192 Safety functions

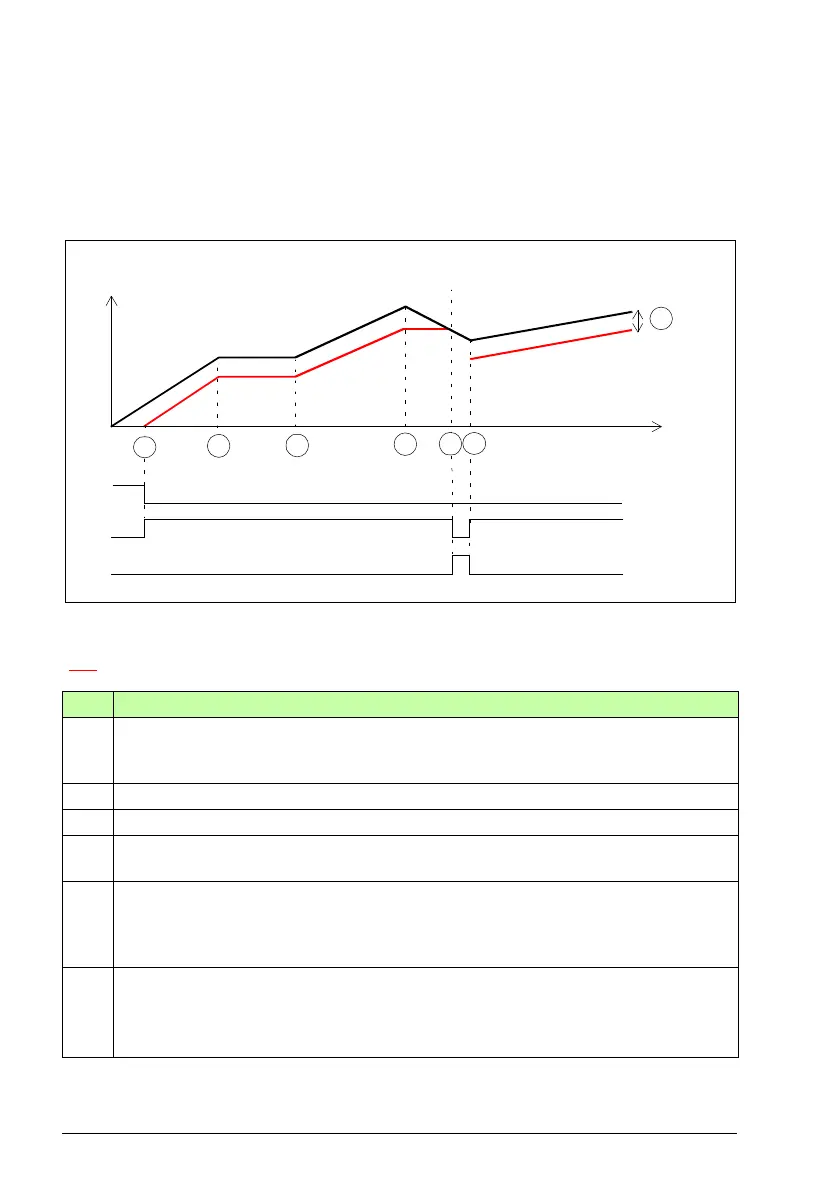

SDI trip limit hits

This applies to SDI trip limit hit situations, that is, when the motor rotates too much to

the forbidden direction while the SDI monitoring is on. The SDI positive function is

used as an example.

Note: This diagram shows the position of the motor shaft (not the motor speed).

A SDI tolerance limit degree (parameter SDI.14): The motor shaft cannot move to the

forbidden direction more than defined with this parameter.

SDI monitoring limit

Step Description

1 The SDI positive request is received (for example, from the I/O) and the FSO starts the

SDI monitoring. The SDI active indication goes on. The motor rotates to the correct

direction (in this case, positive).

2 The motor stops.

3 The motor starts to rotate again (into the positive direction).

4 The rotation direction of the motor changes to the forbidden (negative) direction. The

FSO locks the SDI tolerance limit (A) into its current position.

5 The SDI tolerance limit (A) is reached. The FSO stops the SDI monitoring and activates

the SSE function and the motor coasts to a stop. The SDI indication goes off. The SSE

indication goes on. See section Safe stop emergency (SSE) on page 106 for more

information on how to configure the SSE function.

6 The motor has stopped. The SSE function is completed and the FSO starts the SDI

monitoring. The SDI active indication goes on and the SSE indication goes off.

When the motor starts to rotate again (into the correct direction), the SDI monitoring

continues with the original SDI tolerance limit (A).

SDI state &

indication

SDI request

Motor shaft

position

Time

1

2

4

SSE state &

indication

A

3

5

6

- -> Safe stop emergency (SSE)

Loading...

Loading...