SB80 Work Platform - European 3-27

M

AINTENANCE

Section

3.19

Test the actuator for proper operation and leakage

prior to securing the endcap with set screws. Mark

the relative position of endcap and housing and

check the marks periodically during the tests below

to ensure that the endcap does not back out. Apply

pressure to the actuator ports and check breakaway.

The breakaway should be about 13,8 bar (200 PSI).

Alternately apply pressure to port on the opposite

side of the piston and check for axial movement. The

axial movement should not exceed ,5 mm (.020”). If

the axial movement is excessive retighten the end

cap. Apply 206,8 bar (3000 PSI) pressure to one port

until piston bottoms out and the actuator rotation

stops. Remove non-pressurized hydraulic line and

check for internal and external leakage. Repeat leak-

age test on opposite actuator port.

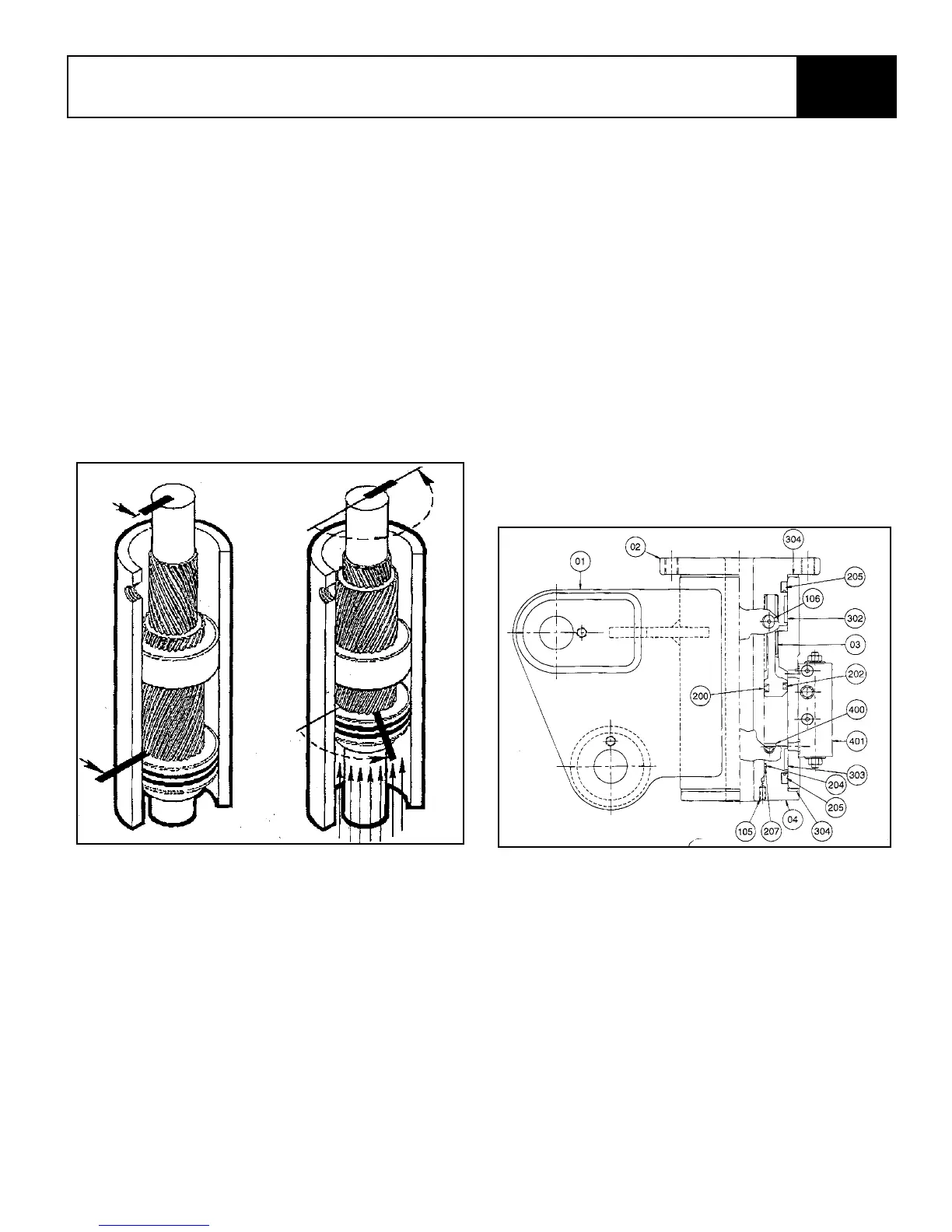

Figure 3-33: Rotary Actuator

Testing and Storage

All HP-9K actuators are tested and operated through

at least twenty-five (25) full cycles at 158,5 bar (2300

PSI) and proof tested at 310,3 bar (4500 PSI) for

structural integrity. Both tests are conducted through

the actuator with the valve installed.

Helac Corporation actuators are normally shipped

filled with petroleum base hydraulic oil. The ports are

plugged with the proper high strength steel plugs to

prevent leakage during shipment.

Hydraulic Line Attachment

The hydraulic lines from the control valve to the actu-

ator should be as short as possible. If the lines hold

more oil than the actuator displaces, the oil is cycled

back and forth, and not allowed to flow to tank for fil-

tering and cooling, resulting in accelerated actuator

wear.

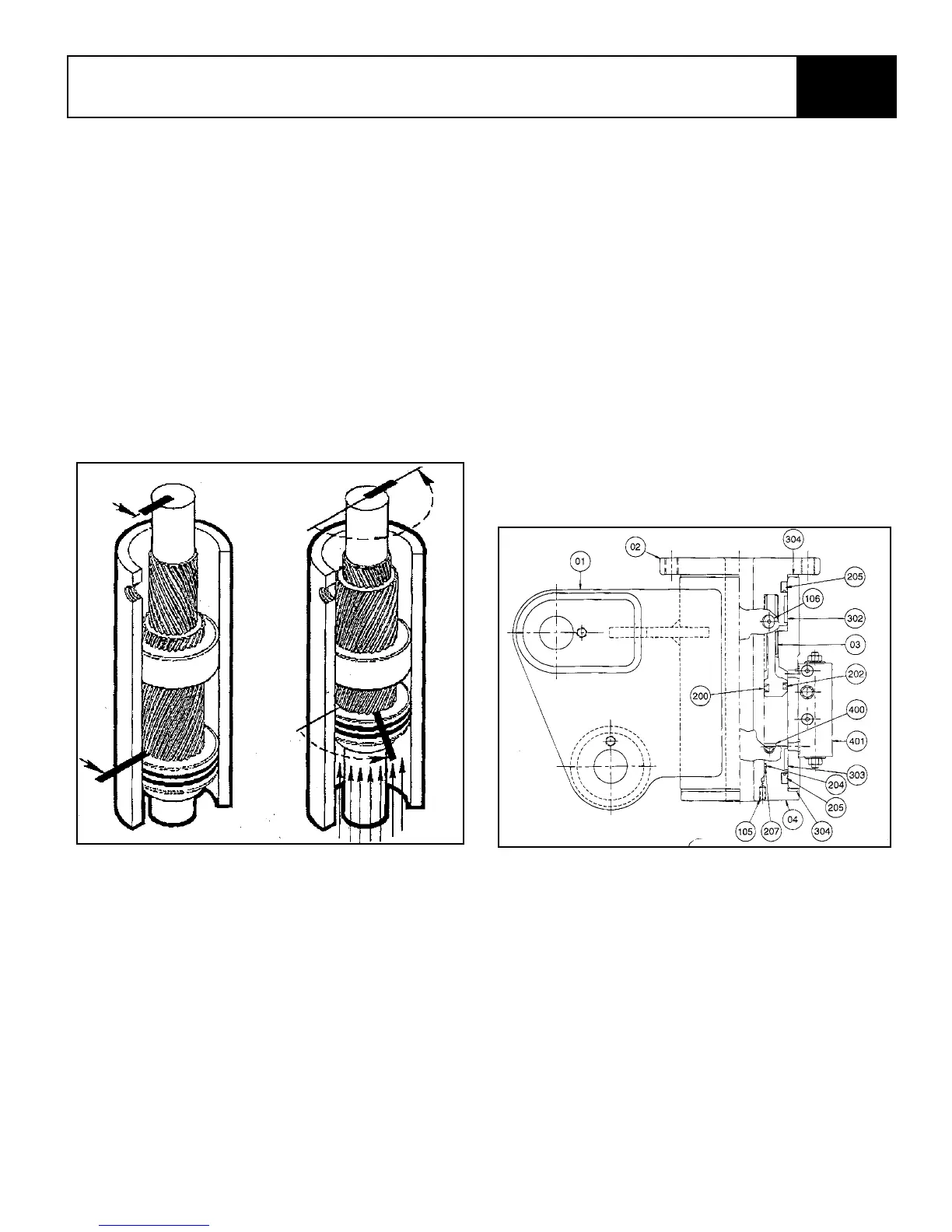

Figure 3-34: Cage Rotator

Install set screws (105) and stake to insure they will

not back out during actuator operation.

Bars indicate starting

positions of piston and

shaft. Arrows indicate

direction they will

rotate. The housing

with integral ring

gear remains

stationary.

As fluid pressure is

applied, the piston is

displaced axially while

the helical gearing

causes the piston and

shaft to rotate simulta-

neously. The double

helix design com-

pounds rotation: shaft

rotation is about twice

that of the piston.

Loading...

Loading...