653D SYSTEMS, INC.

UNLOADING A PLATE

Introduction

Caution : always use appropriate safetey equipment when operating the printer. Personal Protective

Equipment (PPE) must be used to protect the user against health or safety risks during working tasks.

Wear disposable rubber gloves, anti-static coverall, anti-static safety shoes and safety glass. Wear

disposable dust mask rated FFP3 or N99 level protection at minimum ; we recommend the use of powered

air-purifying respirator.

WARNING : REACTIVE POWDER

THE MANUFACTURING CHAMBER MUST BE INERT BEFORE POWDER MANIPULATION (O

2

LEVEL 1%

MAXIMUM).

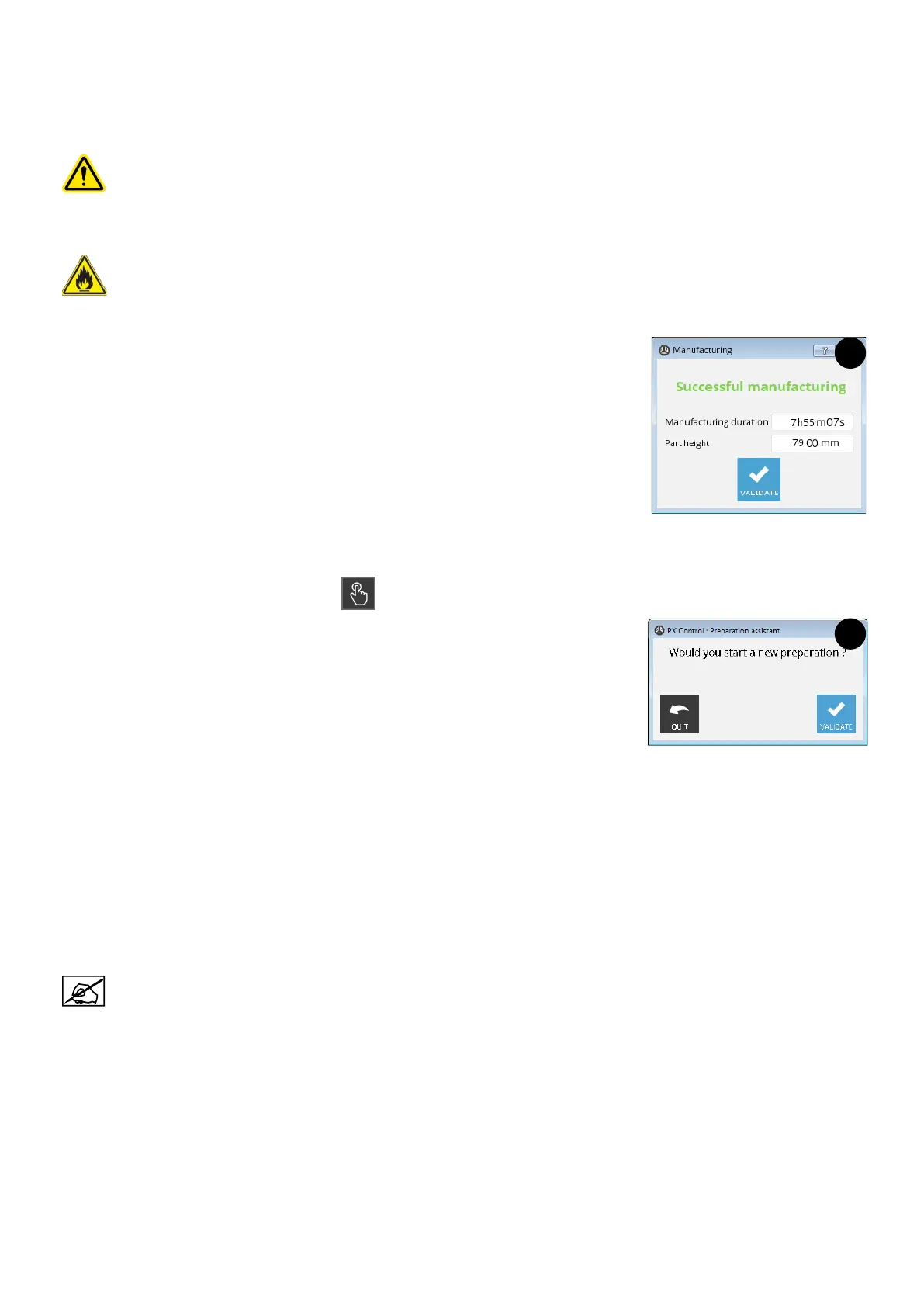

• When a job is complete, the control panel will display the job time and the part height. Proceed as indicated below:

1. Click on Validate to quit the end job window (1).

• The plate unloading is performed through the Plate Unloading cycle, corresponding to the step 2 of the Preparation

Assistant. Proceed as indicated below:

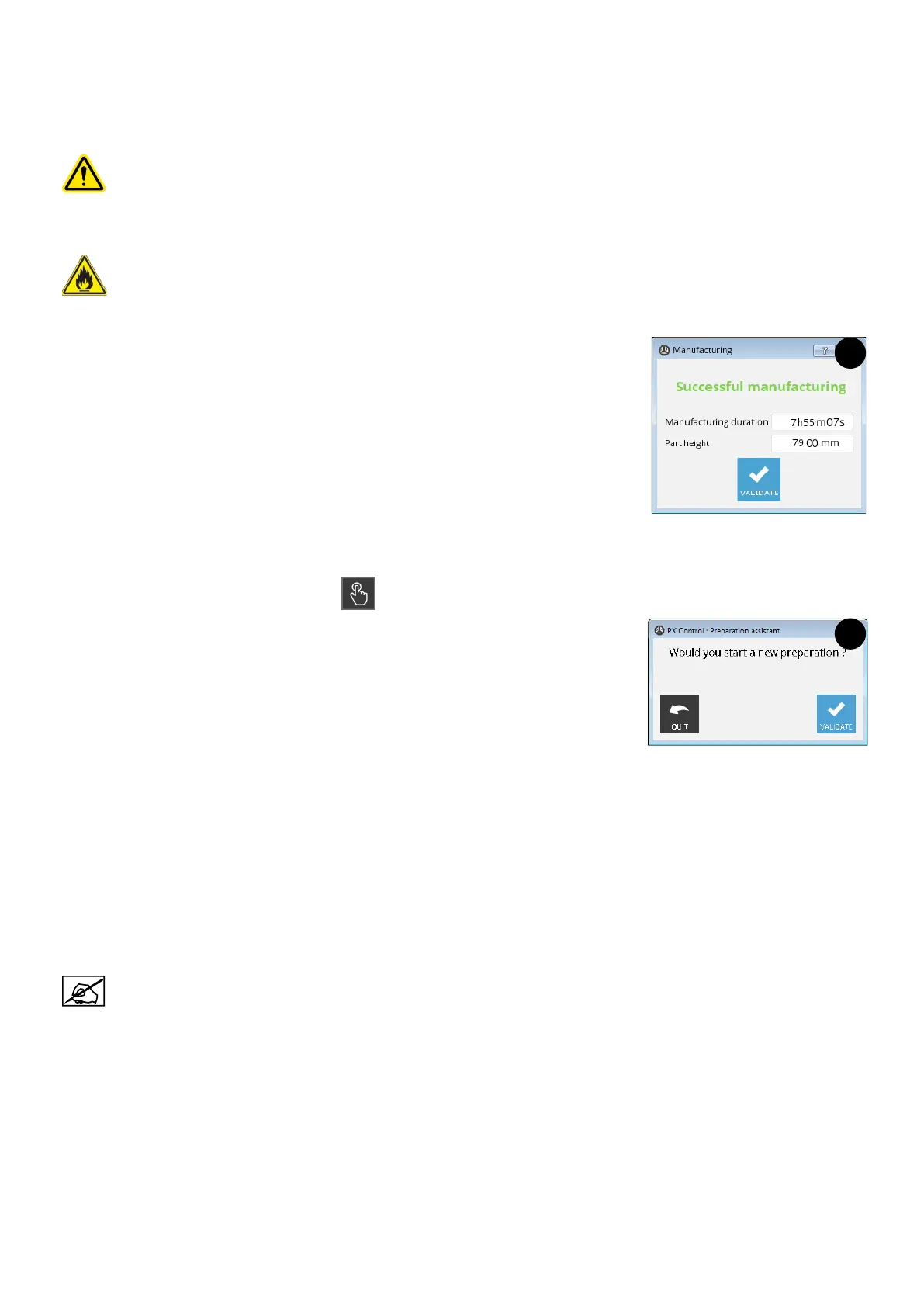

1. Click on the Preparation Menu button

.

2. Click on Validate to conrm (2).

3. Follow the Preparation Assistant up to the step#2 Plate Unloading.

• The plate unloading cycle includes the following phases:

• Sintered plate cleaning.

• Manufacturing chamber cleaning.

• Powder cans removal.

Sintered plate cleaning

Operations described below complement and follow on from the Preparation Assistant "Step 2 : Plate unloading" on page

36.

1. Start the Plate Unloading cycle (see "Step 2 : Plate unloading" on page 36).

The following steps are displayed on the corresponding cycle.

2. Automatic cycles are performed:

• the sintering piston rises and build platform is unclamped,

• the airlock rotates to OPEN position.

3. Unlock the doors of the machine and open them.

4. Open the airlock door.

5. Put the natural ber brush on the airlock, and close the airlock door.

6. Only for powders oxidizable materials, purge the airlock for 5 minutes.

7. Rotate the airlock to CLOSE position.

8. Put the gloves and open the glove doors.

1

2

Loading...

Loading...