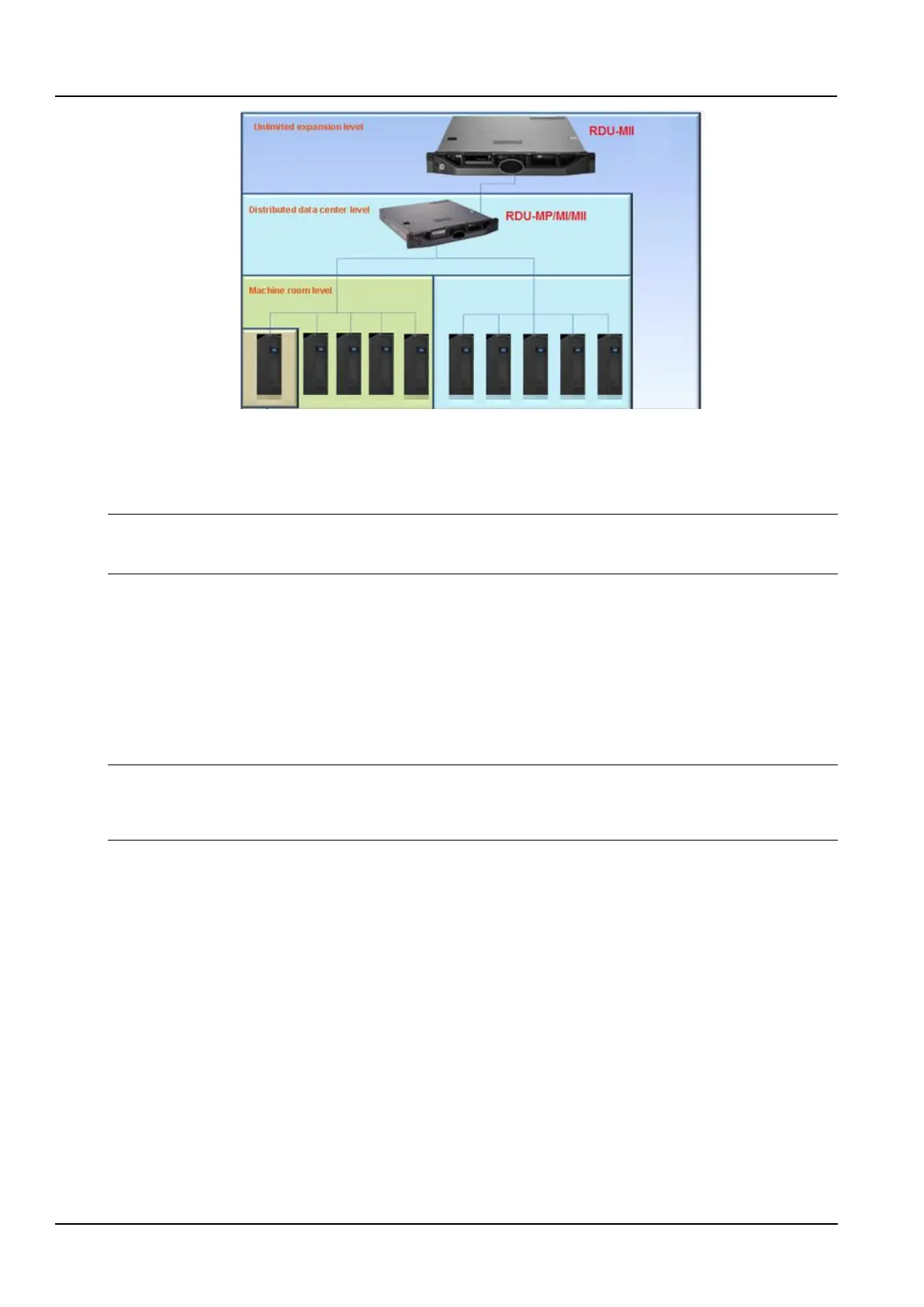

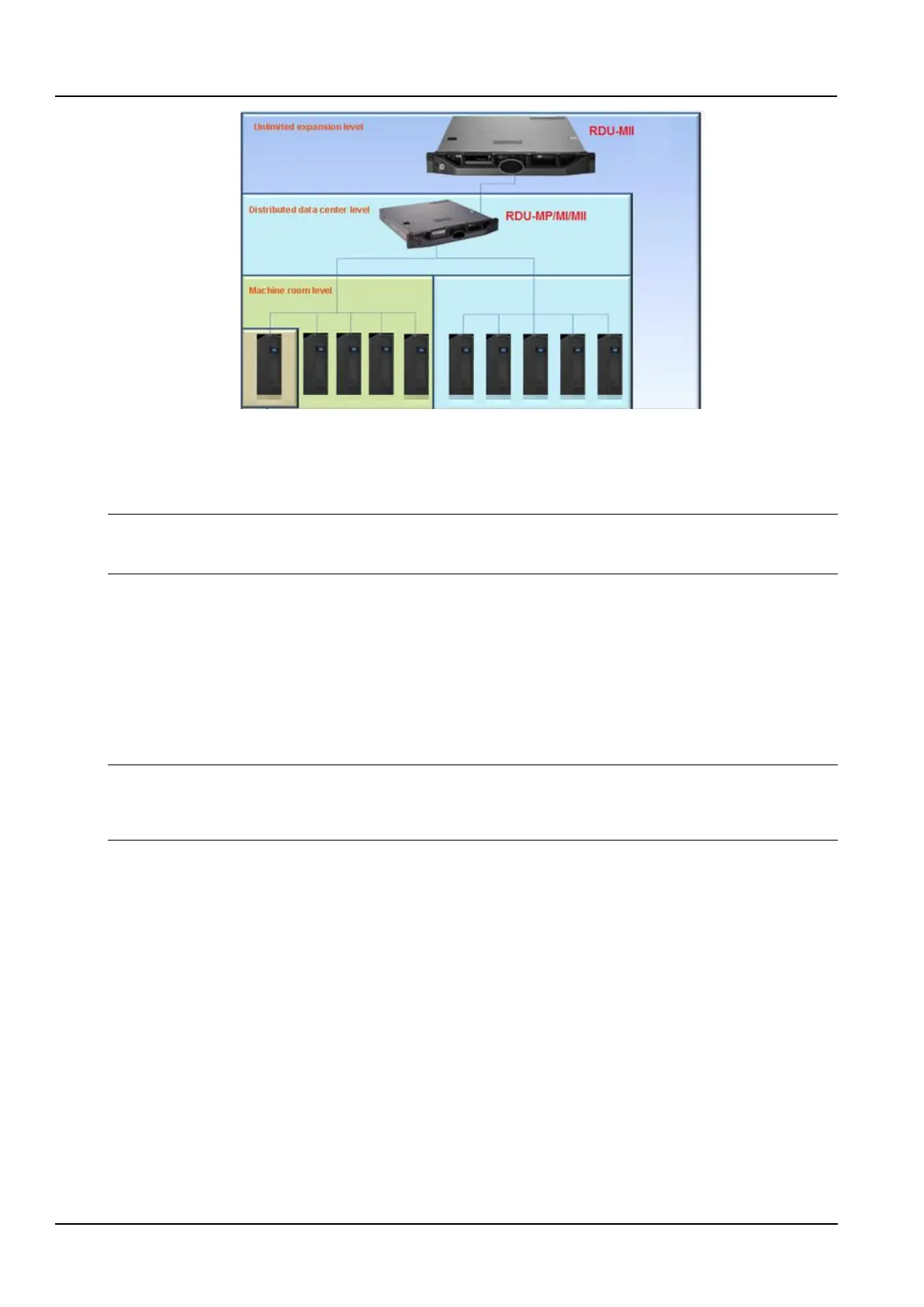

Figure 4-1 Network Topology FIG SmartCabinet2-E

4.3.2 Air Conditioner System Maintenance

The air conditioner system maintenance mainly includes two aspects: electrical system inspection and cooling system

inspection.

Notices

When maintaining the device, the MCB should be disconnected and the power supply should be cut unless the power is required

for the commissioning project.

1. Electrical system inspection

The control panel and temperature sensor should be visually inspected every six months to determine if the

electrical connections are loose or not.

Check the maintenance one by one as follows:

1) Perform electrical insulation test of the whole unit, find unqualified contacts and handle them.

2) Tighten each electrical contact.

3) Clean dust off electrical and control components with a brush or dry compressed air.

Notices

All boards are forbidden to be plugged and unplugged with power on. The hot plug can generate a large amount of instantaneous

current, which may cause irreparable damage to the circuit. All maintenance for the control board must be performed after the

microprocessor controller is powered down.

2. Cooling system inspection

1) Fan

The running characteristics of the fan kit are continuous operation for 24 hours. Any abnormal airflow blocking factor

should be eliminated in time to avoid the damage of the cooling system and other system components.

2) Drainage pipe

In order to ensure the normal operation of the drain pipe, the water tray should be tested regularly. Make sure there

are no fine debris or leaks in the drainage pipe.

3) Cooling components

The cooling system components should be fully tested every month to discover abnormal operation phenomena in

time. The cooling line should be securely fastened and cannot vibrate with the frame of the wall, floor or equipment.

Check the cooling line for wear every six months.

4) Condenser

When the condenser air flow is obstructed, use a compressed air or fin cleaning agent (weak alkaline) to clean the

condenser and remove dust and debris that obstruct the air flow. When cleaning the fins with compressed air, the

direction of purging should be the direction of reverse air flow. Inspect the fins for rewinding or damage and perform

Loading...

Loading...