3-20 SB80 Work Platform - European

M

AINTENANCE

Section

3.17

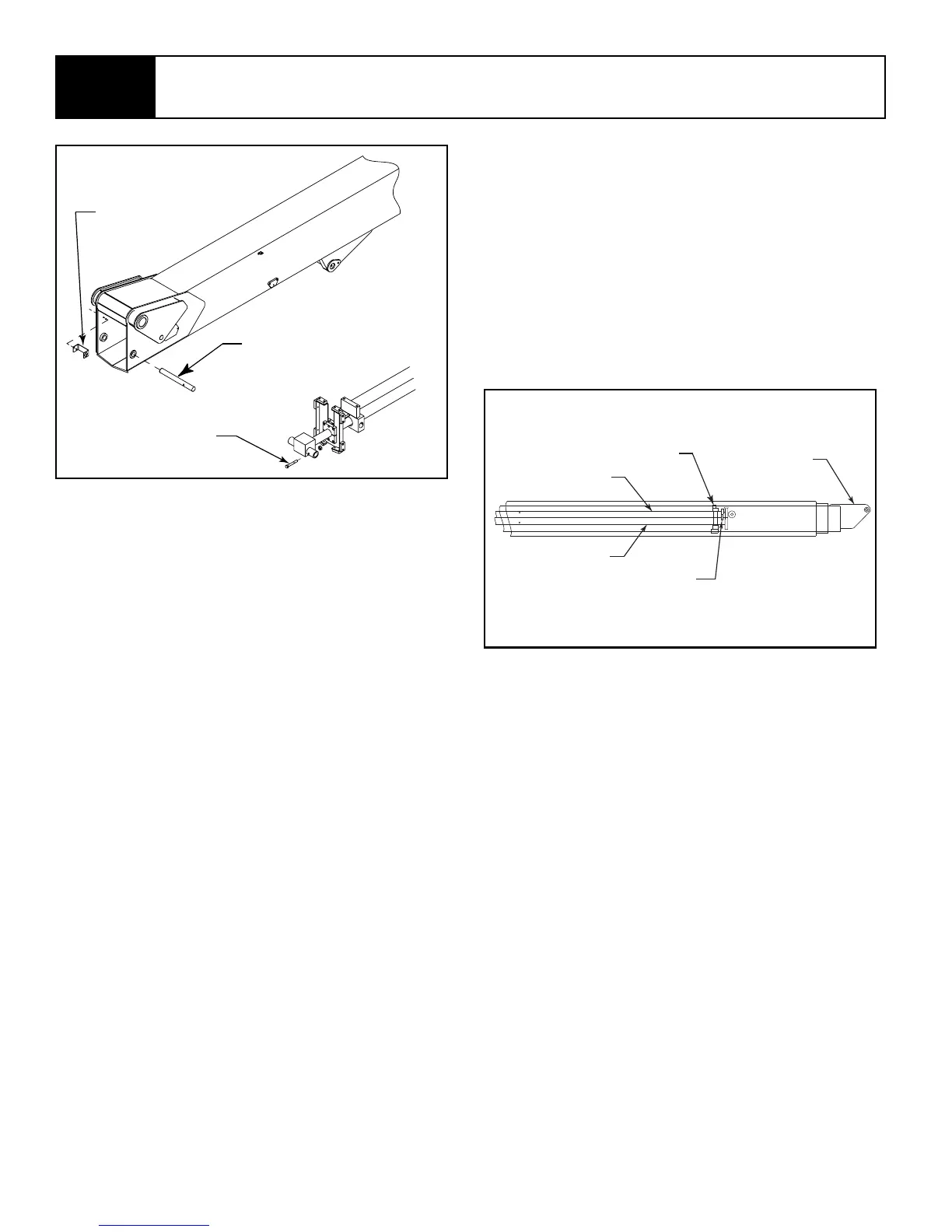

Figure 3-22: Remove Rear Pin Cap Screw

17. Remove and cap hoses from the front of the cyl-

inder.

18. Remove the Interlock Switch Bracket and move it

out of the way.

19. Remove the pin at the front of the cylinder.

20. Cylinder will now slide out the front of the boom.

IMPORTANT: Use a fork lift or overhead hoist to

support the cylinder.

3.17 I

NSTALLING

E

XTEND

C

YLINDER

Installation of Extend cylinder is reverse of removal.

IMPORTANT: Reinstall slide pads, spacers and

other items which were removed when cylinder

was removed.

IMPORTANT: After cylinder is installed, extend tip

boom until Four Tip Boom threaded inserts are

exposed. Reinstall 3/8 cap screws. Rear/upper

Rod Slide must be positioned to the rear of rear

Rod Slide Weldment when cylinder is replaced.

Tighten 1/4 cap screws which secure Rod Slide

to hold front it in place.

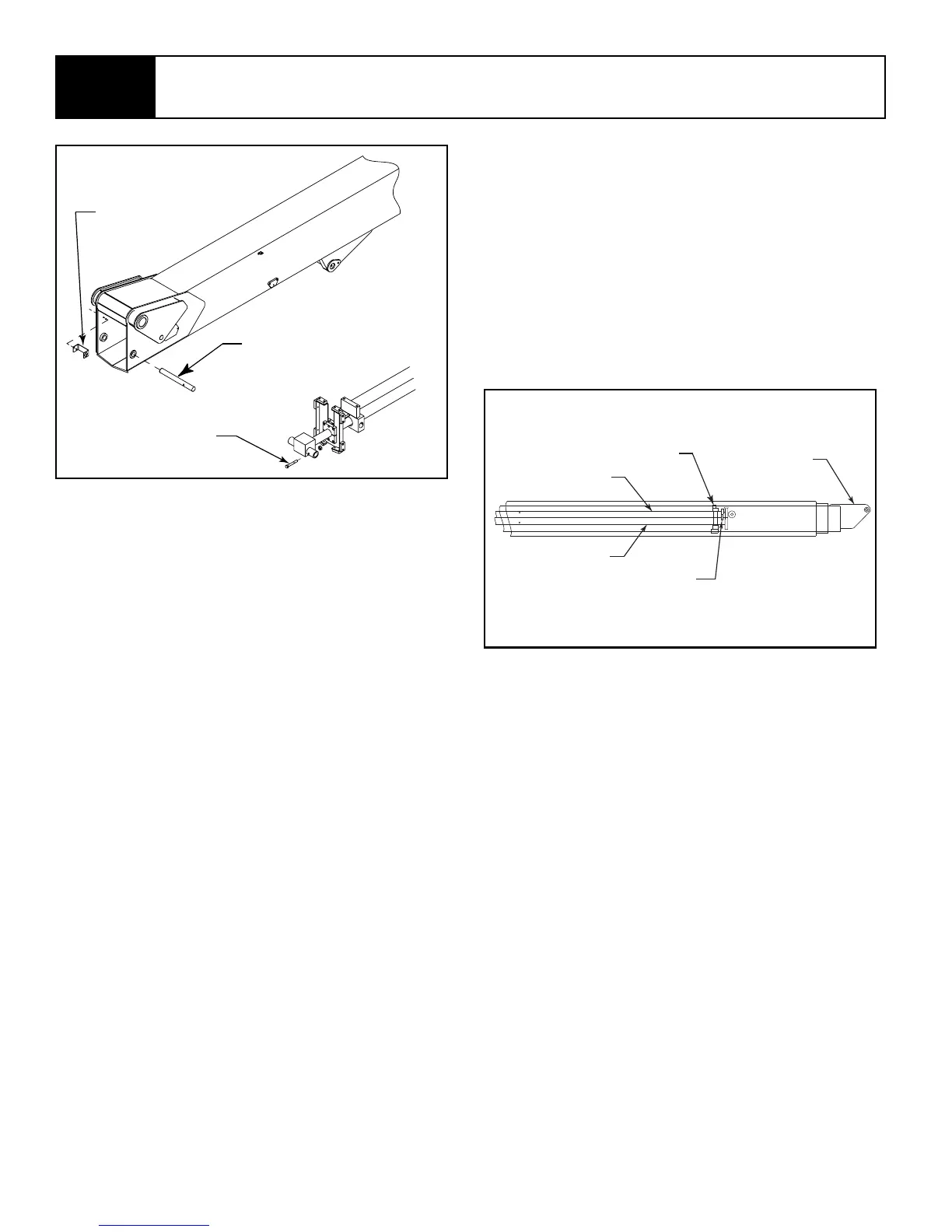

Figure 3-23: Positioning Tip Boom Rod Slide

Weldment

Cycle extend cylinder several times to remove air

from the hydraulic system. Replenish hydraulic fluid if

necessary.

Slowly cycle extend cylinder to check for proper oper-

ation and check for leaks.

Interlock Switch Bracket

Front Cylinder Pin

Remove Cap Screw

Tip Boom

Upper Cylinder

Lower Cylinder

Tip Boom Rod Slide Weldment

Tip Boom Rod Slide

Loading...

Loading...