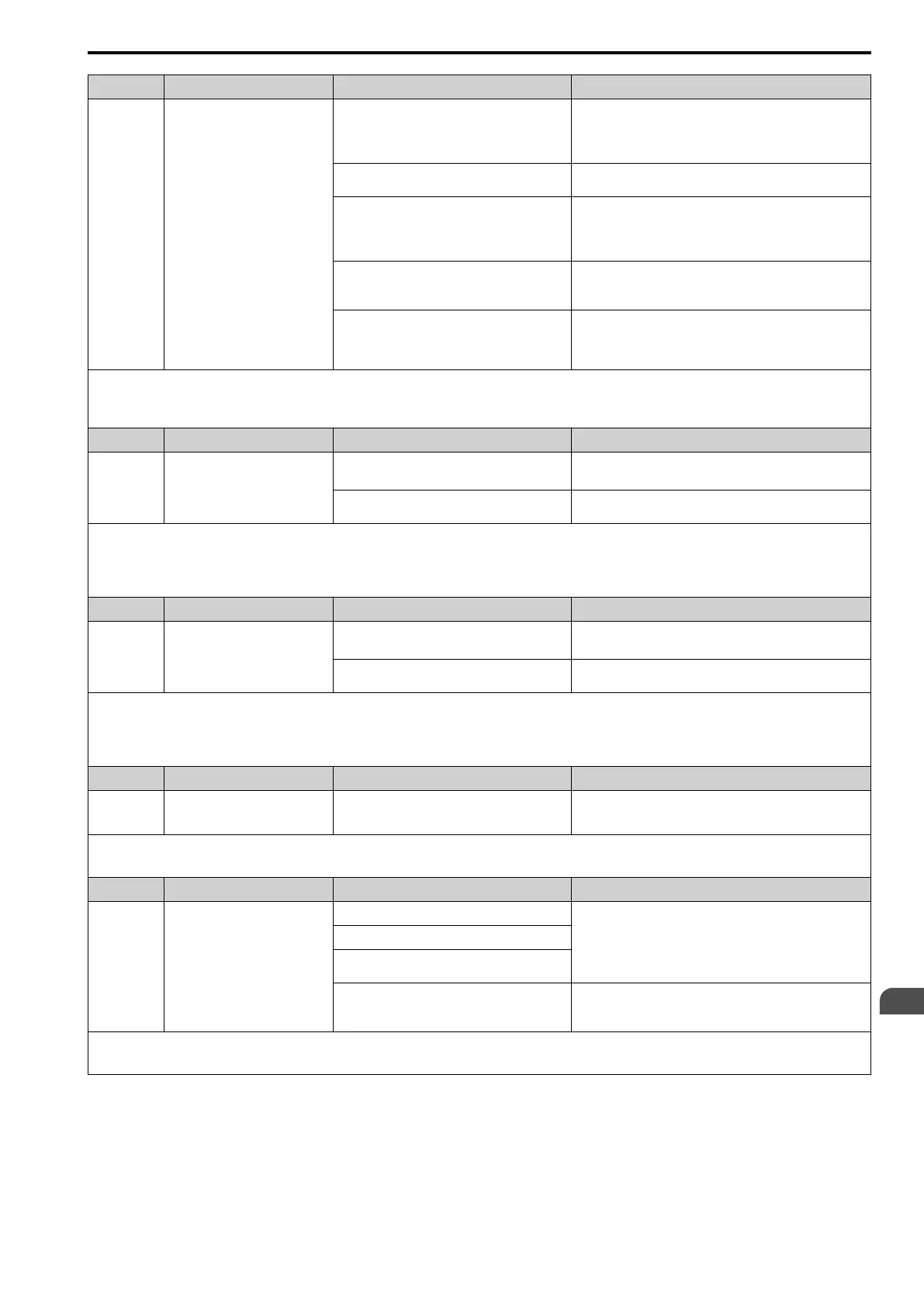

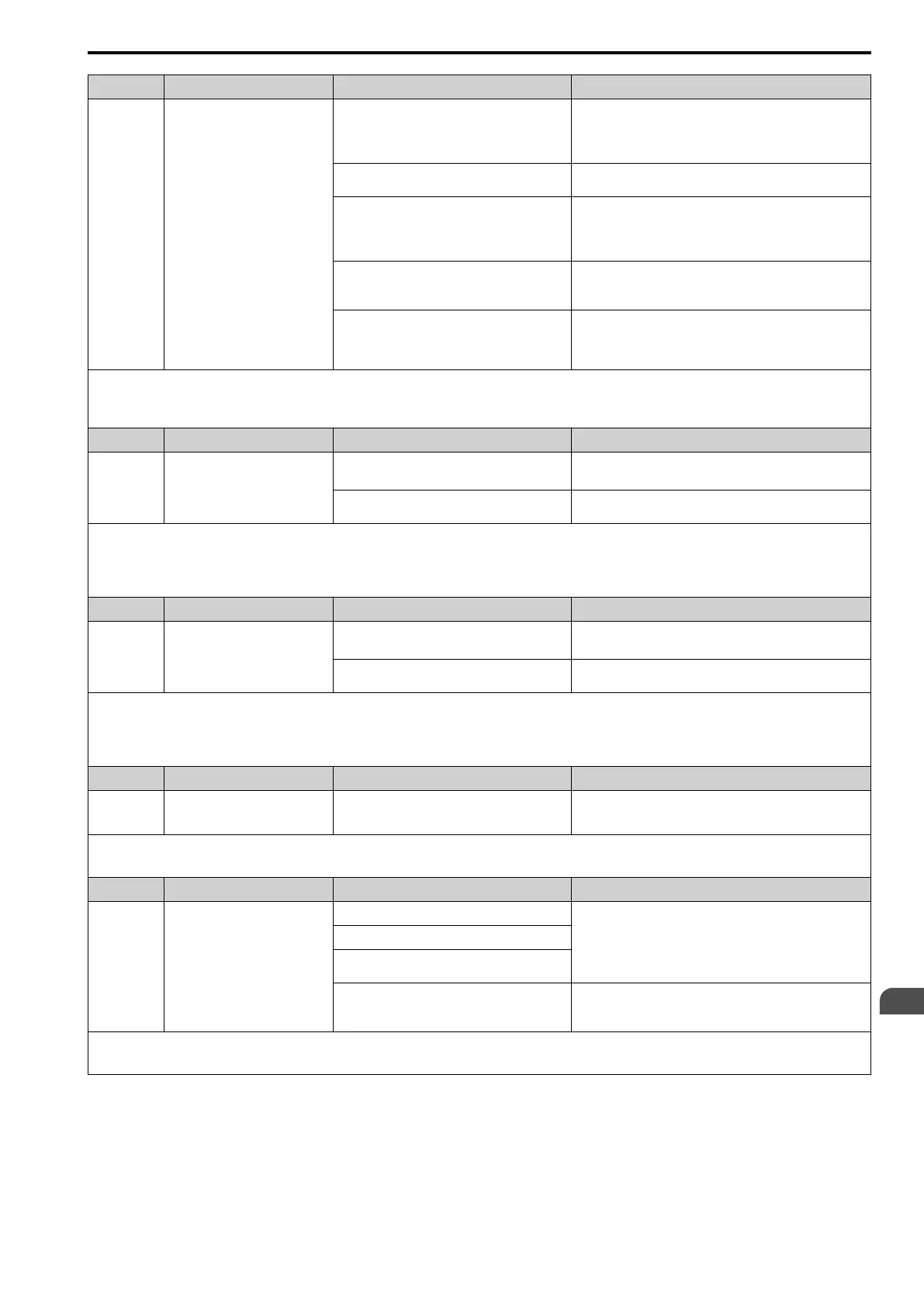

Troubleshooting

7

7.4 Fault

YASKAWA SIEPC71061753C GA500 Technical Manual 271

Code Name Causes Possible Solutions

Overload occurred while running at low speed. • Decrease the load when running at low speed.

• Replace the drive with a larger capacity model.

• Decrease the value set in C6-02 [Carrier Frequency

Selection].

The torque compensation gain is too large. Decrease the value set in C4-01 [Torque Compensation Gain] to

make sure that the motor does not stall.

The speed search-related parameters are set

incorrectly.

• Examine the settings for all speed search-related parameters.

• Adjust b3-03 [Speed Search Deceleration Time].

• Set b3-24 = 1 [Speed Search Method Selection = Speed

Estimation] after Auto-Tuning.

Phase loss in the input power supply is causing the

output current to change.

• Correct errors with the wiring for main circuit drive input

power.

• Make sure that there is no phase loss, and repair problems.

Overload occurred during overexcitation

deceleration.

• Decrease the value set in n3-13 [OverexcitationBraking (OEB)

Gain].

• Decrease the value set in n3-21 [HSB Current Suppression

Level].

Note:

• The drive detects this fault if the electronic thermal protector of the drive started the drive overload protection.

• Do a Fault Reset to clear the fault.

• L5-07 [Fault Reset Enable Select Grp1] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL3 Overtorque Detection 1

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-02 [Torque Detection Level 1] and L6-03 [Torque

Detection Time 1] settings.

Note:

• The drive detects this fault if the drive output current is more than the level set in L6-02 for longer than L6-03.

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-01 [Torque Detection Selection 1].

• L5-07 [Fault Reset Enable Select Grp1] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL4 Overtorque Detection 2

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-05 [Torque Detection Level 2] and L6-06 [Torque

Detection Time 2] settings.

Note:

• The drive detects this fault if the drive output current is more than the level set in L6-05 for longer than L6-06.

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-04 [Torque Detection Selection 2].

• L5-07 [Fault Reset Enable Select Grp1] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL5 Mechanical Weakening Detection 1

The drive detected overtorque as specified by the

conditions for mechanical weakening detection set

in L6-08 [Mechanical Fatigue Detect Select].

Do a deterioration diagnostic test on the machine side.

Note:

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-08.

Code Name Causes Possible Solutions

oL7 High Slip Braking Overload

The load inertia is too large.

An external force on the load side rotated the motor.

Something is preventing deceleration on the load

side.

• Decrease deceleration times in C1-02, C1-04, C1-06, and C1-

08 [Deceleration Times] for applications that do not use High

Slip Braking.

• Use a braking resistor to decrease the deceleration time.

The value set in n3-04 [HSB Overload Time] is too

small.

• Increase the value set in n3-04.

• Connect a thermal overload relay to the motor, and set n3-04 =

1200 s (maximum value).

Note:

• The drive detects this fault if the output frequency is constant for longer than n3-04.

• Do a Fault Reset to clear the fault.

Loading...

Loading...