n

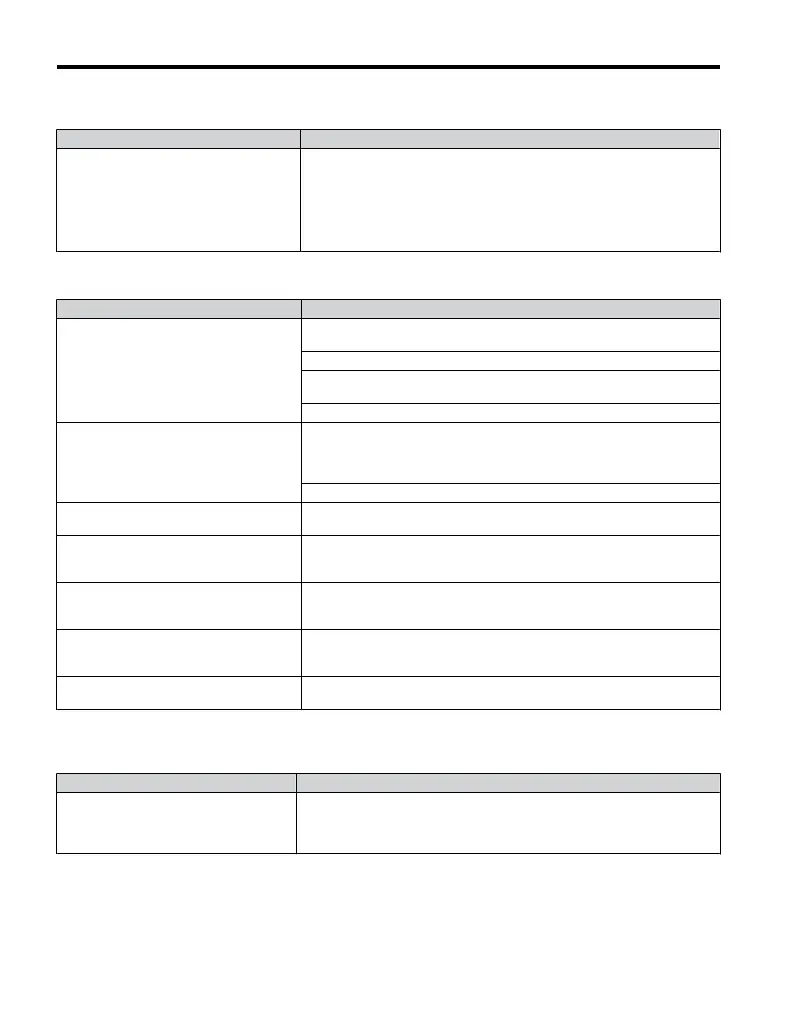

Motor Stalls During Acceleration or With Large Loads

Cause Possible Solutions

Load is too heavy.

Take the following steps to resolve the problem:

• Reduce the load.

• Increase the acceleration time.

• Increase motor capacity.

• Although the drive has a Stall Prevention function and a Torque

Compensation Limit function,

accelerating too quickly or trying to drive

an excessively large load can exceed the capabilities of the motor.

n

Motor Will Not Accelerate or the Acceleration Time is Too Long

Cause Possible Solutions

Frequency reference is too low.

• Check the maximum output frequency (E1-04).

• Increase E1-04 if it is set too low.

Check U1-01 for proper frequency reference.

Check if a frequency reference signal switch has been set to one of the multi-

function input terminals.

Check for low gain level set to terminal A1 (H3-03).

Load is too heavy.

• Reduce the load so that the output current remains within the

motor-rated current.

• In extruder and mixer applications, the load

will sometimes increase as

the temperature drops.

Check if the mechanical brake is fully releasing as it should.

Acceleration time has been set too long.

Check if the acceleration time parameters have been set too long (C1-01,

-03).

Motor characteristics and drive parameter

settings are incompatible with one another

in V/f Control.

• Set the correct V/f pattern so that it matches the characteristics of the

motor being used.

The Stall Prevention level during

acceleration and deceleration set too low.

• Check the Stall Prevention level during acceleration (L3-02).

• If L3-02 is set too low, acceleration will take a fair amount of time.

• Increase L3-02.

The Stall Prevention level during run has

been set too low.

• Check the Stall Prevention level during run (L3-06).

• If L3-06 is set too low, speed will drop as the drive outputs torque.

• Increase the setting value.

Drive reached the limitations.

• Be aware that V/f Control is comparatively limited when it comes to

producing torque at low speeds.

n

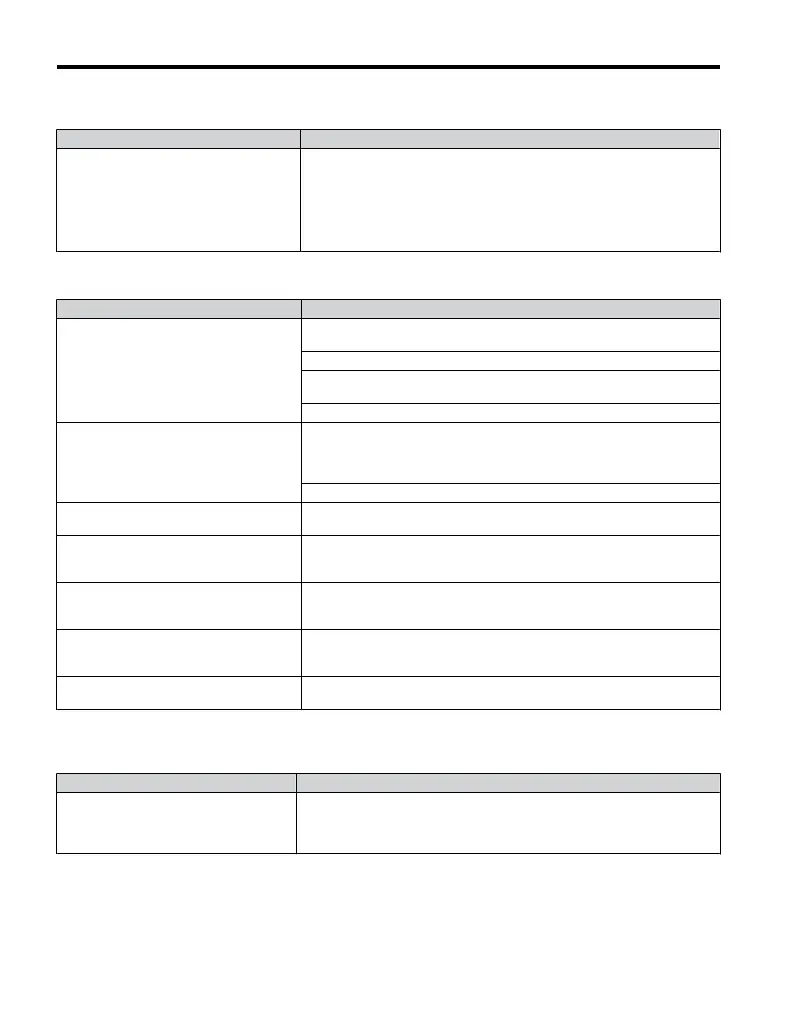

Drive Frequency Reference Differs from the Controller Frequency

Reference Command

Cause Possible Solutions

The analog input frequency gain and bias

are set to incorrect values.

• Check the main speed frequency reference terminal input gain level

assigned to terminal A1, as well as

the frequency reference input bias to

terminal A1 (parameters H3-03 and H3-04).

• Set these parameters to the appropriate values.

5.8 Troubleshooting without Fault Display

146

YASKAWA ELECTRIC TOEP C710606 25B YASKAWA AC Drive J1000 Installation & Start-Up Manual

2/6/2008-14:44

Loading...

Loading...