03/2016 – UM-MT-EN-01 121

It is recommended to enter maintenance and repairs in the Maintenance Re-

port (see Section Error! Reference source not found. Page Error!

Bookmark not defined.).

Significant measures for inspection of the treadmill:

Treadmill installation

Running surface belt

Drive unit and the lifting system

Nuts and bolts

Secondary bearing and guide rollers

Electronics

For further information on maintenance procedures, refer to the separate service manu-

al.

9.3 Lubrication

9.3.1 Bearings

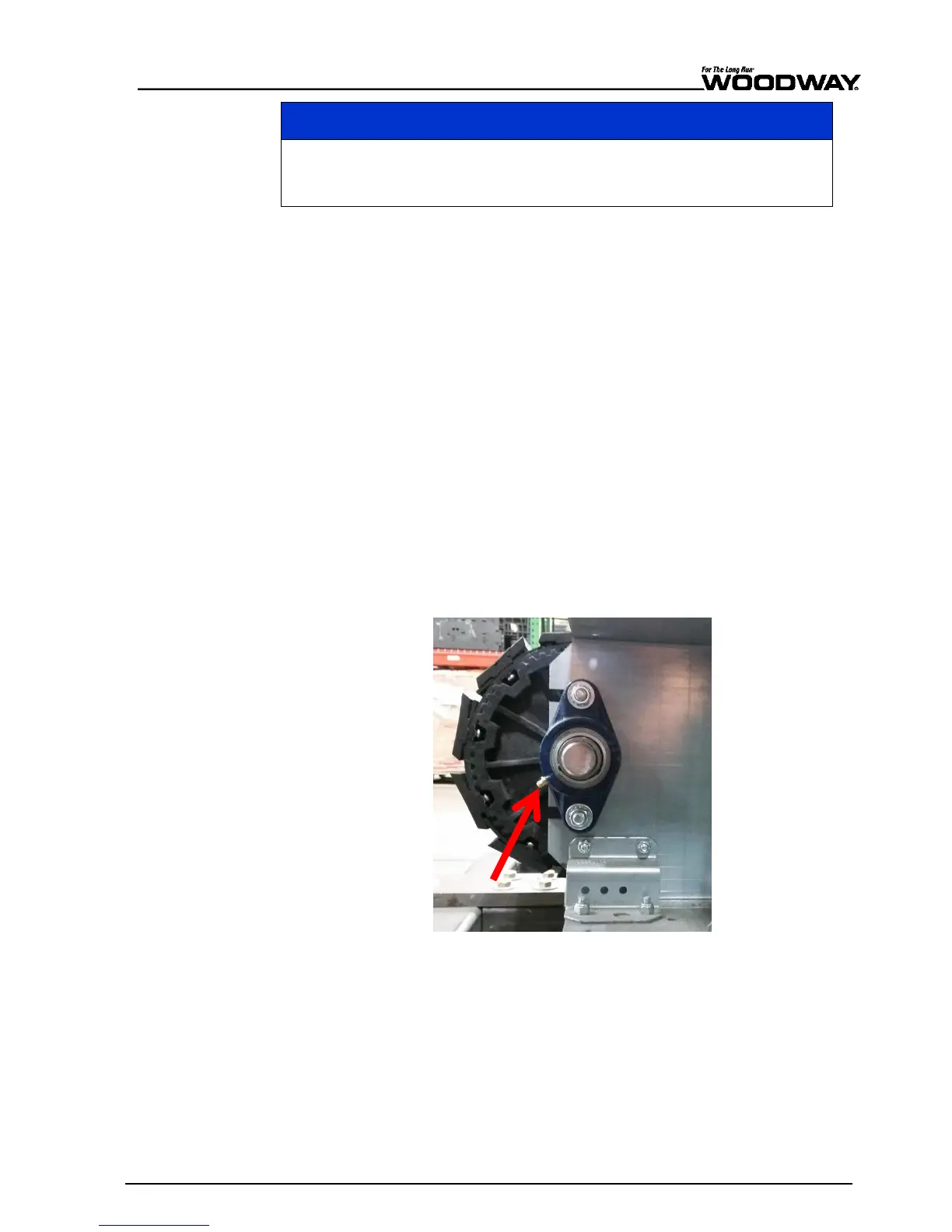

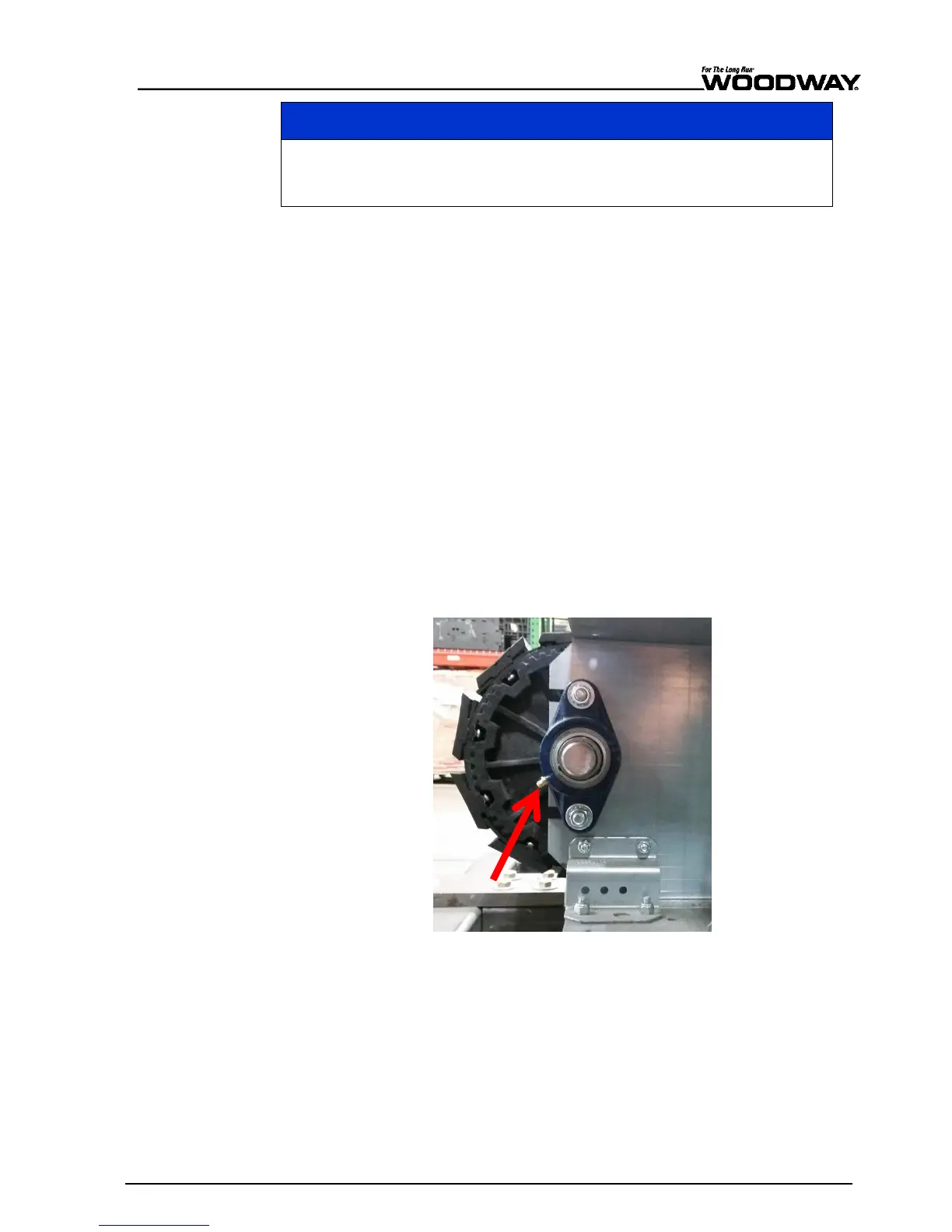

Almost all bearings in the treadmill have been lubricated by the manufacturer and need

not be greased. The 4 bearings at the front and rear axles must be lubricated once a

year with one stroke of the grease gun.

Remove the side panels when lubricating bearings.

One pump of grease can be inserted into zerk fittings on bearings (need a grease

gun with a flex bit).

If necessary, tighten bolts that secure bearings to the frame.

Fig. 114 Lubrication, axle bearing

9.3.2 Running Surface Belt, Drive Axle

The teeth on the bottom of the tread belt are sufficiently lubricated in the factory to

minimize noise. The teeth do not need to be lubricated. When the running surface belt

rubs on the side of the guide rollers, the use of a small amount of lubricant (Molykote or

similar product) on the edges of the v-guide can contribute to noise reduction. To ensure

correct tread belt alignment, apply grease to the teeth on the rear driving axle.

Loading...

Loading...