723

Model Code Page

42. Gearbox

1. 8. 1998

6000--8750 424 1

8. 11. 1990

1. Reconditioning differential (Op. no.

424)

Note! If reconditioning the differential only, then remove:

--- P T O u n i t (see Op. no. 462 1A)

--- final drives/brake housings

--- d i f f e r en t ia l ( see Op. no. 423 2A)

Note! For detaching the brake housings, raise the cab or split

the tractor between the gearbox and fuel tank according to

Op. 423 1A.

A. Changing the differential side bevel

gear bearings and the differential lock

discs

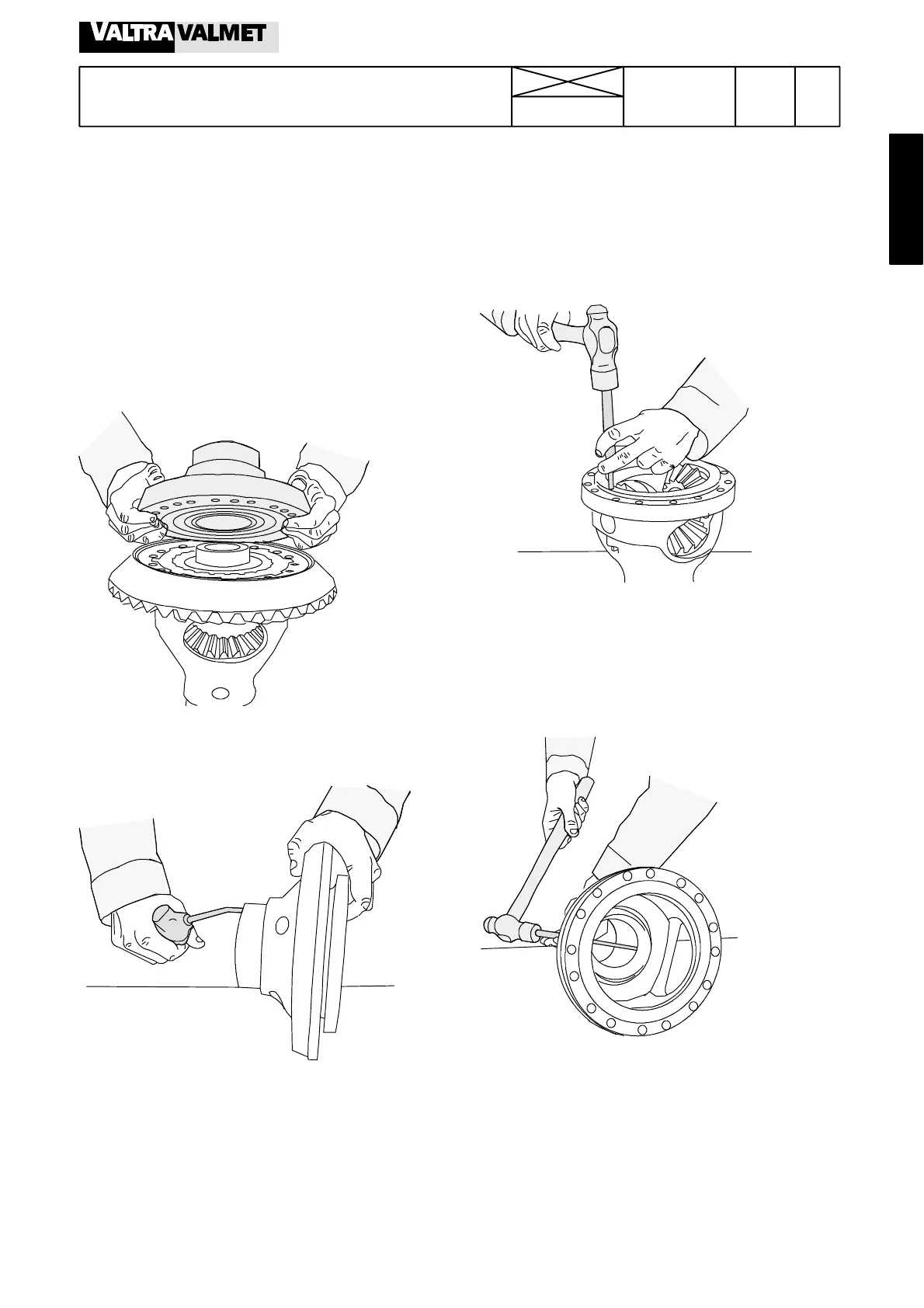

1. Remove the crown wheel attaching screws and remove the

differential cover.

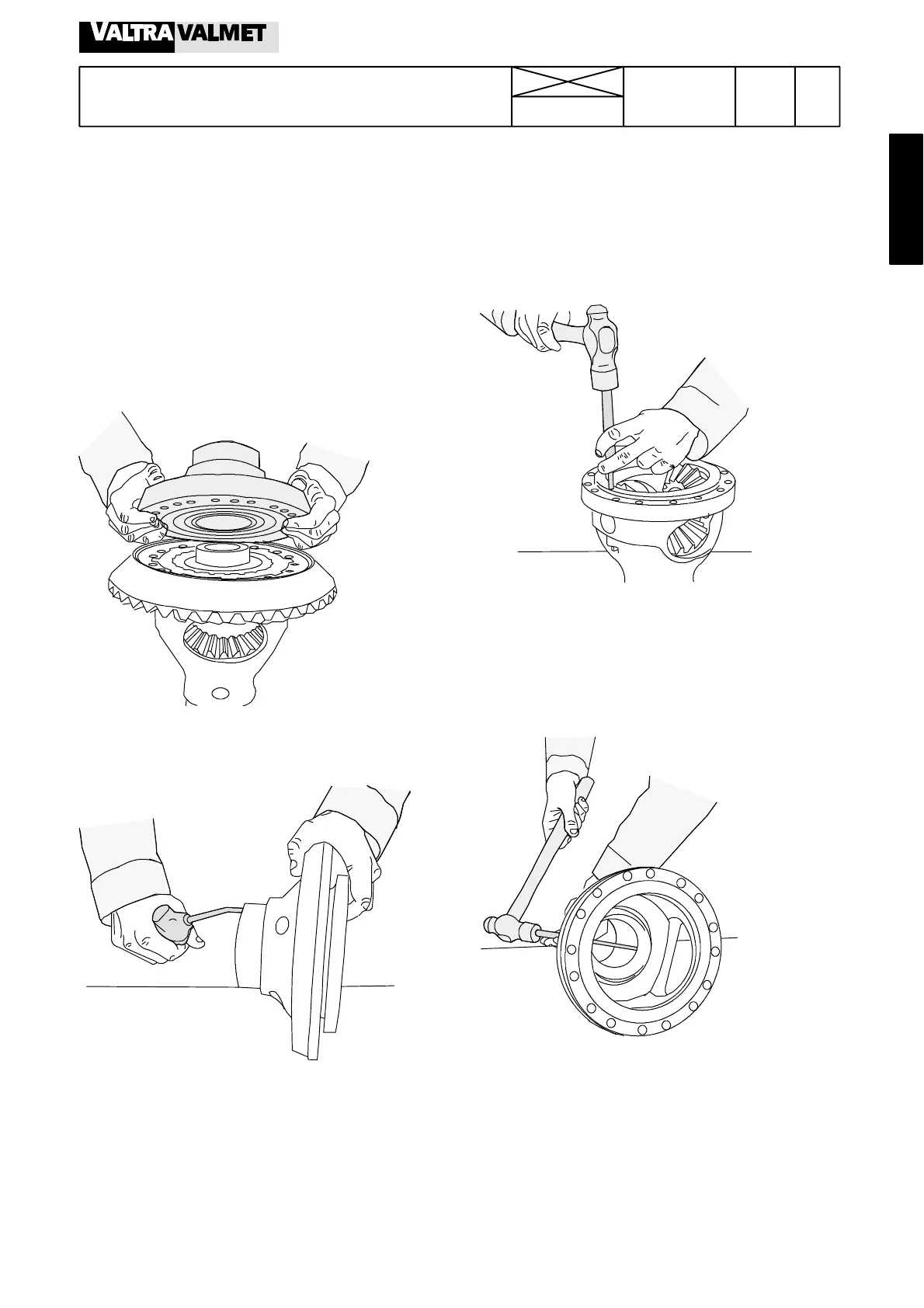

2. Press the piston forthe differential lock out of the casing half

using compressed air but be careful. Change the o---rings on

the piston.

3. Change the bearing for the differential side gear. Remove

the bearing using a drift and fit the new bearing using ETV

891870.

4. Lubricatethe o---ringson the pistonand pushthe pistoninto

place.

5. Lift off the crown wheel. Remove the friction and steel discs

and lift out the differential side gear.

6. Drive out the tubular pin (8 mm) locking the differential

pinion shaft and tap out the shaft. Lift out the differentialpinion

and the right differential side gear.

Note! In the tractors which have higher engine outputs there

are four differential pinions in the differential, at which time the

short pinion shafts have been secured with tensio n pins.

7. Remove the right side differential side gear using a hammer

and a drift. Fit a new bearing using ETV 891870.

8. Lubricatethe bearing and fit the right---hand sidedifferential

side gear in position. Lubricate the differential pinions and

place them in the differential casing. Drive the shaft for the dif-

ferential pinions into place.

9. Fix the shaft in position with the tubular pin.

Note! On models 6600---6900 and 8050---8750 the shorter

pinion shafts are locked with two tension pins.

Loading...

Loading...