Preparing the Separations Module for Operation 27

Selecting a Needle-Wash Solvent

Use a needle-wash solvent based on the sample and mobile phase chemistries, making

sure all solutions/buffers are miscible and soluble. Table 2-1

lists some needle-wash

solvents recommended for use with certain mobile phase conditions. High sample

concentrations may require other needle-wash solvents.

To prime the needle-wash pump:

1. Be sure the needle-wash fluidic lines are properly installed, as described in the

Waters 2690 Separations Module Operator’s Guide

, Section 2.6.6, Installing Needle

Wash and Plunger Seal Wash Reservoirs.

2. Press the

Diag

screen key in the Main screen. The Diagnostics screen appears

(Figure 2-12

).

3. Press the

Prime NdlWsh

screen key. The 30-second needle-wash procedure

begins. If solvent does not flow out of the waste tube within 30 seconds, press

the

Start Again

screen key.

2.4.3 Adjusting the Seal Pack

Adjust the seal pack whenever:

• You start up the Separations Module for the first time. The Separations Module does

not perform injections and compression checks until the seal pack has been

adjusted.

• A “Compression Check Failed” error appears on the screen

• A “Missing Restrictor” alarm appears during a diagnostic procedure

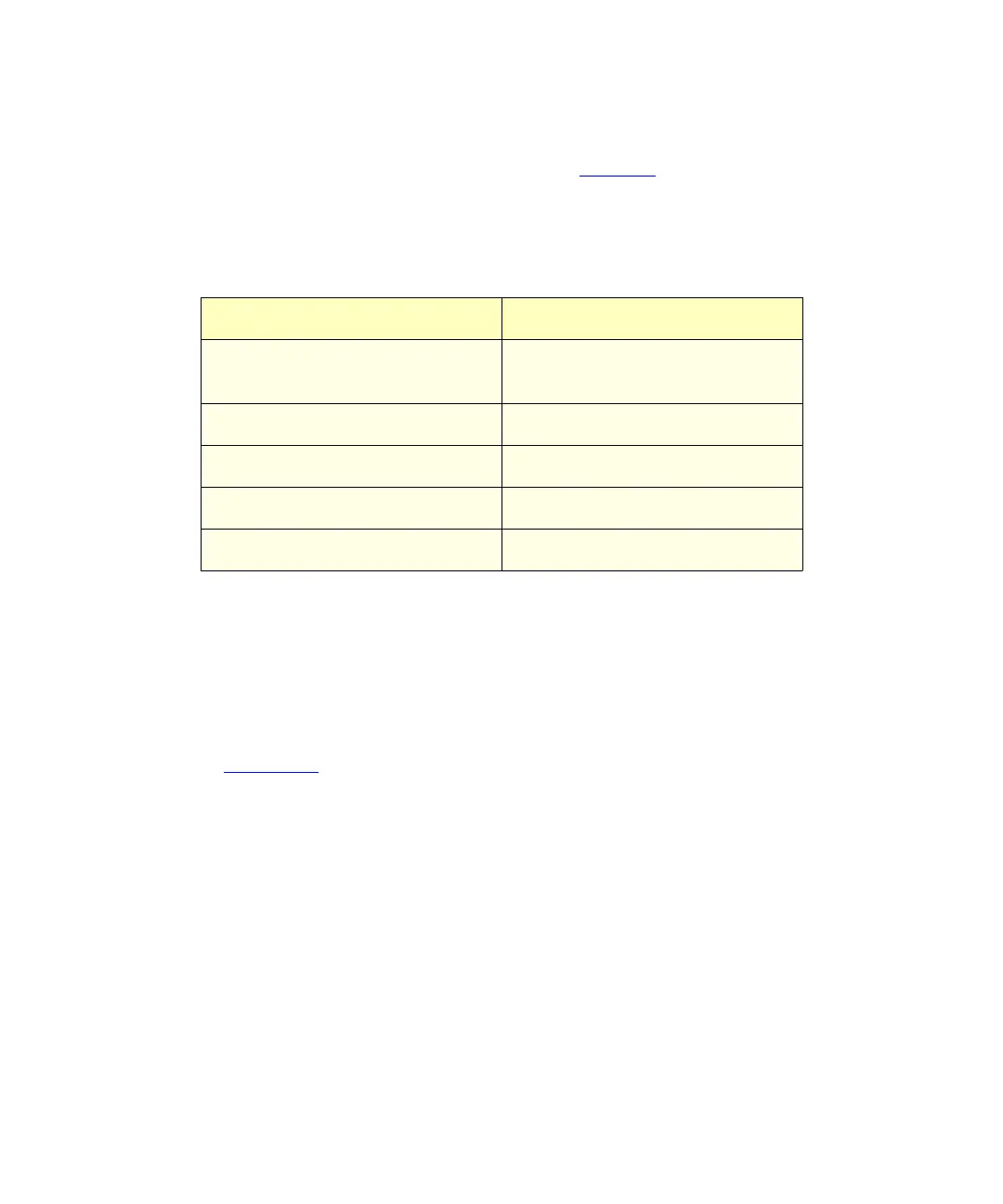

Table 2-1 Suggested Needle Wash Solvents

Chromatographic Condition Needle Wash Solvent

Buffered aqueous,

reversed-phase

90% H

2

O, 10% MeOH

Non-aqueous, reversed-phase 100% MeOH

Normal phase Mobile phase

GPC Mobile phase

Ion exchange H

2

O

Loading...

Loading...