3.2 Operating Procedures for Utility Functions

3.2.28 Advanced Autotuning without Reference (Fn201)

3-78

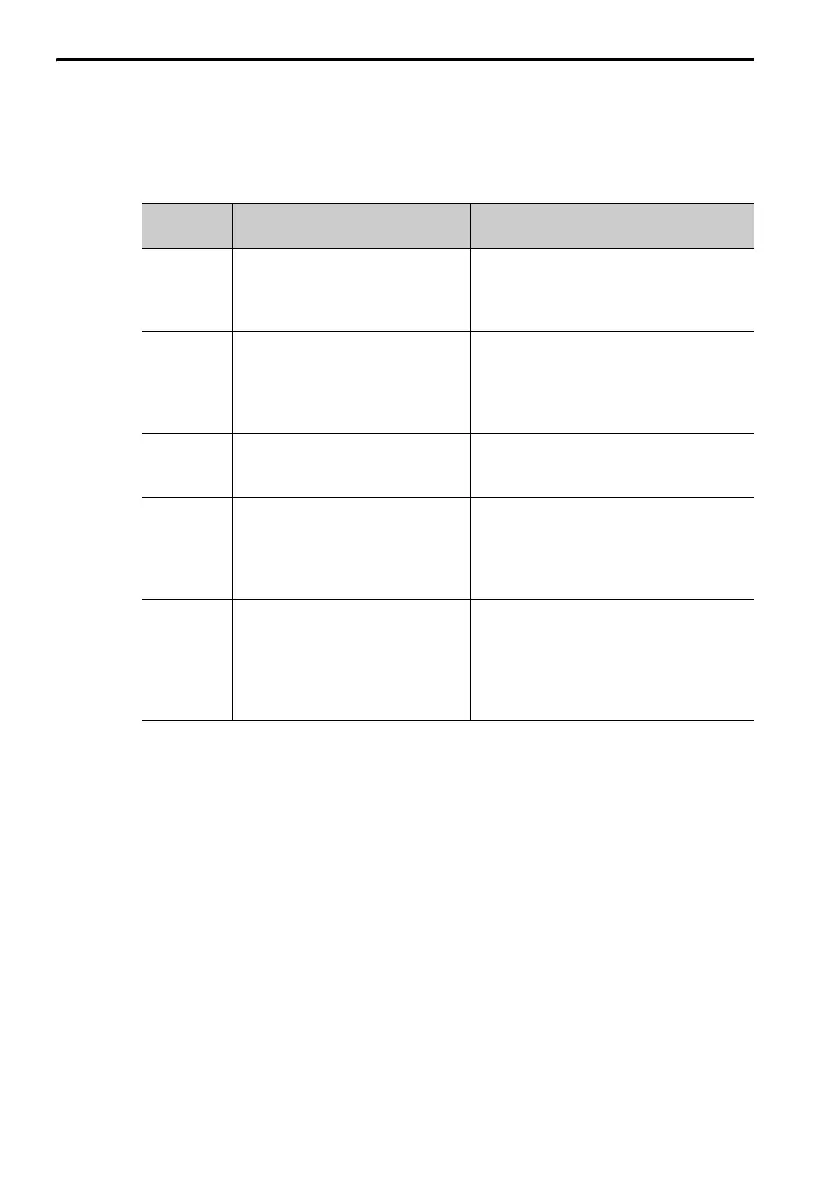

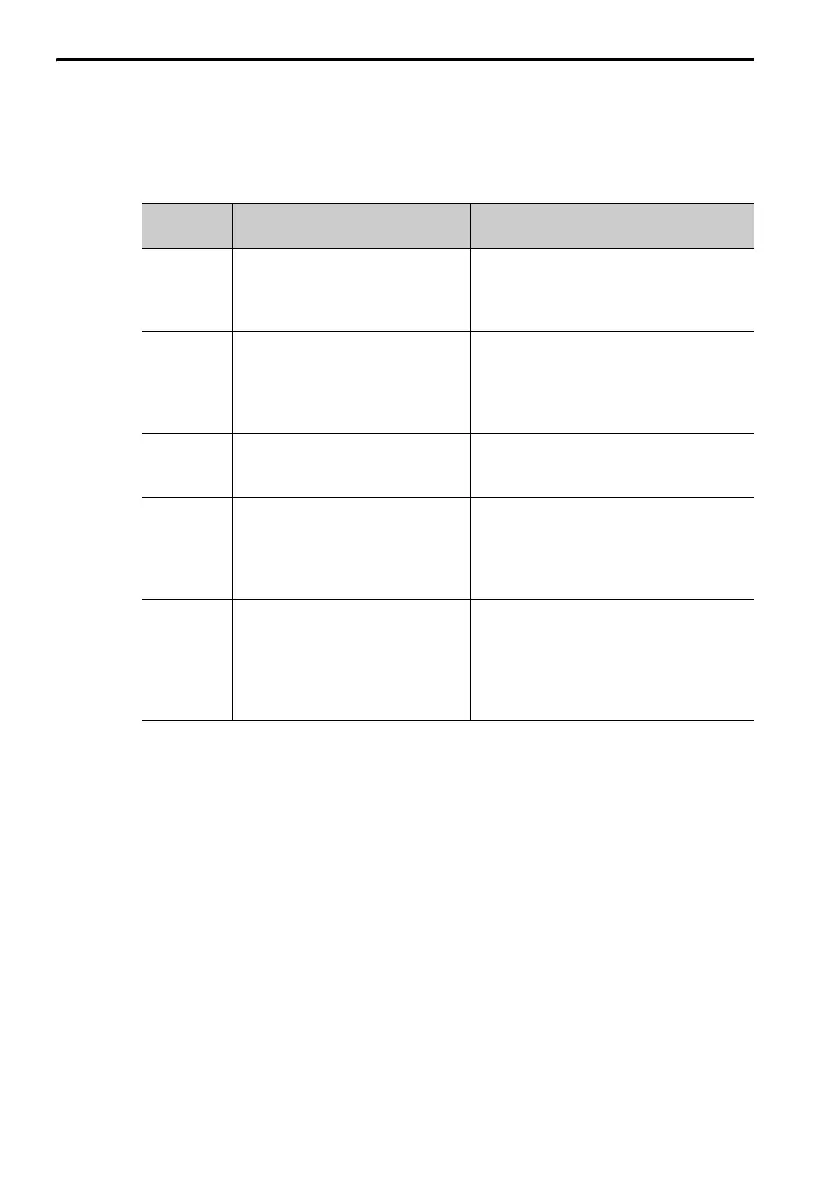

Errors during Calculation of Moment of Inertia

The following table gives the probable causes of errors that may occur

during calculation of the moment of inertia (Jcalc = ON), along with cor-

rective actions for the errors.

Error

Display

Probable Cause Corrective Action

Err1

The SERVOPACK started cal-

culating the moment of inertia

but the calculation was not

completed.

• Increase the setting of Pn100

(Speed Loop Gain).

• Increase the setting of the stroke.

Err2

The moment of inertia fluctu-

ated greatly and did not con-

verge within 10 tries.

Calculate the moment of inertia

based on the machine specifica-

tions, set the value in Pn103, and

execute advanced autotuning with

the Jcalc set to OFF.

Err3

Low-frequency vibration was

detected.

Double the setting of Pn324

(Moment of Inertia Calculation

Starting Level).

Err4 The torque limit was reached.

• If you are using the torque limit,

increase the torque limit.

• Double the setting of Pn324

(Moment of Inertia Calculation

Starting Level).

Err5

The speed control section

changed to proportional con-

trol during calculation of the

moment of inertia, e.g., the /

P-CON (Proportional Control)

signal was input.

Use PI control when calculating the

moment of inertia.

Loading...

Loading...