7-14 BA 357-00 * 3.0 * 35700_07_Wartung.fm

7 Maintenance

7.3 Fluids and lubricants

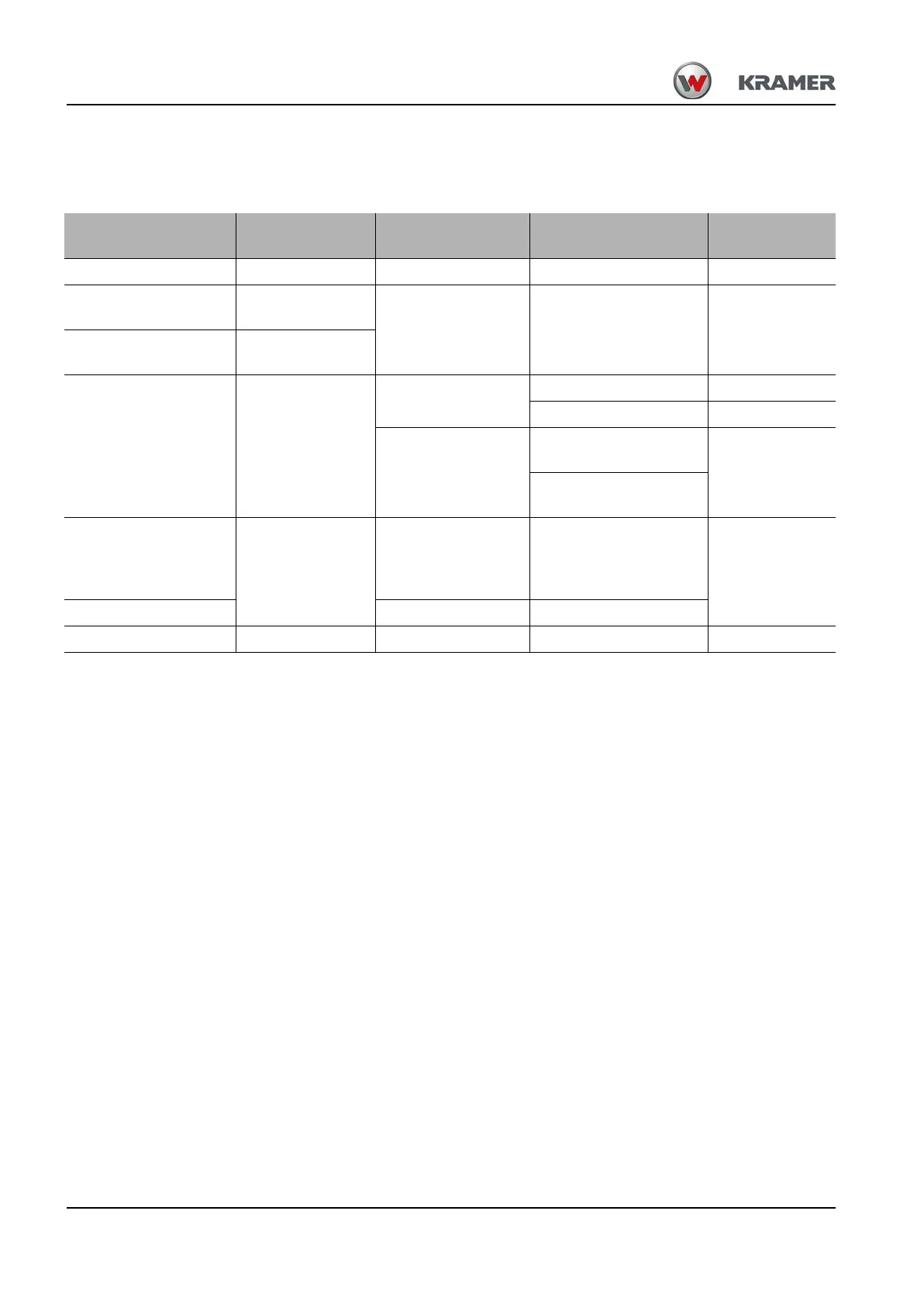

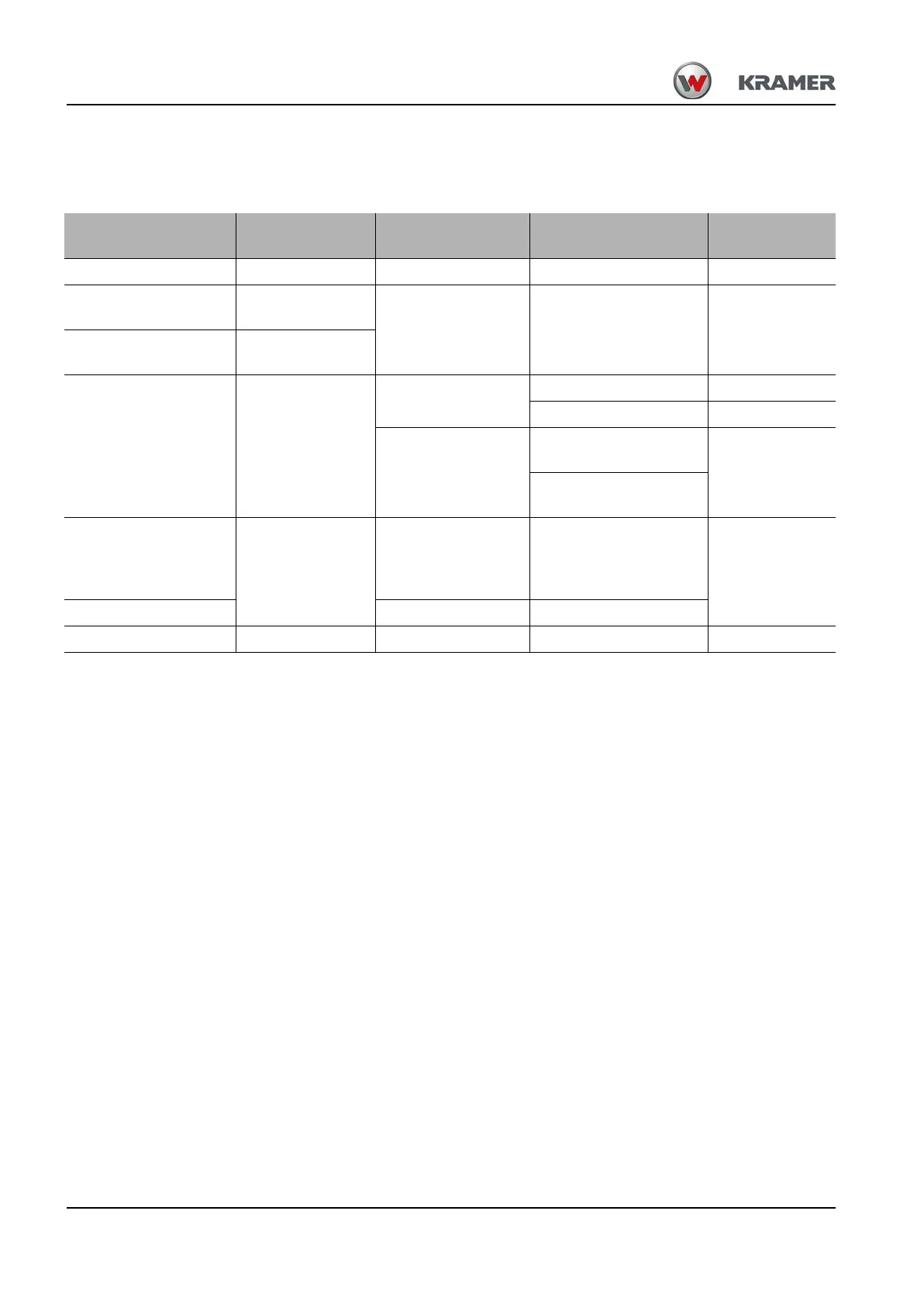

Overview: Fluids and lubricants (part 1)

See next page for more fluids and lubricants.

Component/

application

Capacities

1

Fluid/lubricant

2

SAE grade

Specification

Season/

temperature

Gearbox 0.8 l (0.21 gal) Universal gearbox oil SAE 80 – 90 GL5 Year-round

Front or rear axle

differentials

3

3.0 l (0.8 gal) each

Gearbox oil

4

SAE 90 LS

(Eurolub Gear

LS 80W – 90 GL5)

Year-round

Planetary drives

front or rear axle

3

0.5 l (0.13 gal)

each

Hydraulic system/

hydraulic oil reservoir

approx. 52/40 l

(11.44/10.57 gal)

Hydraulic oil

5

HVLPD 32

6

−30 °C (−22 °F)

HVLPD 46 Year-round

Biodegradable oil

AVILUB

Syntofluid 46

Year-round

PANOLIN HLP

Synth 46

Grease zerks

loader unit/axles

As required

High pressure

multi-purpose

grease

Lithium soap branded

grease AVIALITH EP 2

KP 2 K-30

7

,

Fuchs "gleitmo" 800

8

Year-round

Battery terminals Acid-proof grease SP-B

Attaching

9

pins, shafts – –– –

1. The capacities indicated are approximate values; the oil level check alone is relevant for the correct oil level.

2. Bear in mind the safety data sheet of the engine/machine fluids.

3. Capacity indications for each axle or planetary drive.

4. Specification: API GL 5 MIL-L-2105 D.

5. DIN 51 524/ISO 11158-HM.

6. Used in Scandinavian countries only.

7. Under normal stress

8. Under heavy stress (e.g. for bolts)

9. Notice! Pins and shafts are hard chromium plated and are used dry. After assembly: lubricate pins and shafts using grease zerks.

Loading...

Loading...