NoteAction

Fit 14 of the 16 attachment screws before the

arm system is completely lowered.

11

This is done in order to be able to attach all

screws into the threads correctly.

Replace the guide pins with the remaining

attachment screws and secure the complete

arm system to the base with its attachment

screws and washers.

12

Lower the arm system completely.13

Tightening torque:

• 120 Nm.

Secure the complete arm system with its at-

tachment screws.

14

See Replacing cable harness, lower end

(axes 1-3) on page 147.

Refit the cable harness in the base and the

frame.

15

See Replacing motor, axis 1 on page 285.Refit the axis 1 motor.16

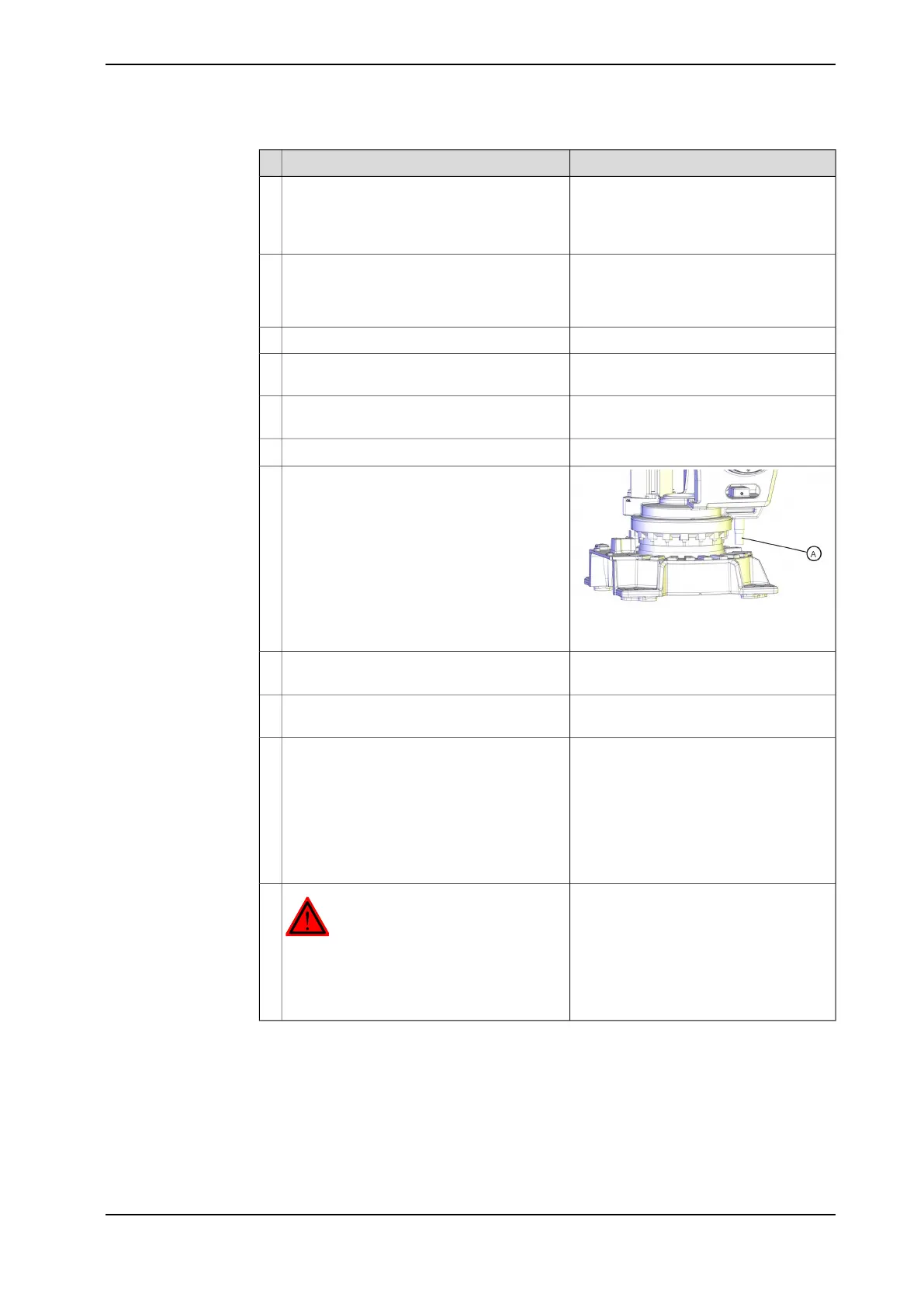

xx1000001302

Refit the mechanical stop pin to the frame.17

A: Mechanical stop pin

See Performing a leak-down test on

page 140.

Perform a leak-down test of the axis 1 gear-

box.

18

See Changing oil, axis-1 gearbox on

page 122.

Refill the axis 1 gearbox with lubricating oil.19

Pendulum Calibration is described in

Operating manual - Calibration Pendulum,

enclosed with the calibration tools.

Recalibrate the robot.20

Axis Calibration is described in Calibrat-

ing with Axis Calibration method on

page 357.

General calibration information is included

in section Calibration on page 347.

DANGER

Make sure all safety requirements are met

when performing the first test run. These are

further detailed in the section First test run

may cause injury or damage on page 26.

21

Product manual - IRB 460 181

3HAC039842-001 Revision: P

© Copyright 2012-2018 ABB. All rights reserved.

4 Repair

4.3.5 Replacing the base, including axis 1 gearbox

Continued

Loading...

Loading...