3.2 Operating Procedures for Utility Functions

3.2.28 Advanced Autotuning without Reference (Fn201)

3-76

Troubleshooting Problems in the Operation

This section provides information on troubleshooting problems that can

occur in the operation.

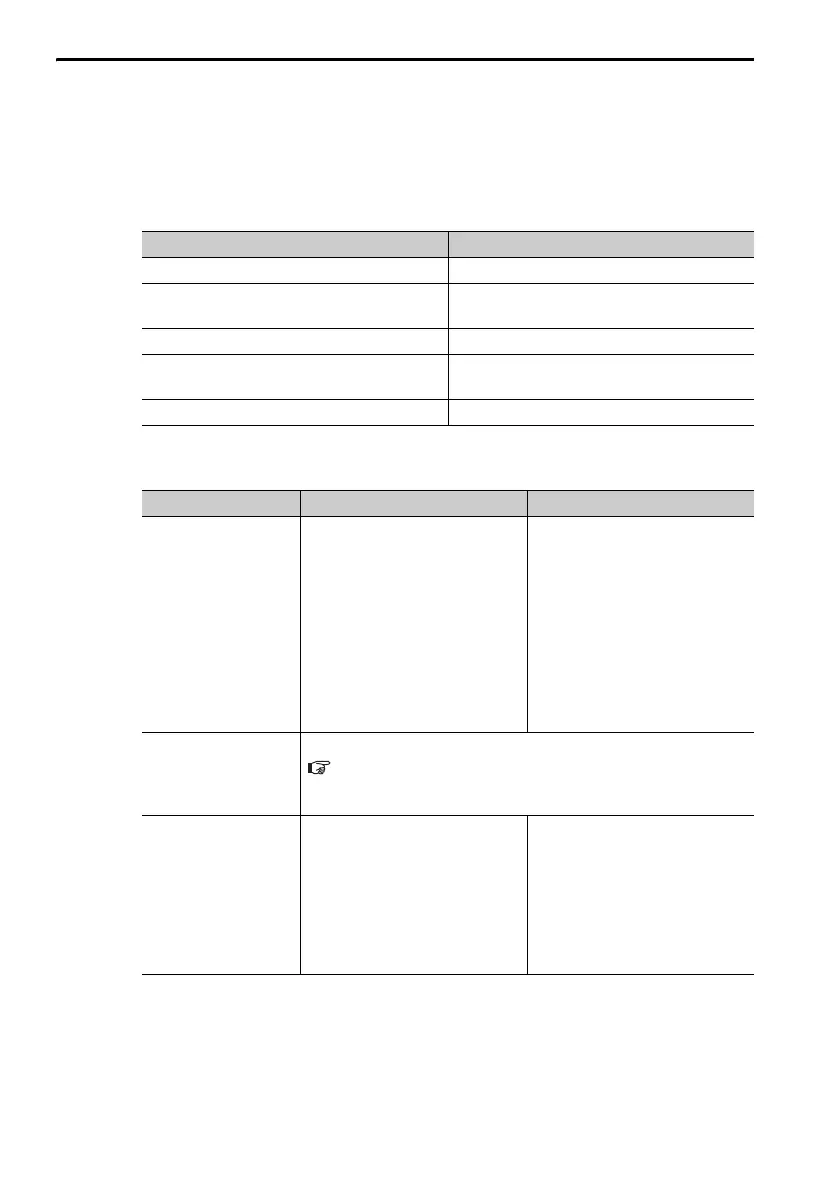

NO-OP Flashes on the Display

ERROR Flashes on the Display

Probable Cause Corrective Action

The main circuit power supply is OFF. Turn ON the main circuit power supply.

An alarm or warning occurred.

Remove the cause of the alarm or

warning.

Overtraveling occurred. Remove the cause of overtraveling.

Gain settings 2 was selected with the

gain selection.

Disable automatic gain switching.

The HWBB was activated. Release the HWBB.

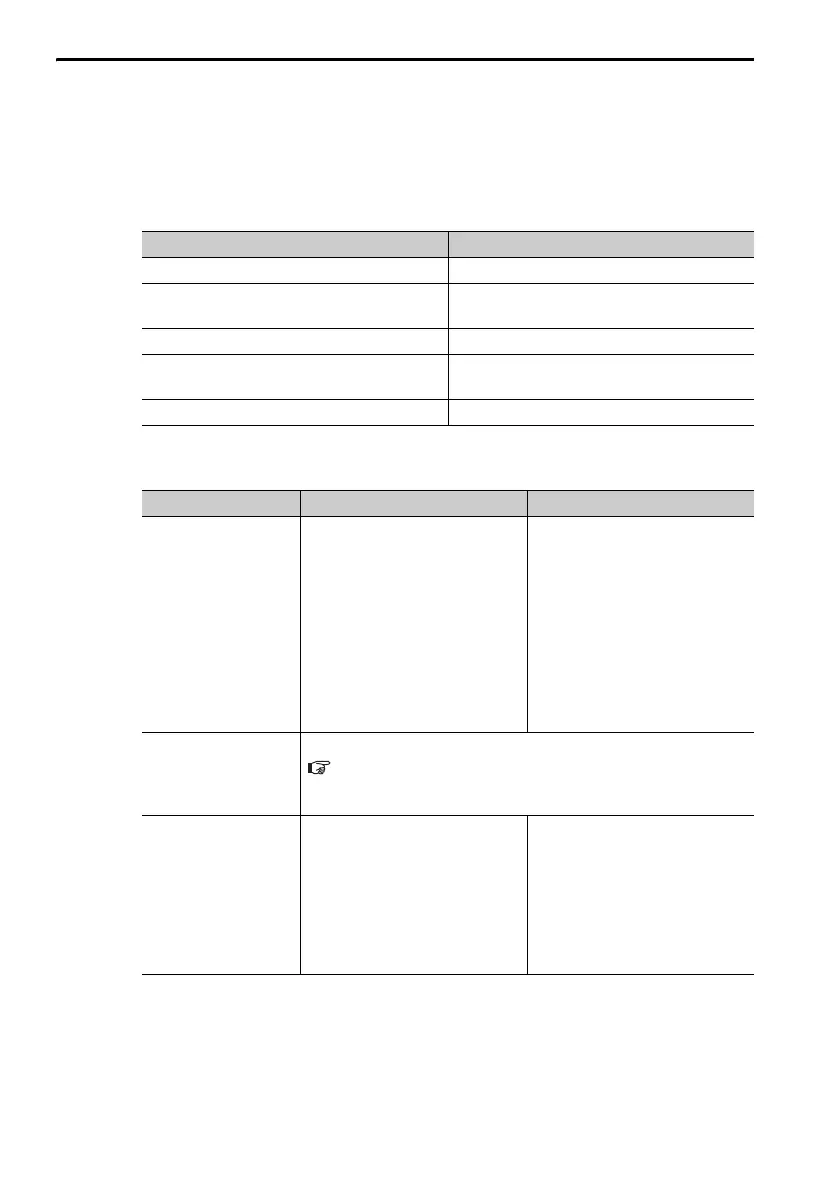

Error Probable Cause Corrective Action

The gain adjust-

ment was not suc-

cessfully

completed.

Machine vibration is occur-

ring or the /COIN (Position-

ing Completion) output

signal is turning ON and

OFF when the Servomotor

stops.

• Increase the setting of

Pn522 (Positioning Com-

pleted Width).

• Change the mode from 2

to 3.

• If machine vibration

occurs, suppress the

vibration with the anti-res-

onance control function

and the vibration suppres-

sion function.

An error occurred

during calculation

of the moment of

inertia.

Refer to the following section.

3.2.28 Advanced Autotuning without Reference (Fn201) -

Errors during Calculation of Moment of Inertia on page

3-78

Travel distance

setting error

The travel distance is set to

approximately 0.5 rotation

or less, which is less than

the minimum travel dis-

tance for adjustment. For a

Direct Drive Servomotor

(SGMCS or SGMCV), it is

set to 0.05 rotations.

Increase the travel dis-

tance. (We recommend that

you set the number of motor

rotations to approximately

3.)

Continued on next page.

Loading...

Loading...