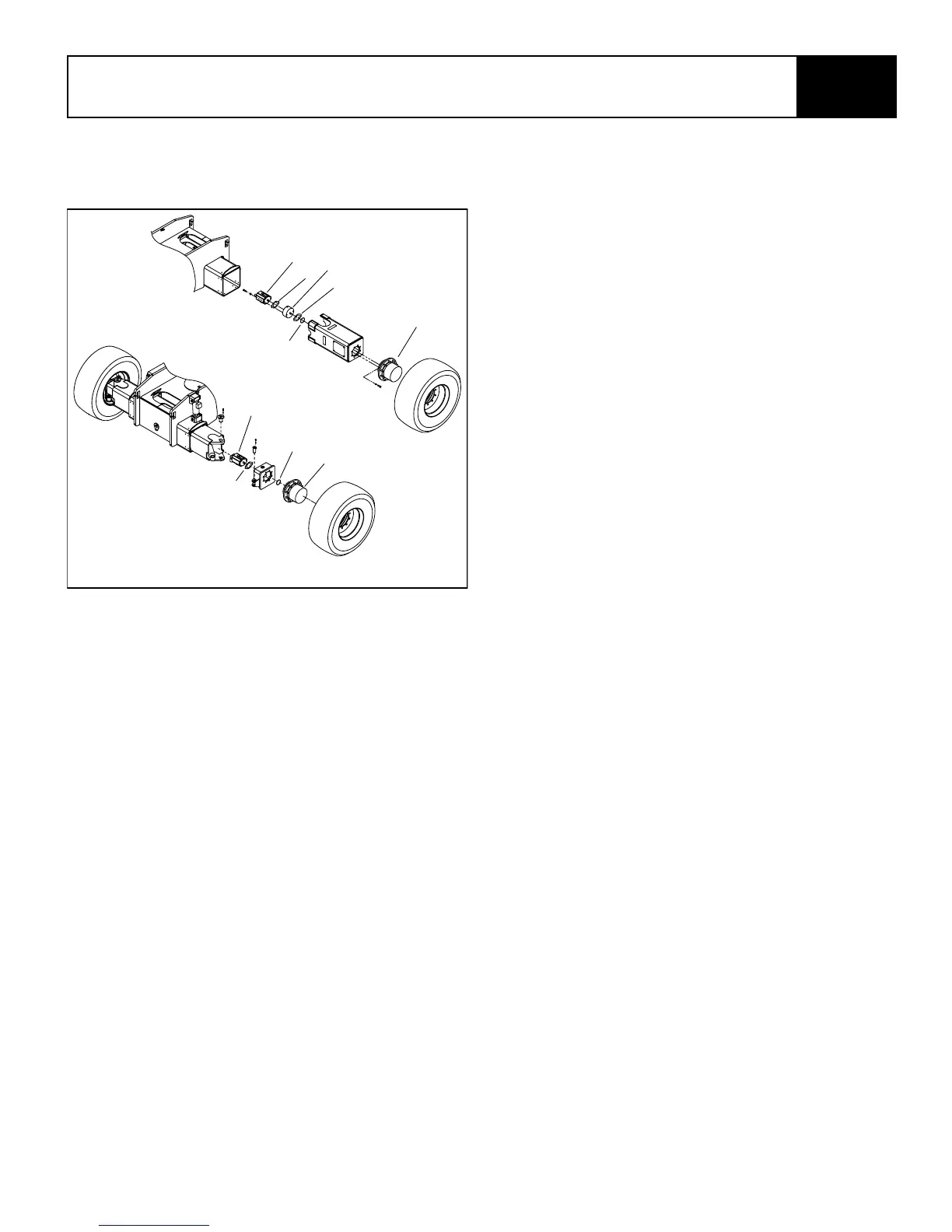

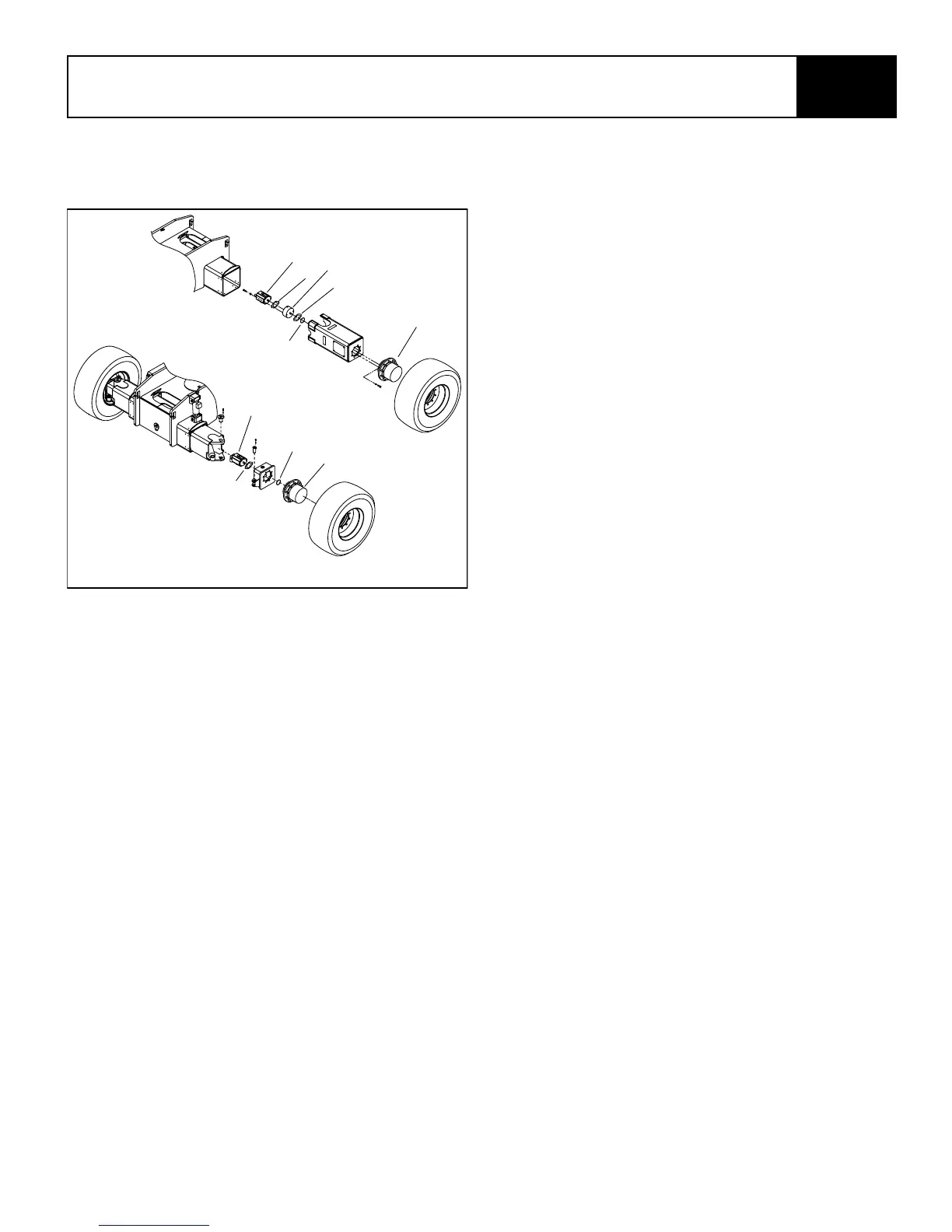

Figure 3-15: Torque Hub Assembly

6. Remove the primary carrier assembly (22).

7. Remove the secondary carrier assembly (21).

8. Remove the input shaft (2) from spindle (3).

Remove the retaining rings (17), washers (18),

and disengage spring (19) from input shaft (2)

only if replacement is required.

9. One tab of lock washer (15) will be engaged in

slot of bearing nut (16); bend back to release.

Remove the bearing nut (16), lock washer (15)

and thrust washer (14).

NOTE: A special locknut wrench is required for

the removal of the bearing locknut. The Bearing

Locknut Tool, Bearing Cone Driver and Spin-

dle/Shaft Drive Tool are included in Service Kit,

part number 100254-020.

10. Bolt Spindle Drive Tool, (Service Kit #100254-

020), to ring gear (20). Grade 8 bolts should be

used. Drive spindle (3) from hub (11) by turning

center bolt of Spindle Drive Tool. Care should be

taken to avoid damaging splines and threads on

spindle.

NOTE: Bearing cone (13) has been designed with

a press fit with respect to spindle (3). Consider-

able force will be required to remove cone from

spindle.

11. Remove Spindle Drive Tool from ring gear (20).

12. Remove the eighteen bolts (9) and washers (10)

from hub (11) and remove ring gear (20). It may

be necessary to strike ring gear (20) with a rub-

ber mallet to loosen from hub (11).

13. Remove the boot seal (4) and oil seal (5) and

bearing cones (6 & 13) from hub (11). Inspect

bearing cups (7 & 12) in position and remove only

if replacement is required.

Assembly of Torque Hub

1. Press new bearing cups (7 & 12) in each side of

the hub (11). It is recommended that bearing

cups (7 & 12) and cones (6 & 13) be replaced in

sets.

2. Assemble bearing cone (6) into cup (7) at seal

end of hub (11) and press a new seal (5) into hub

(11). Install boot seal (4) on hub (11) if unit is so

equipped.

3. Position spindle (3) upright on bench. Lubricate

lips of seal (5) and lower hub (11) onto spindle

(3). Hub (11) should be centered as it is lowered

over spindle (3) to prevent seal damage.

4. Assemble bearing cone (13) over spindle (3).

Press bearing cone (13) over spindle bearing

journal using press and cylindrical Bearing Cone

Driver (Service Kit #100254-020). Press bearing

cone (13) down until rollers just touch cup (12).

Take care to avoid pressing cone (13) to far.

NOTE: If a press is not available, place Bearing

Cone Driver tool over splined end of spindle (3)

on the edge of bearing cone (13) and drive into

place with hammer or mallet. If this method is

used, care must be taken to avoid damage to

bearing cone and spindle.

5. Install thrust washer (14) with tab in keyway of

spindle and bearing nut (16). DO NOT install lock

washer (15) at this time.

6. Clean mating surfaces and apply a bead of sili-

cone sealant to face of hub (11) that mates with

ring gear (20). See instructions on sealant pack-

age. Hub (11) is attached to ring gear (20) with 18

3/8-24 grade 8 hex head cap screws (9) and flat

washers (10). Torque cap screws to 70-81 Nm

(52-50 lb.-ft.).

7. Place Spindle Drive Tool (Service Kit #100254-

020), over spindle (3) and bolt or pin to ring gear

(20). Make sure center bolt of Drive Tool is not

touching spindle and is prevented from rotating

by jam nuts provided on tool.

Rear

Front

1

2

2

3

4

1

2

5

5

4

1. Motor

2. Gasket

3. Brake

4. Torque Hub

5. O-Ring

Loading...

Loading...