simple repairs if necessary. Check all cooling lines and capillary lines for vibration and reinforce if necessary.

Carefully inspect all refrigeration line accessories for oil traces to determine the location of the leak.

5) Compressor

The compressor failures generally fall into the following two categories:

⚫ Motor failure (such as coil burnout, insulation damage, short circuit between turns, etc.).

⚫ Mechanical failures (such as compression failure, pressure relief valve failure, thermal disk failure, etc.).

If the operating pressure cannot be established, the compressor has failed. The suction pressure and the exhaust

pressure are maintained in equilibrium after starting, and after the cause of the reverse running is excluded, the

compressor failure can be determined.

The air conditioner group control system has strong alarm function and protection function to ensure the safe

operation of the compressor. During periodic maintenance and inspection, maintenance personnel should record high

and low pressure values and confirm the cause of fault alarm protection in a timely manner.

Notices

1. Avoid direct contact of human skin with residual gases and lubricants in the compressor system. Wear long rubber gloves when

handling contaminated parts.

2. The residual refrigerant in the system should be recovered by standard recovery equipment before maintenance. Discharge of

refrigerant into the air can cause environmental pollution. Refrigerant emissions must comply with national and local laws and

regulations.

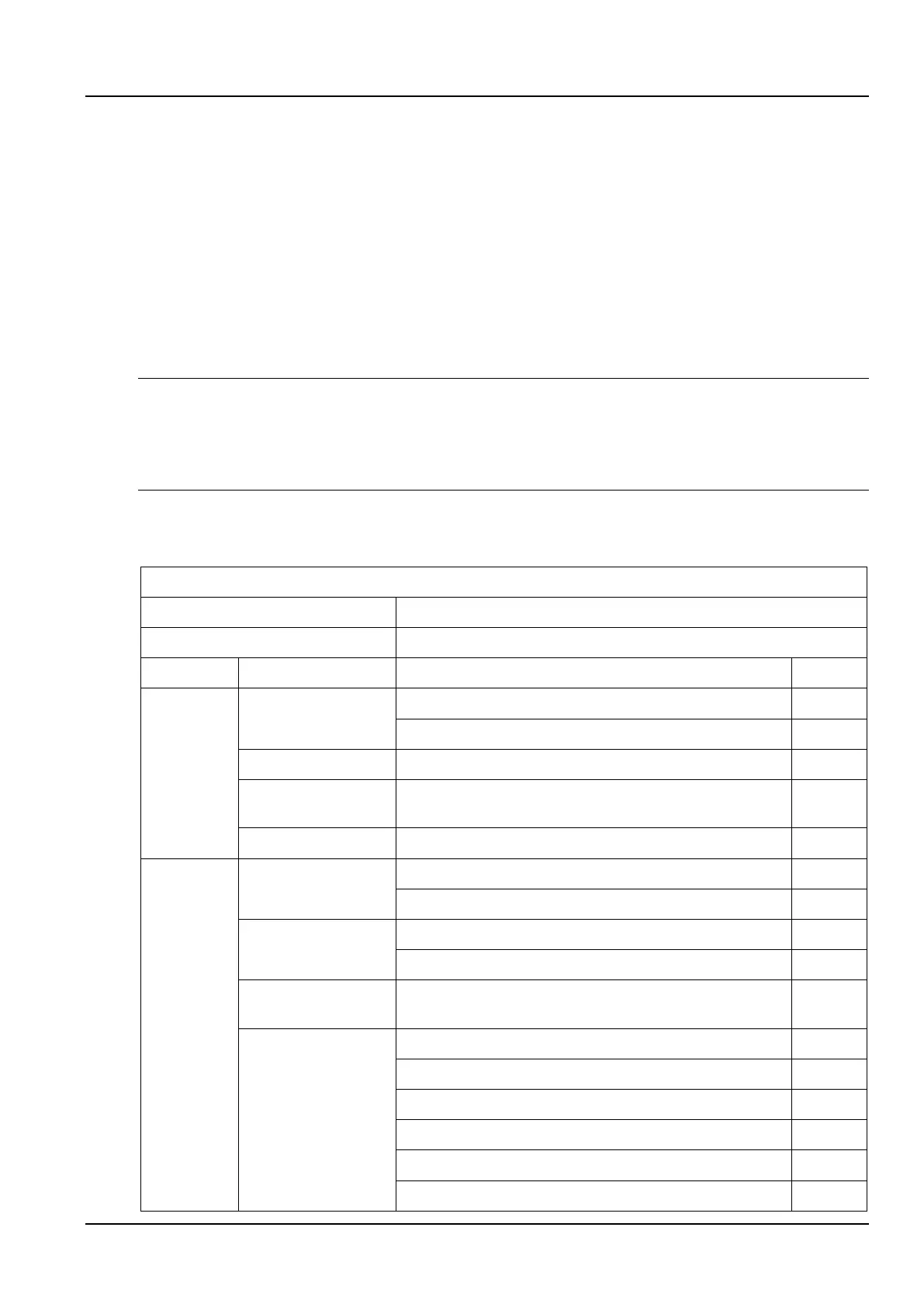

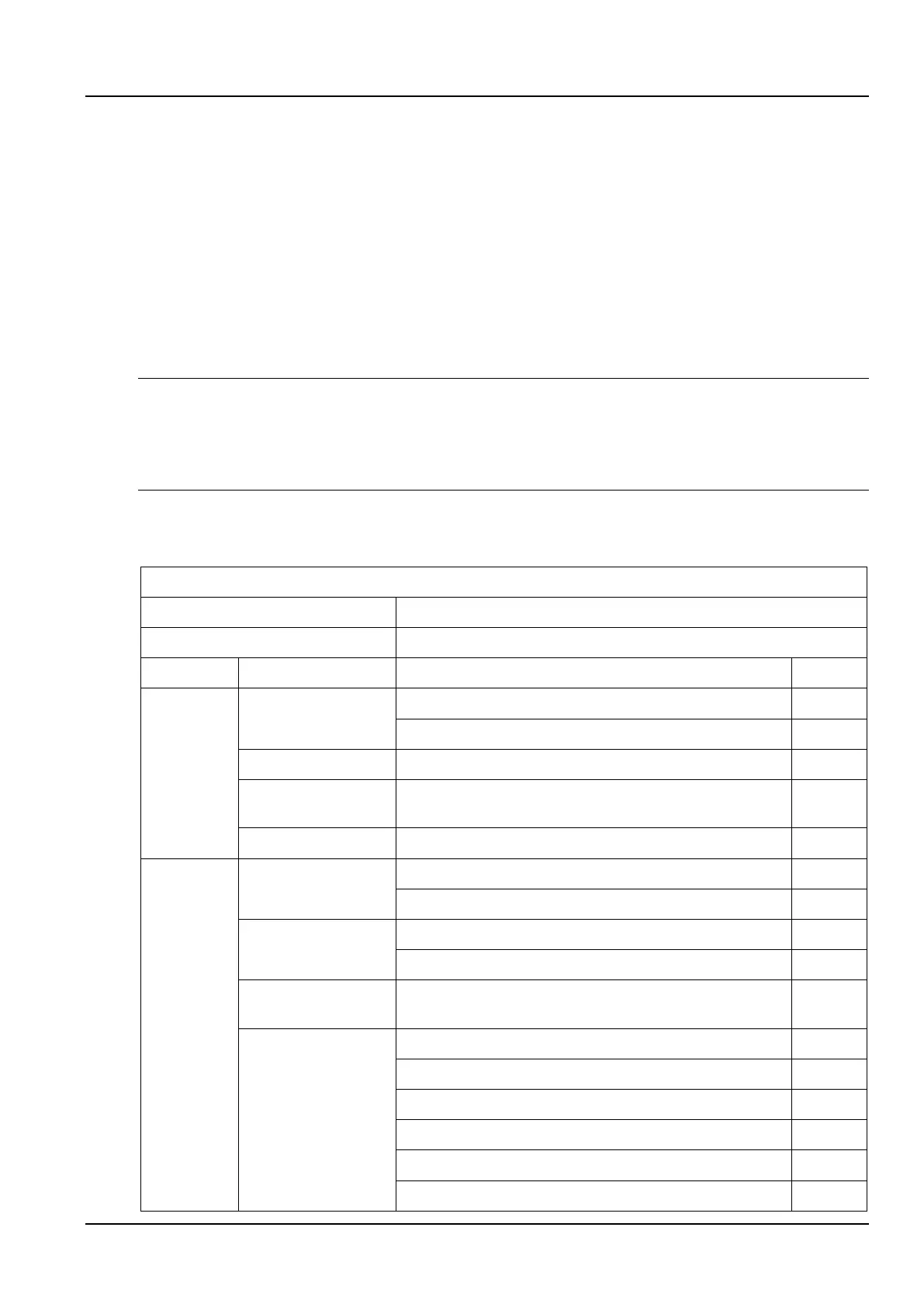

3. Air conditioner system inspection and maintenance checklist

Table 4-3 AC Maintenance Checklist

Loading...

Loading...