32 Performing a Direct Control Run

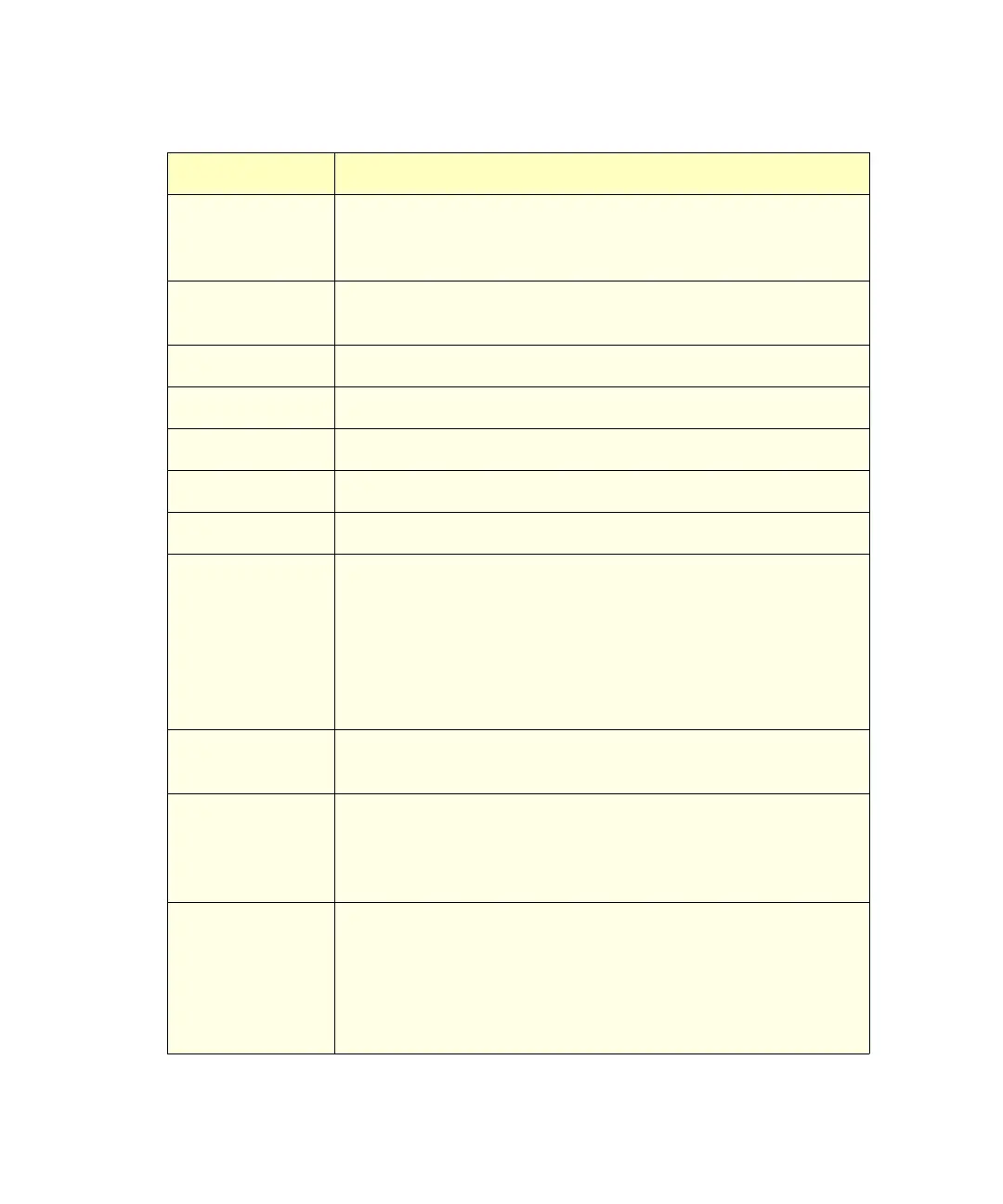

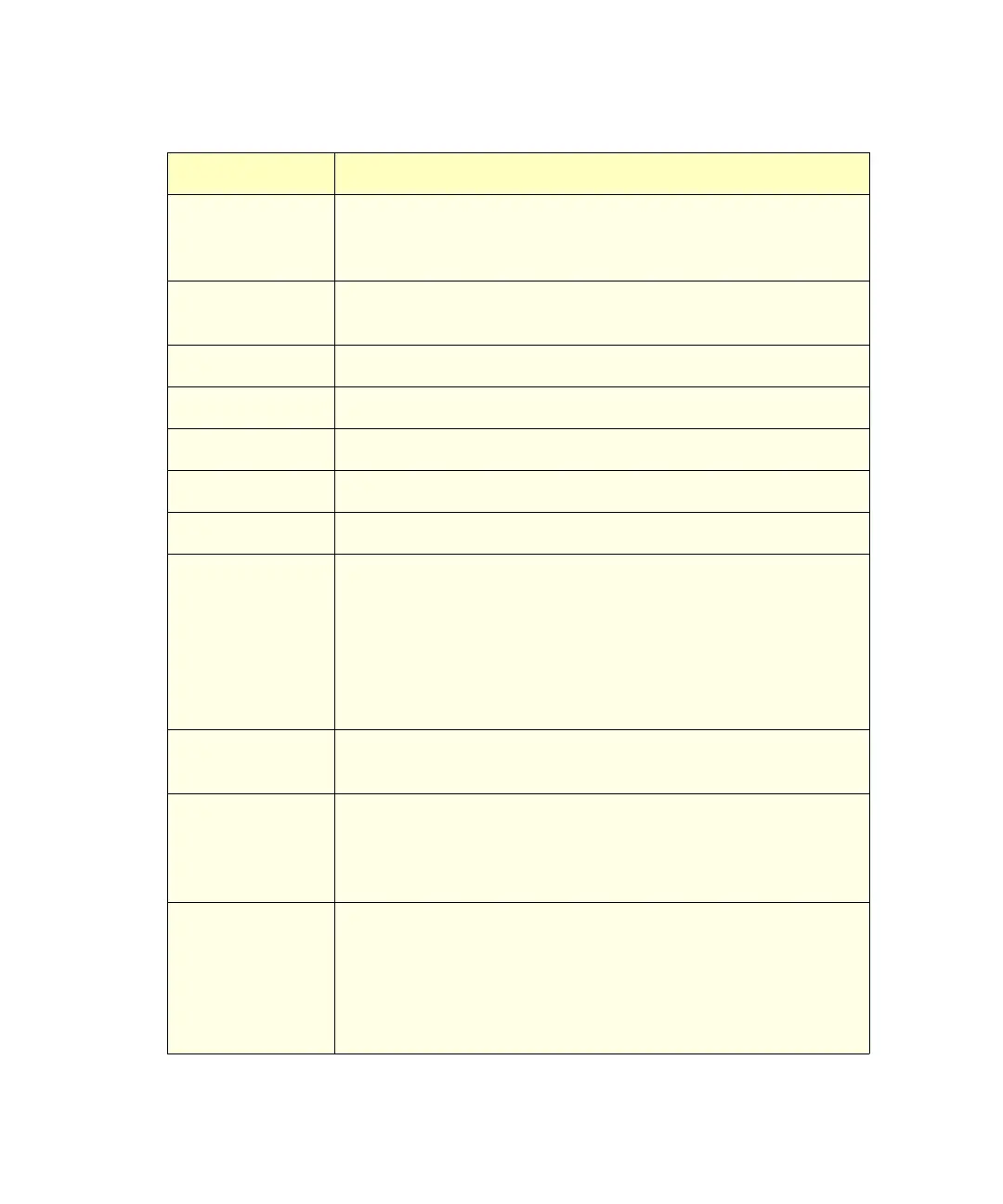

Table 3-1 Status Screen Parameters

Parameter Description

Method Indicates the current separation method. When you change

any parameter in the Status screen, this field changes to

<direct>.

Flow Indicates the current flow rate of the solvent management

system.

System Indicates the current system pressure in psi, bar, or kPa.

Sample: Set Indicates the user-specified sample compartment temperature.

Sample: Current Indicates the current actual sample compartment temperature.

Composition Indicates the current solvent composition.

S1 – S4 Indicates the status of the event switches on the I/O connector.

Degasser

•Mode

• Vac pump

• Pressure

Indicates the status of the in-line vacuum degasser (if

installed).

Selects the mode of operation: Normal, Continuous, or

Disable

Indicates whether the vacuum pump motor is active or idle.

Current vacuum level in psi, bar, or kPa.

Sparge Indicates the sparge rate cycle for each solvent (if sparge is

installed)

V1 – V4 Indicates the position (open or closed) of each of the valves in

the sample management system. See the

Waters 2690

Separations Module Operator’s Guide

, Section 1.3, Sample

Management System Overview, for a description of the valves.

Pressure Ripple

• Max psi

•Min psi

•Delta psi

Indicates pressure readings in the solvent management system

for the last minute.

Maximum pressure.

Minimum pressure.

Peak-to-peak pressure difference.

Loading...

Loading...