NoteAction

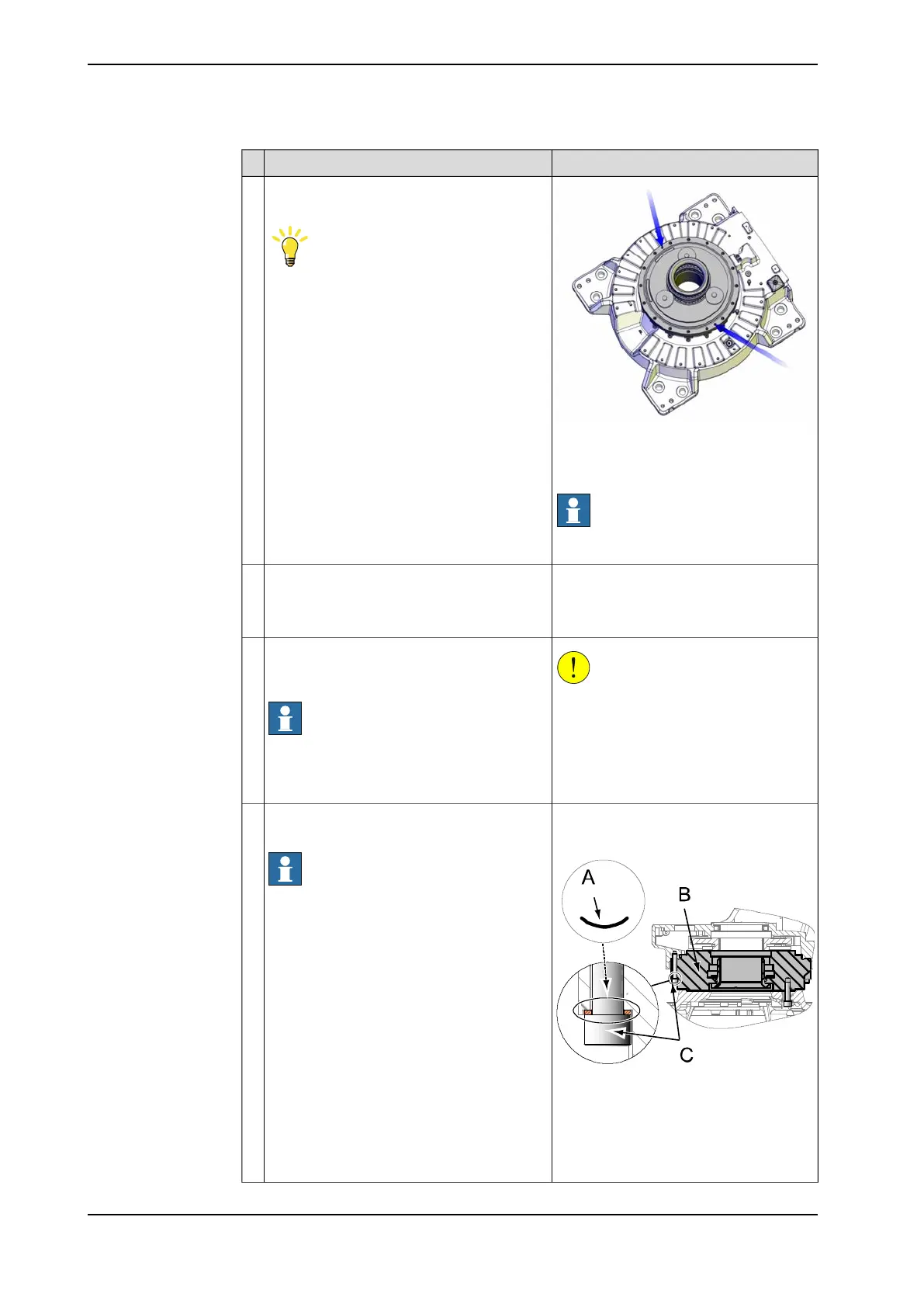

xx1100000257

Fit two guide pins in the holes in the axis 1

gearbox, shown in the figure.

Tip

In order to make refitting easier it is recom-

mended to use two guide pins of different

lengths. Notice that longer guide pins than

140 mm will not be possible to remove after

refitting because of lack of space.

7

Dimension is specified in Required

equipment on page 174.

Note

Always use guide pins in pairs.

Look through the empty mounting hole of the

axis 1 motor to assist in aligning the as-

sembly during refitting of the complete arm

system.

8

CAUTION

This is a complex task to be performed

with utmost care in order to avoid injury

or damage!

Use a crank to turn the gearbox in order

to find the right position for the holes.

Lower the complete arm system with guid-

ance from the guide pins previously fitted to

the axis 1 gearbox.

Note

The refitting must be made completely level!

Make sure the roundslings are adjusted prior

to refitting the arm system.

9

Reused screws can be used providing

they are lubricated as described in Screw

joints on page 379.

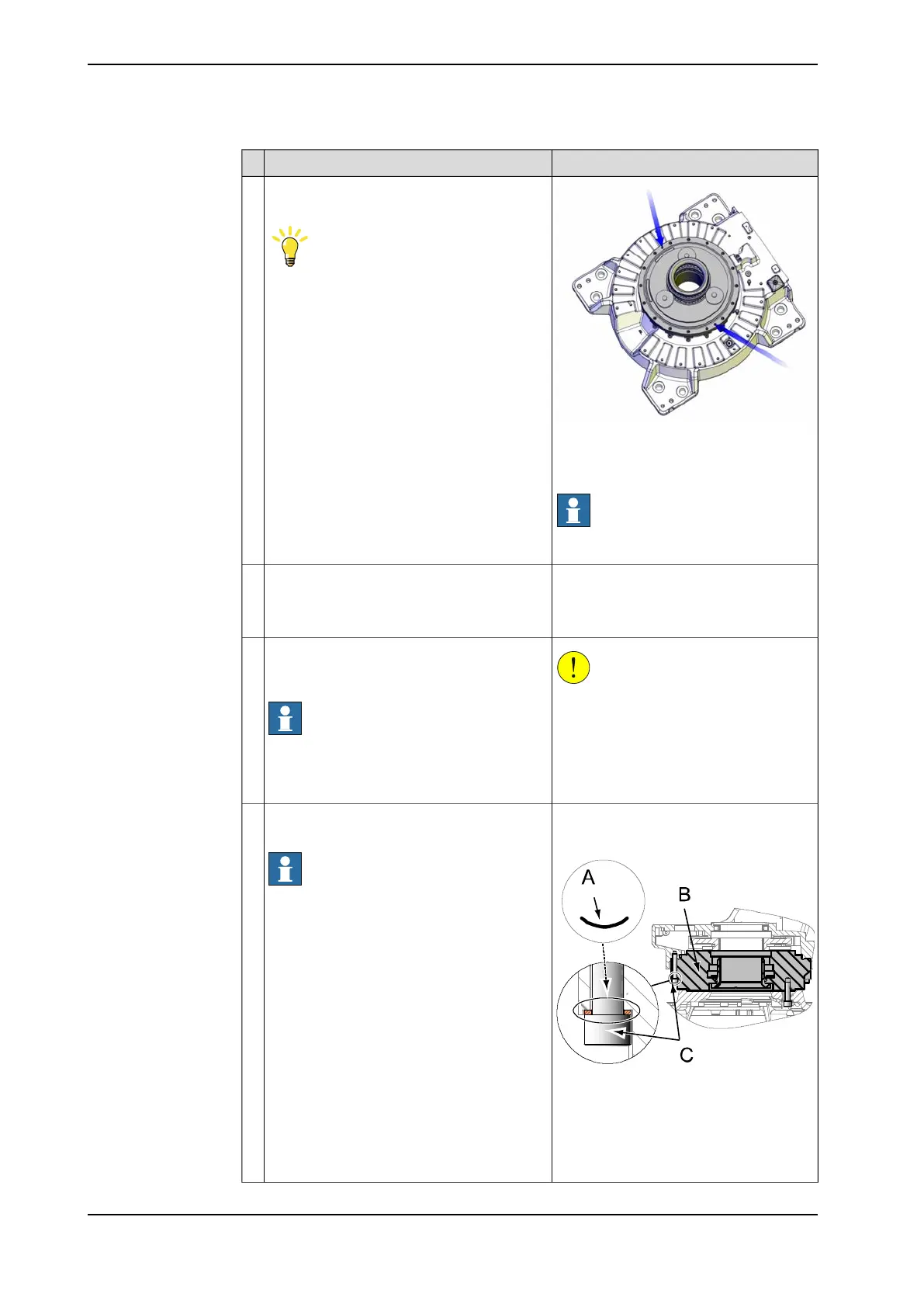

xx0600003070

Place the serrated lock washers on the attach-

ment screws.

Note

Check that the serrated lock washers are

turned the correct way. See figure!

10

Parts:

A Serrated lock washer (24 pcs)

B Axis 1 gearbox

C Attachment screws M12x110 qual-

ity 12.9 gleitmo (24 pcs)

Continues on next page

180 Product manual - IRB 460

3HAC039842-001 Revision: P

© Copyright 2012-2018 ABB. All rights reserved.

4 Repair

4.3.5 Replacing the base, including axis 1 gearbox

Continued

Loading...

Loading...