583D SYSTEMS, INC.

Plate preparation and loading

Operations described below complement and follow on from the Preparation Assistant "Step 3 : Plate loading" on page

37.

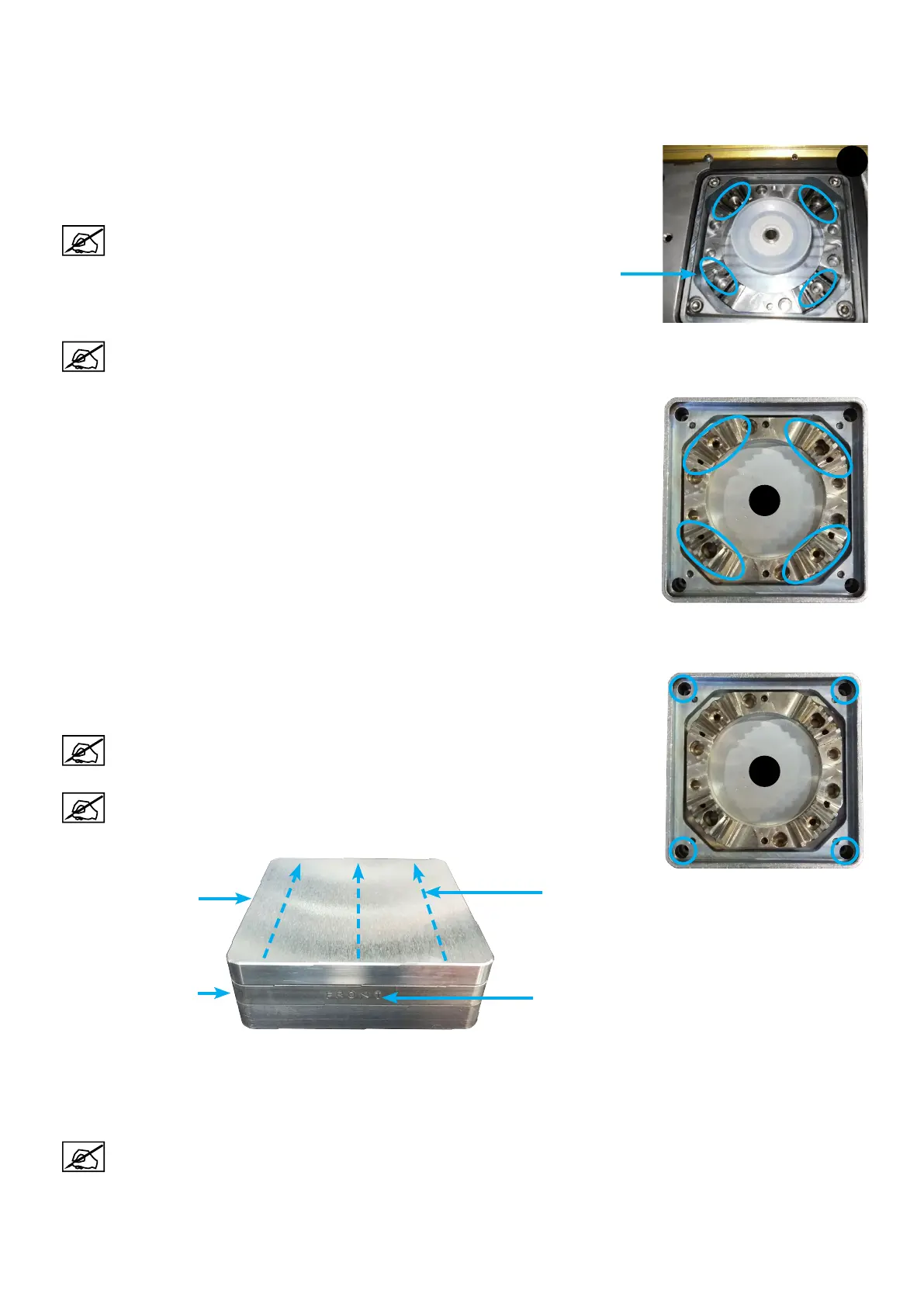

1. Check that the Hirth clamping system of the sintering piston is clean (1). If not, clean it

with the use of a natural ber brush.

Clean the Hirth gear teeth thoroughly, as they will position the sintering

plate + the plate support in the machine.

The manufacturing chamber cleaning step (see "Unloading a plate" on page 65) includes the cleaning of

the Hirth clamping system. This control is to make sure the clamping system will operate correctly.

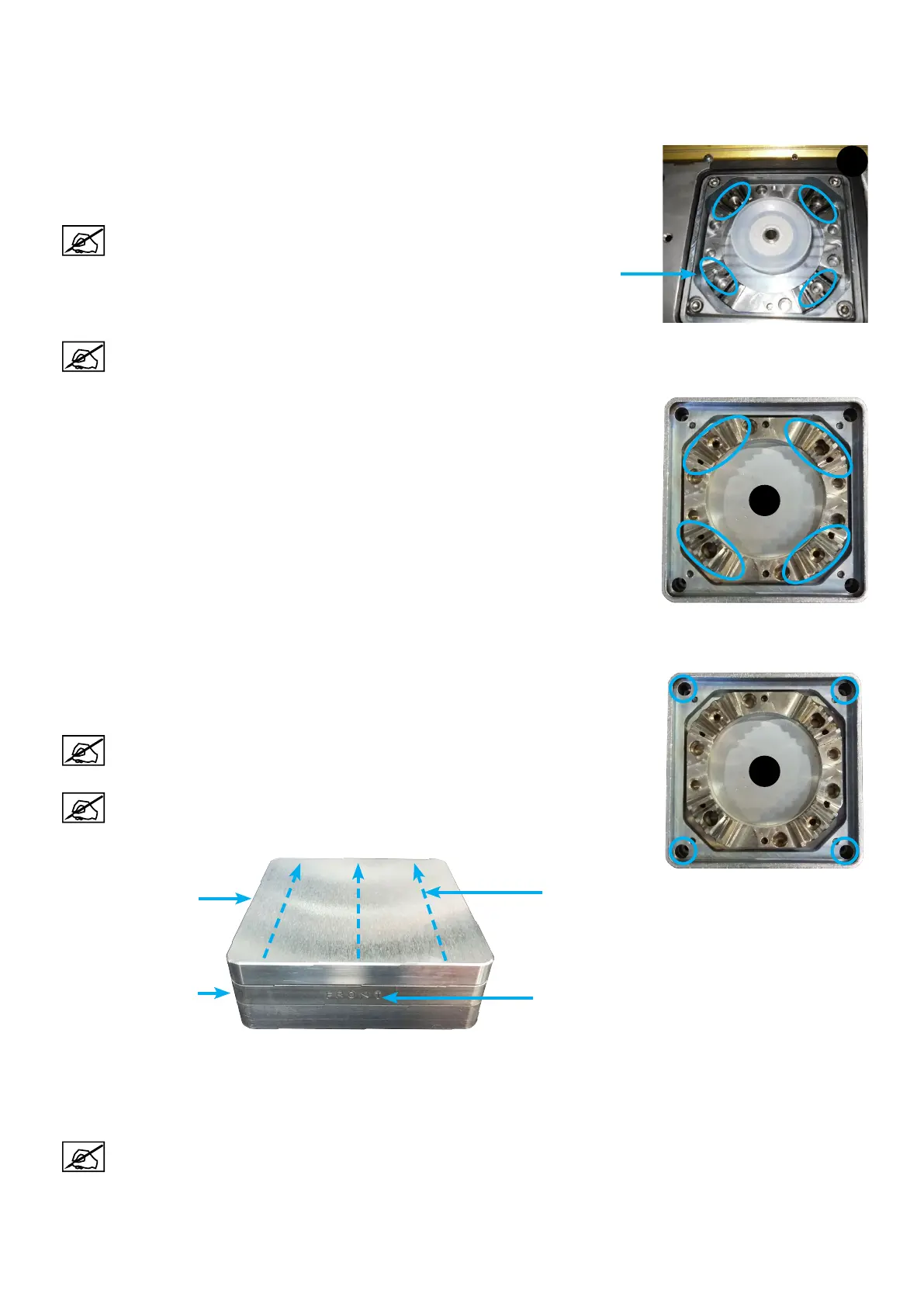

2. Clean the bottom part of the plate support (2).

3. Degrease the upper face of the plate support and clean it with dry paper towel.

4. Attach a sintering plate to the plate support (3) using the 4 screws. The whole will be

called build platform.

Plate support : make sure to position the plate support so that the

“FRONT” marked symbol is front of the operator.

Sintering plate : make sure to position the sintering plate on the plate

support as indicated on the picture. The grinding lines of the sintering

plate must be on the same direction than the operator.

5. Degrease the upper face of the sintering plate and clean it with dry paper towel.

To avoid leaving towel residues on the sintering plate, clean it in the grinding lines direction.

6. Protect the whole against dust by wrapping in paper towels.

2

Sintering plate

Plate support

Grinding lines

“FRONT” symbol

1

Hirth gear

3

Loading...

Loading...