3-5

3

Installation

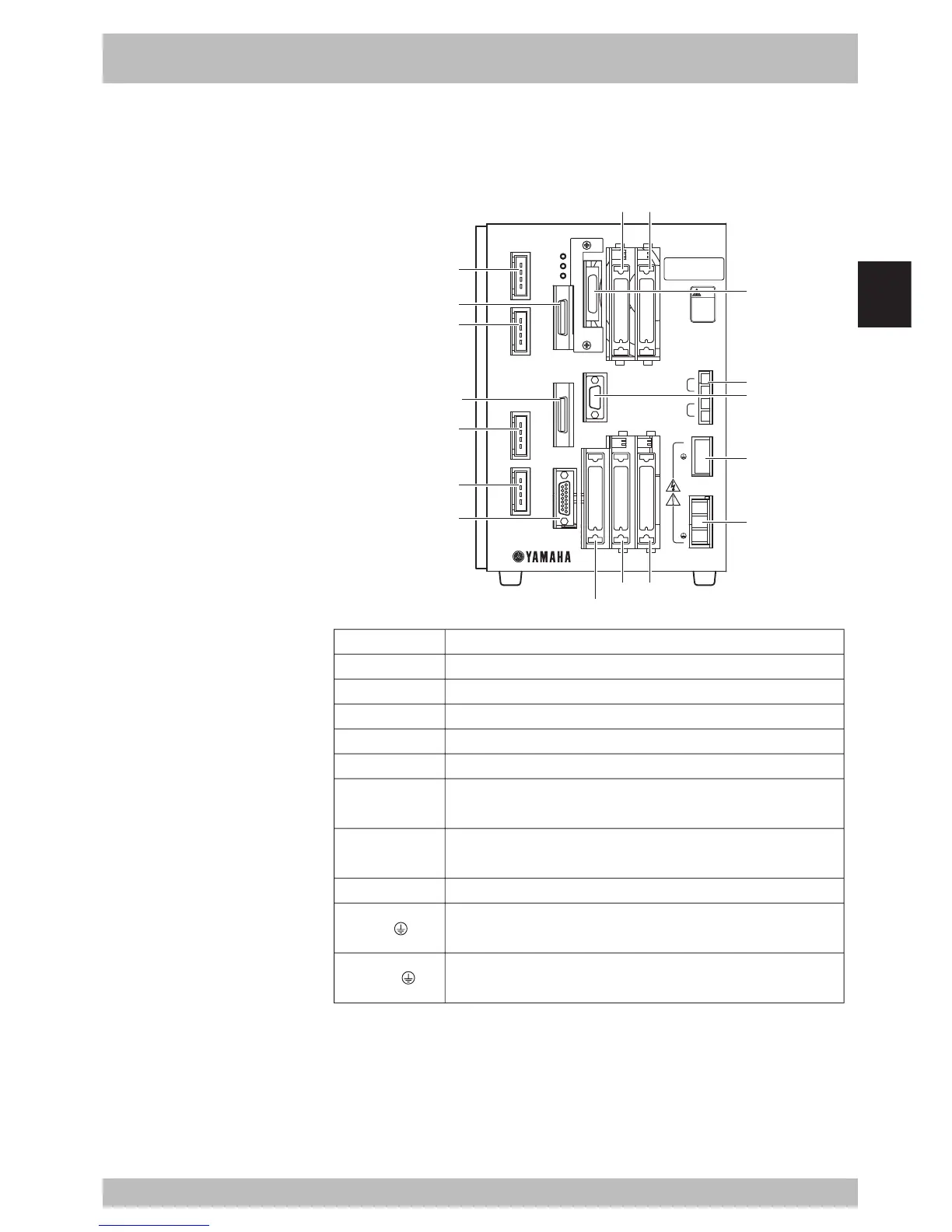

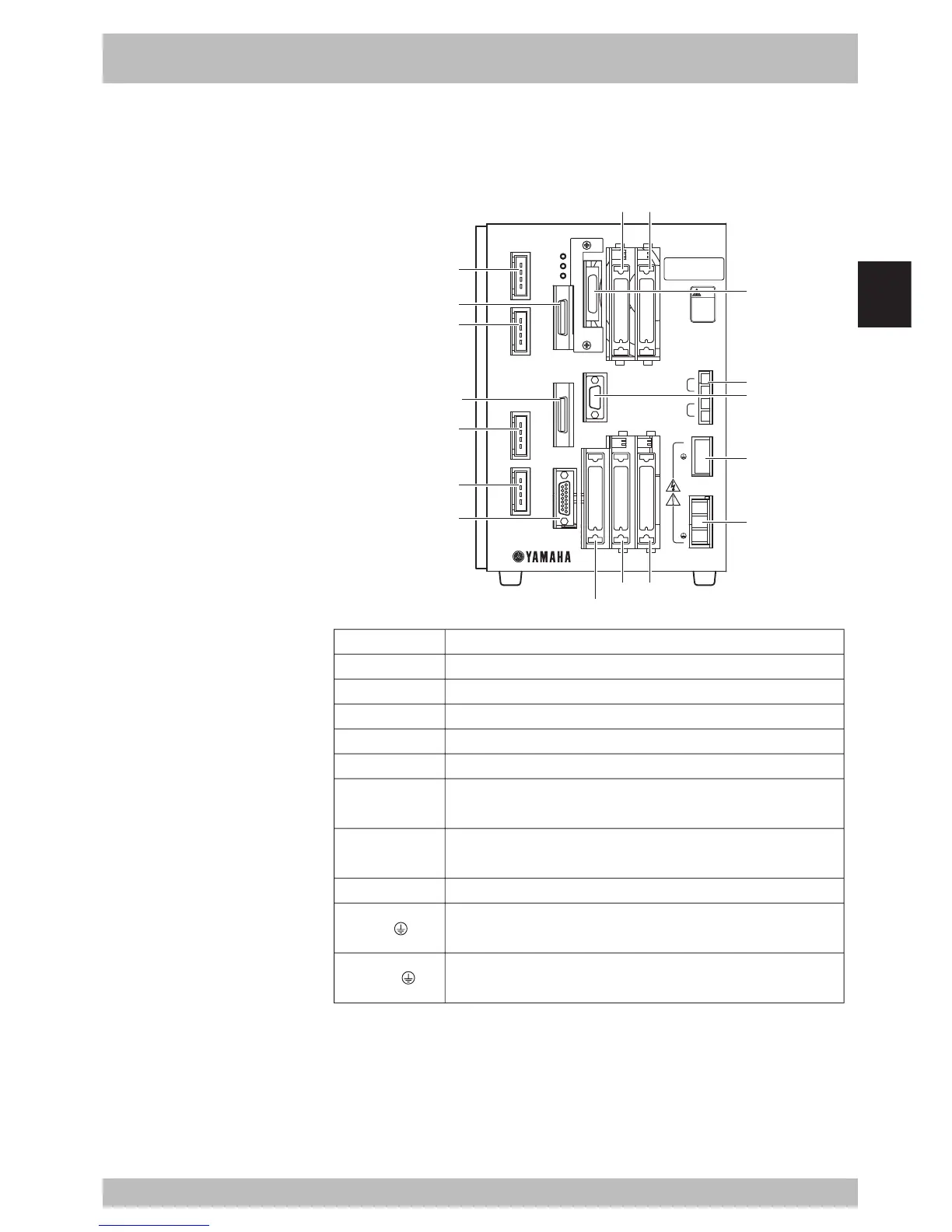

3. Connector names

Connector names, locations and functions are shown below.

Fig. 3-3-1 RCX connectors

RCX142

MOTOR

XM

YM

ZM

RM

PWR

SRV

ERR

SAFETY

MPB

COM

STD.DIO

RGEN

ACIN

P

N

L

N

ROB

I/O

XY

ROB

I/O

ZR

OP.1 OP.3

OP.2 OP.4

200-230V~

50-60Hz

MAX.2500VA

BATT

ZR

XY

MODEL.

SER. NO.

MANUFACTURED

FACTORY AUTOMATION EQUIPMENT MADE IN JAPAN

注意

CAUTION

取扱説明書参照

READ INSTRUCTION

MANUAL

COM

MPB

SAFETY

XM

YM

ZM

RM

OP.1

OP.3

OP.2

OP.4

RGEN

ACIN

ROBI/O XY

ROBI/O ZR

STD.DIO

BATT

FunctionConnector name

XM/YM/ZM/RM

ROB I/O [XY/ZR]

SAFETY

MPB

COM

STD.DIO

OP.1-4

BATT [XY/ZR]

REGN [P/ /N]

AC IN [L/N/ ]

Connectors for servomotor drive.

Connectors for servomotor feedback and sensor signals.

Input/output connector for safety function such as emergency stop.

Connector for MPB.

RS-232C interface connector.

Connector for dedicated input/output and standard general-purpose

input/output.

Connectors attached to optional expansion I/O boards.

(OP.2 and OP.4 cannot be used with RCX142-T.)

Battery connector for absolute backup.

Connector for regenerative unit.

(Cannot be connected to RCX142-T.)

Terminal block for power cable. Use ring-tongue terminals to make

connections.

w

WARNING

To prevent electrical shocks,

never touch the RGEN and AC IN

terminals when power is

supplied to the robot controller.

Loading...

Loading...