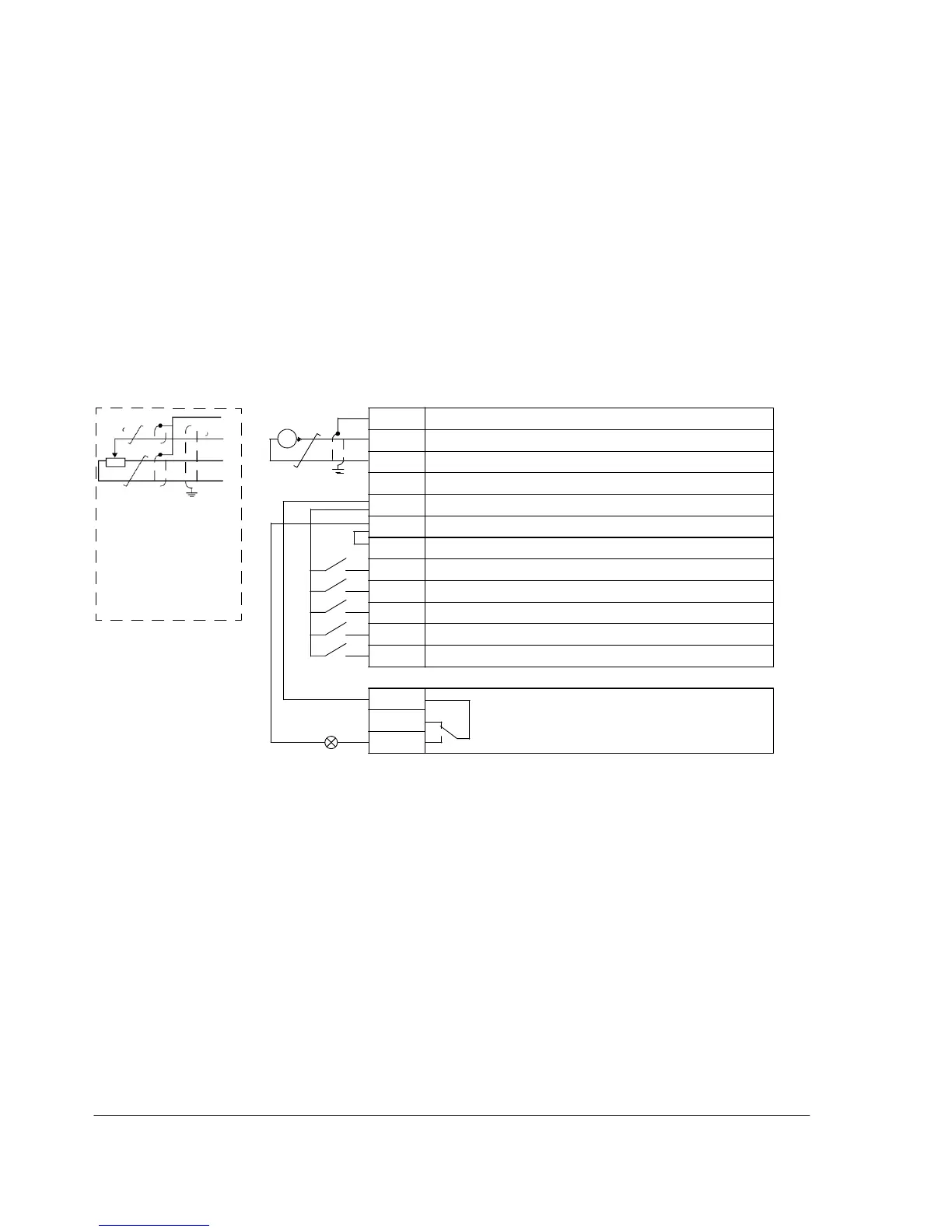

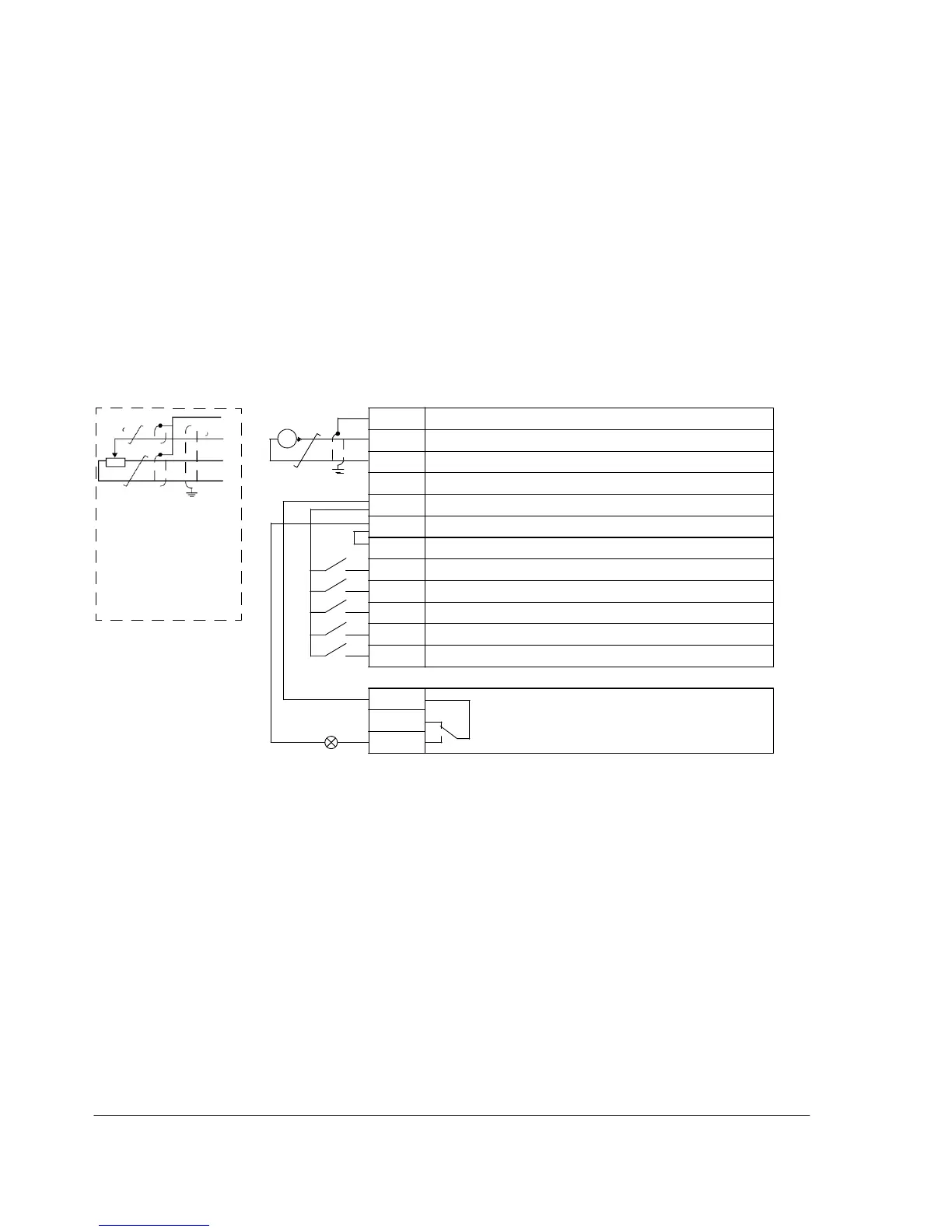

PID control macro

This macro provides parameter settings for closed-loop control systems such as

pressure control, flow control, and so on. Control can also be switched to speed

control using a digital input. To enable the macro, set the value of parameter 9902

APPLIC MACRO to 6 (PID CONTROL).

For the parameter default values, see section Default parameter values with different

macros on page 79. If you use other than the default connections presented below,

see chapter Electrical installation, section I/O terminals on page 44.

Note: Parameter 2108 START INHIBIT must remain in the default setting 0 (OFF).

1…10 kohm

Default I/O

connections

2)

I/O connection

3)

SCR Signal cable shield (screen)

AI Process actual value: 4…20 mA

1)

GND Analog input circuit common

+10V Reference voltage: +10 V DC, max. 10 mA

Alternative connection

for AI1. If used, switch

IU selector to U

(2…10 V voltage

signal).

+24V Auxiliary voltage output: +24 V DC, max. 200 mA

GND Auxiliary voltage output common

COM Digital input common

DI1 Stop (0) / Start (1) (Hand)

DI2 Hand (0) / PID (1) control selection

DI3 Constant speed 1: parameter 1202 CONST SPEED 1

DI4 Run enable

DI5 Stop (0) / Start (1) (PID)

Relay connection

4)

COM Relay output

NC

No fault [Fault (-1)]

NO

1)

Hand: frequency reference comes from the

integrated potentiometer

PID: Process reference comes from the

integrated potentiometer.

2)

360 degree grounding under a clamp.

3)

Tightening torque: 0.22 N·m / 2 lbf·in

4)

Tightening torque: 0.5 N·m / 4.4 lbf·in

Loading...

Loading...