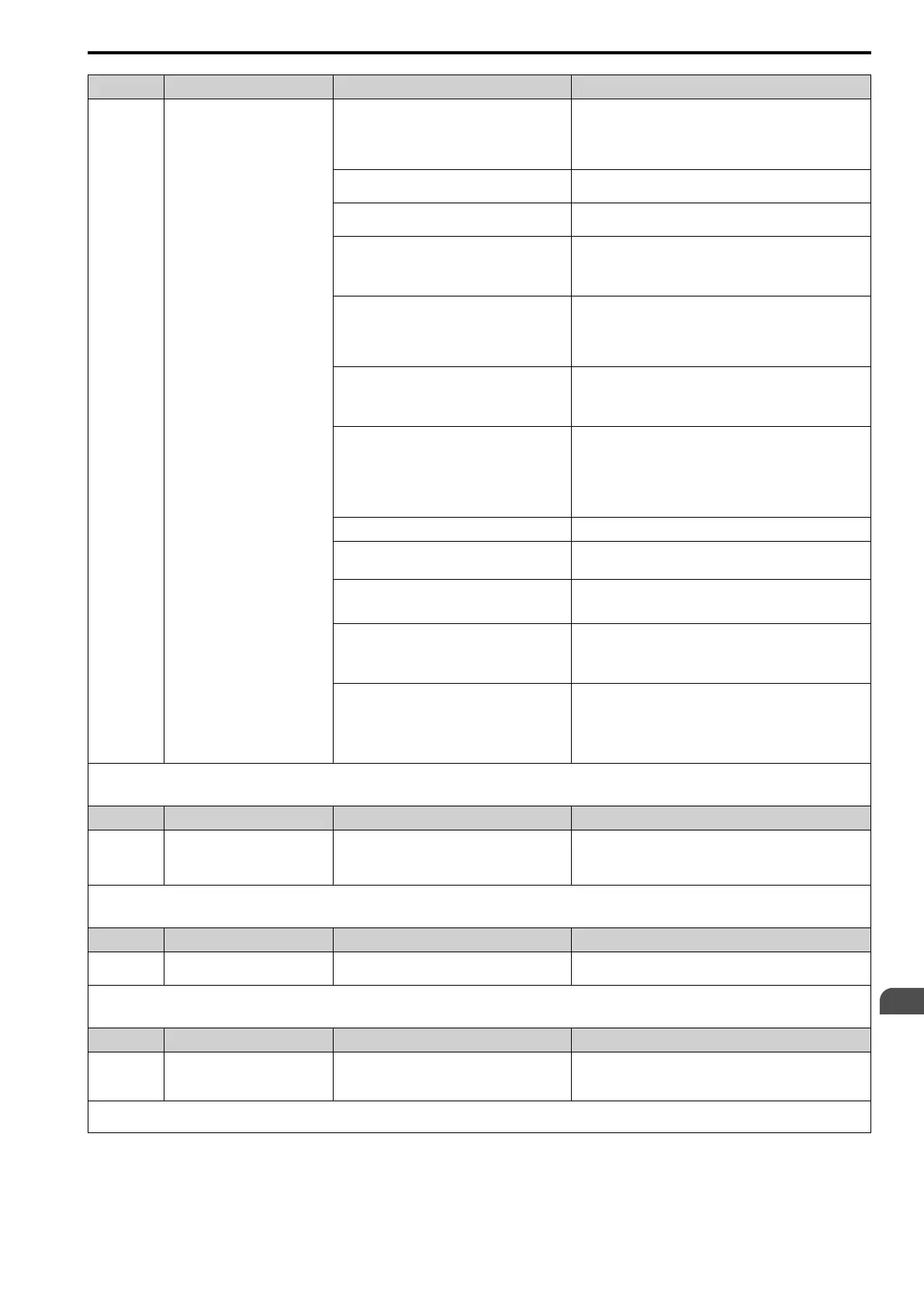

Troubleshooting

7

7.4 Fault

YASKAWA SIEPC71061753C GA500 Technical Manual 265

Code Name Causes Possible Solutions

The V/f pattern settings are incorrect. • Examine the ratios between the V/f pattern frequency and

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust E1-04 to E1-10 [V/f Pattern Parameters]. For motor 2,

adjust E3-04 to E3-10.

The torque compensation gain is too large. Decrease the value set in C4-01 [Torque Compensation Gain] to

make sure that the motor does not stall.

Electrical interference caused a problem. Examine the control circuit lines, main circuit lines, and ground

wiring, and decrease the effects of electrical interference.

The gain during overexcitation operation is too

large.

• Find the time when the fault occurs.

• If the fault occurs at the same time as overexcitation operation,

decrease the value set in n3-13 [OverexcitationBraking (OEB)

Gain] and consider the motor flux saturation.

The drive received a Run command while the motor

was coasting.

• Examine the sequence and input the Run command after the

motor fully stops.

• Set b3-01 = 1 [Speed Search at Start Selection = Enabled] or

set H1-xx = 61, 62 [Speed Search from Fmax or Fref] to input

speed search commands from the MFDI terminals.

In PM Control Methods, the setting of the motor

code is incorrect.

• Enter the correct motor code to E5-01 [PM Motor Code

Selection] as specified by the PM motor.

• For specialized motors, refer to the motor test report and set

E5-xx [PM Motor Settings] correctly.

If the drive detects the fault at start or in the low

speed range (10% or less) and n8-57 = 1 [HFI

Overlap Selection = Enabled] for PM Control

methods, the high frequency injection gain is too

high.

• Set E5-xx [PM Motor Parameters] correctly or do Rotational

Auto-Tuning.

• Decrease the value of n8-41 [HFI P Gain] in 0.5-unit

increments.

Note:

Set n8-41 > 0.0 for IPM motors.

The control method is set incorrectly for the motor. Set A1-02 [Control Method Selection] correctly.

The motor main circuit cable is too long. • Replace the drive with a larger capacity model.

• Decrease C6-02 [Carrier Frequency]. Or set C6-02 = B.

Speed search does not complete at start when you

set A1-02 = 8 [EZ Vector Control] and use an

induction motor.

When E9-01 = 0 [Motor Type Selection = Induction (IM)], set b3-

24 = 2 [Speed Search Method Selection = Current Detection

Speed Search].

An overcurrent occurred during overexcitation

deceleration.

• Decrease the value set in n3-13 [OverexcitationBraking (OEB)

Gain].

• Decrease the value set in n3-21 [HSB Current Suppression

Level].

When you use an IE3 premium efficiency motor. Use these values to adjust the parameters.

• b3-03 [Speed Search Deceleration Time] = default value × 2

• L2-03 [Minimum Baseblock Time] = default value × 2

• L2-04 [Powerloss V/f Recovery Ramp Time] = default value ×

2

Note:

• This fault occurs if the drive sensors detect a drive output current more than the specified overcurrent detection level.

• Do a Fault Reset to clear the fault.

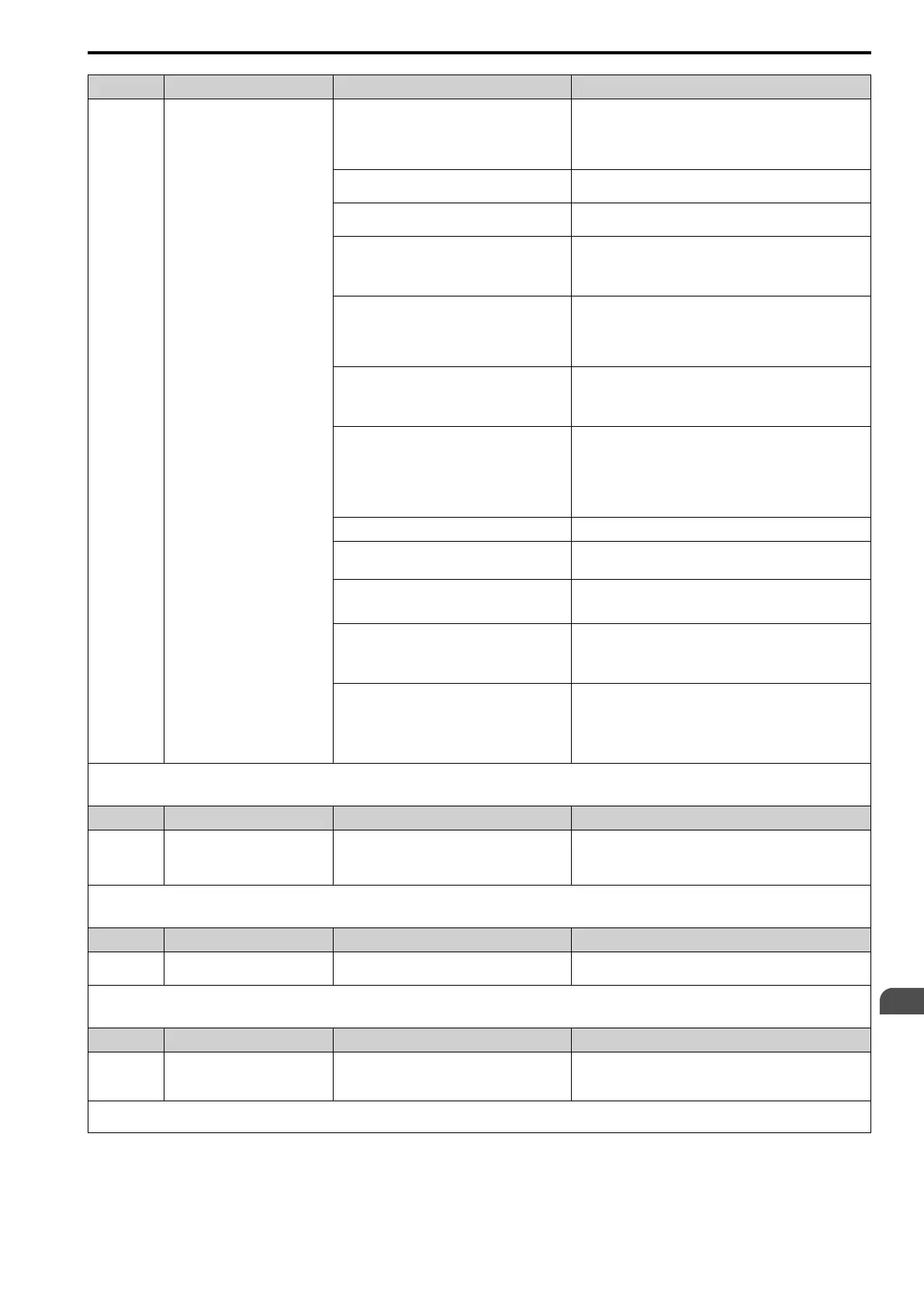

Code Name Causes Possible Solutions

oC2 Overcurrent2

When A1-02 = 5, 6, 8 [Control Method Selection =

OLV/PM, AOLV/PM, or EZOLV], the output current

is more than the value set in L8-27 [Overcurrent

Detection Gain].

Correct the value set in L8-27.

Note:

• This fault occurs if the drive sensors detect a drive output current more than the specified overcurrent detection level.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

oFA00 Option Not Compatible with Port

The option connected to connector CN5 is not

compatible.

Connect a correct option.

Note:

• Do a Fault Reset to clear the fault.

• Fault trace is not available for these faults.

Code Name Causes Possible Solutions

oFA01 Option Fault/Connection Error

You changed the option card connected to

connector CN5 during operation.

1. De-energize the drive.

2. Refer to the option card manual and correctly connect the

option card to the connector on the drive.

Note:

Do a Fault Reset to clear the fault.

Loading...

Loading...