Update notice

12

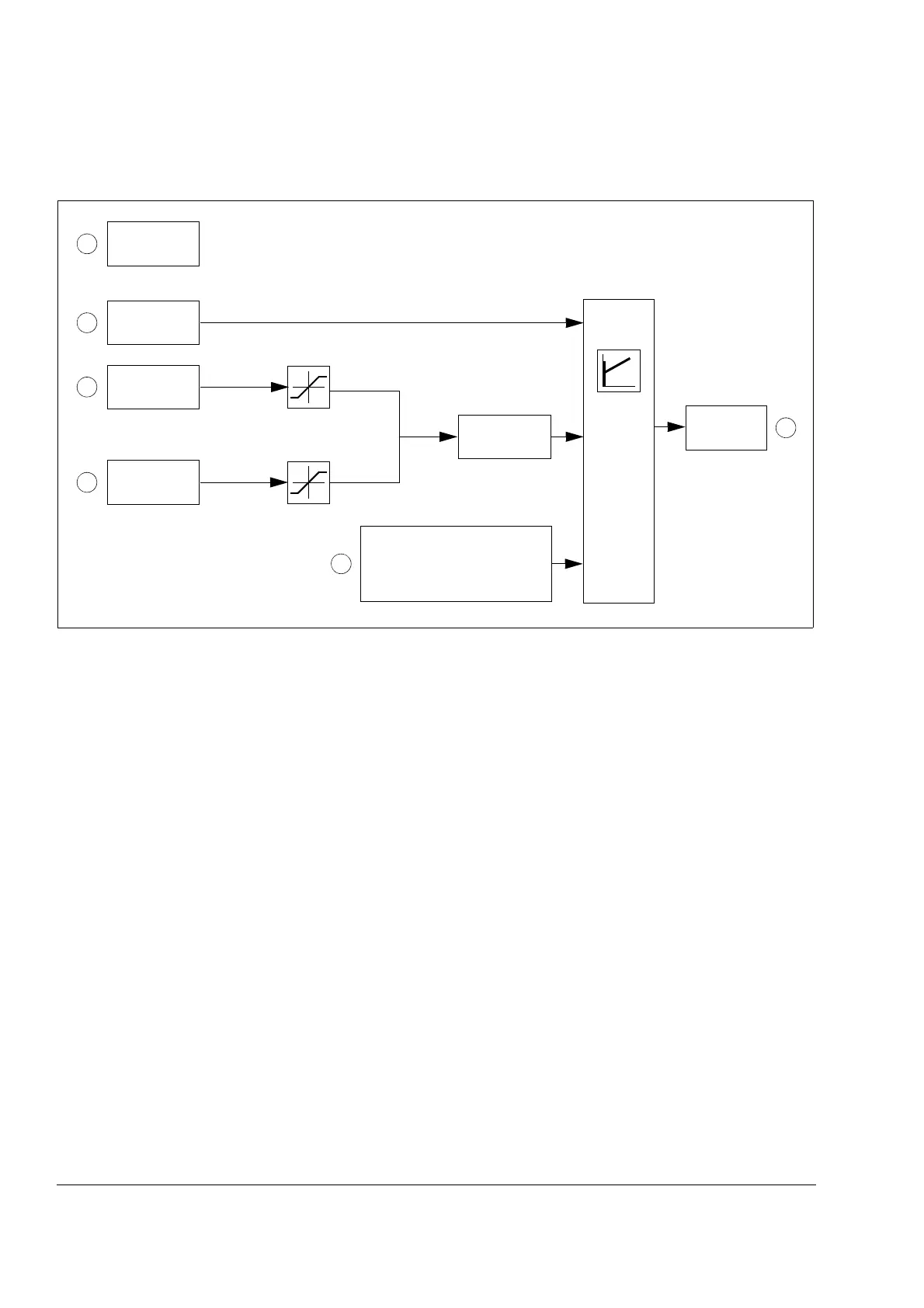

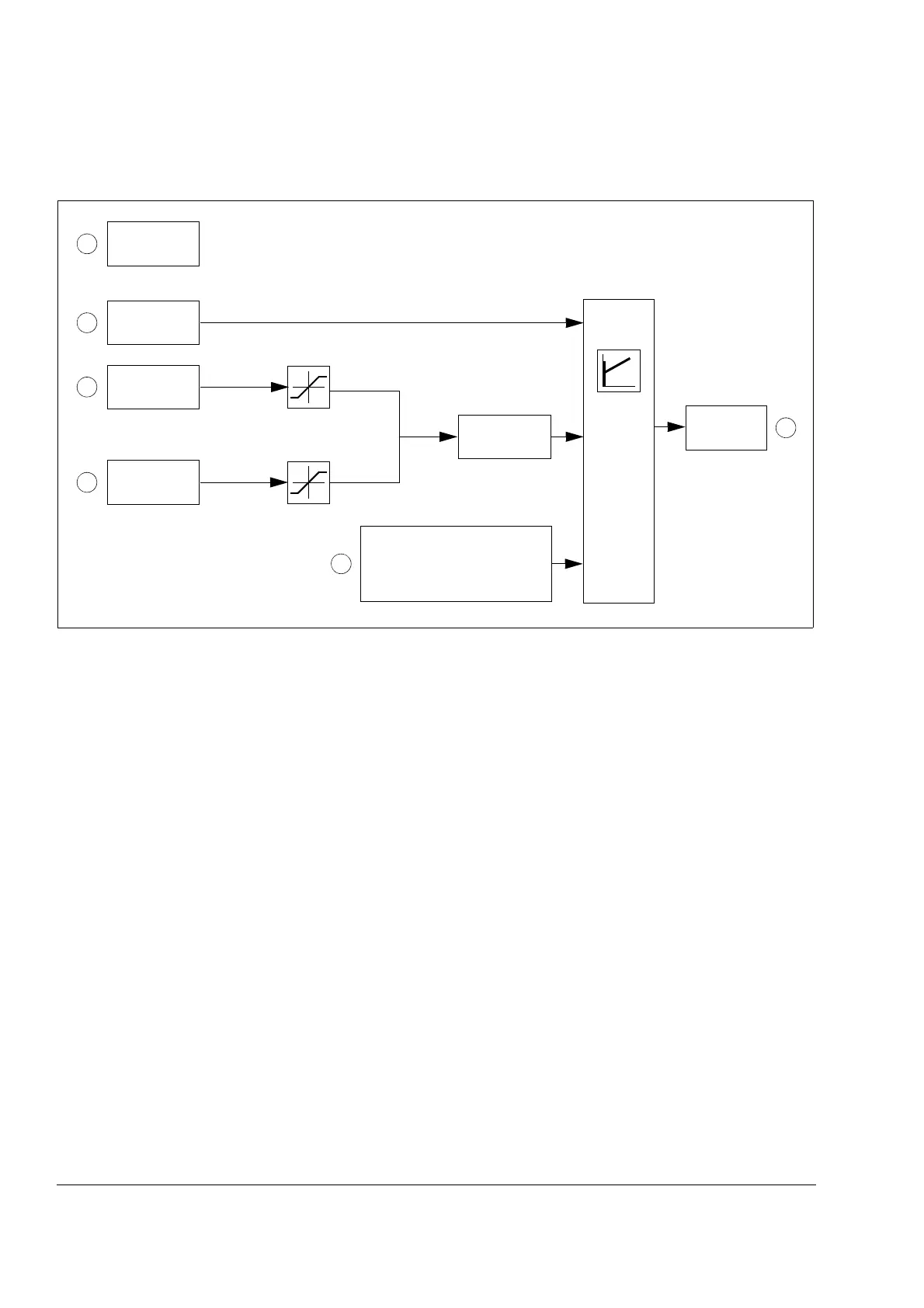

Quick configuration of process control

1. 9902 APPLIC MACRO: Set 9902 APPLICATION MACRO to 6 (PID CONTROL).

2. 4010 SET POINT SEL: Determine the source for the PID reference signal (PID

setpoint) and define its scale (4006 UNITS, 4007 UNIT SCALE).

3. 4014 FBK SEL and 4016 ACT1 INPUT: Select the process actual value

(feedback signal) for the system and configure feedback levels (4018 ACT1

MINUMUM, 4019 ACT1 MAXIMUM).

4. 4017 ACT2 INPUT: If a second feedback is used, configure also this actual value

2 (4020 ACT2 MINIMUM and 4021 ACT2 MAXIMUM).

5. 4001 GAIN, 4002 INTEGRATION TIME, 4003 DERIVATION TIME, 4005 ERROR

VALUE INV: Configure the desired gain, integration time, derivation time and

error value inversion when needed.

6. Activate PID output: Check that 1106 REF2 SELECT is set to 19 (PID1OUT).

4010 SET

POINT SEL

4016 ACT1

INPUT

4017 ACT2

INPUT

4014 FBK

SEL

4001 GAIN

4002 INTEGRATION TIME

4003 DERIVATION TIME

4005 ERROR VALUE INV

Process

PID

PID output

3

4

2

5

6

4019 ACT1 MAXIMUM

4019 ACT1

MAXIMUM

4018 ACT1

MINUMUM

4018 ACT1 MINUMUM

4021 ACT2 MAXIMUM

4020 ACT2 MINUMUM

9902 APPLIC

MACRO

1

Loading...

Loading...