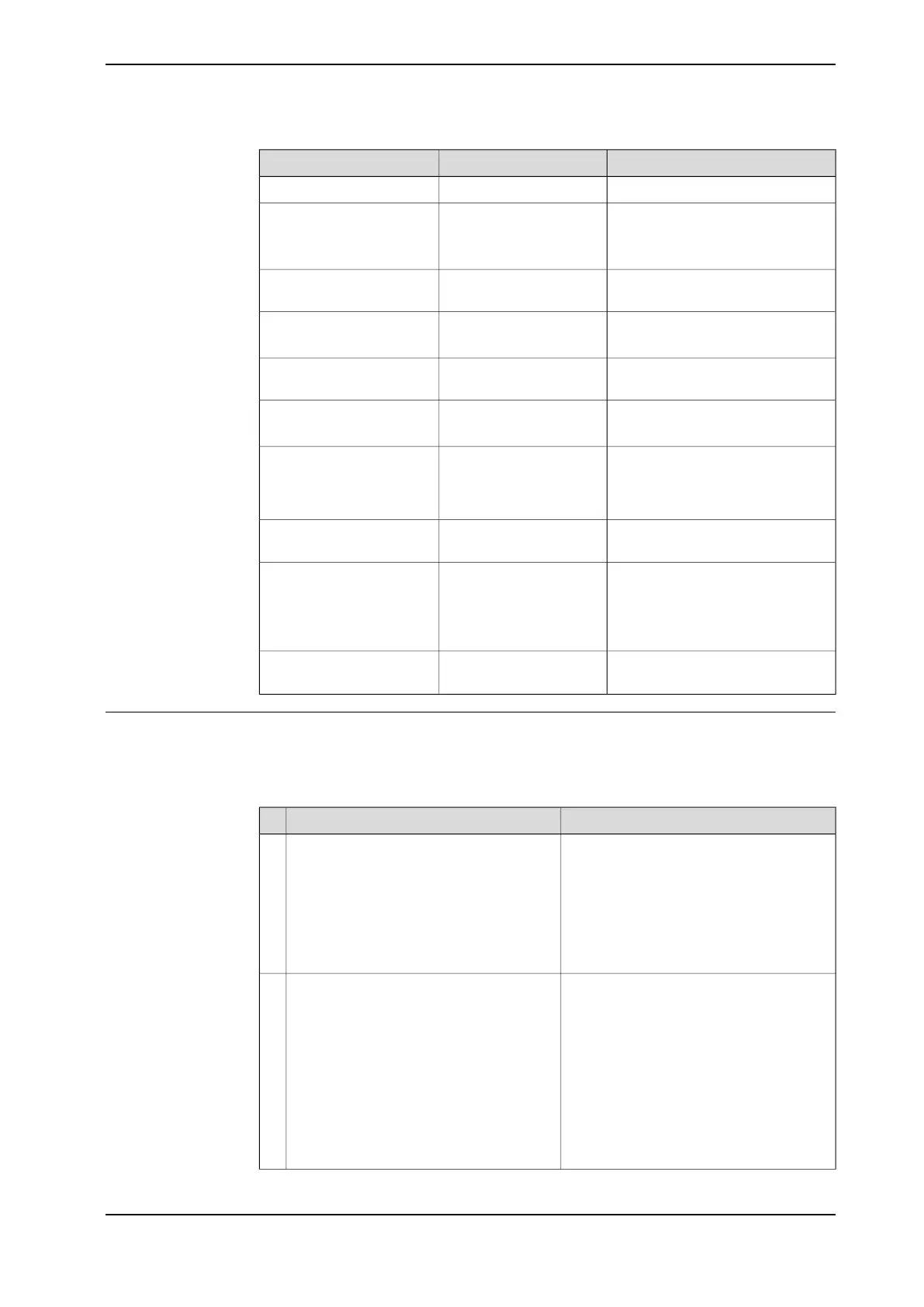

NoteArt. no.Equipment, etc.

For lubricating the o-ring.3HAB3537-1Grease

M10x1503HAC13120-2Guide pins

For guiding the motor.

Guide pins are to be used in pairs!

3HAC14586-1Lifting accessory, motor

axes 2-3

M16x90-Lock screw

For securing the lower arm.

Used to reach the attachment

screws for the motor.

3HAC023760-001Bits extension

24 VDC, 1.5 A-Power supply

For releasing the brakes.

Used to rotate the motor pinion

when mating it to the gear, when

brakes are released with 24 VDC

power supply.

Rotation tool

Content is defined in section

Standard tools on page 383.

Standard toolkit

These procedures include refer-

ences to the tools required.

Other tools and procedures

may be required. See refer-

ences to these procedures

in the step-by-step instruc-

tions below.

See chapter Circuit diagrams on

page 391.

Circuit diagram

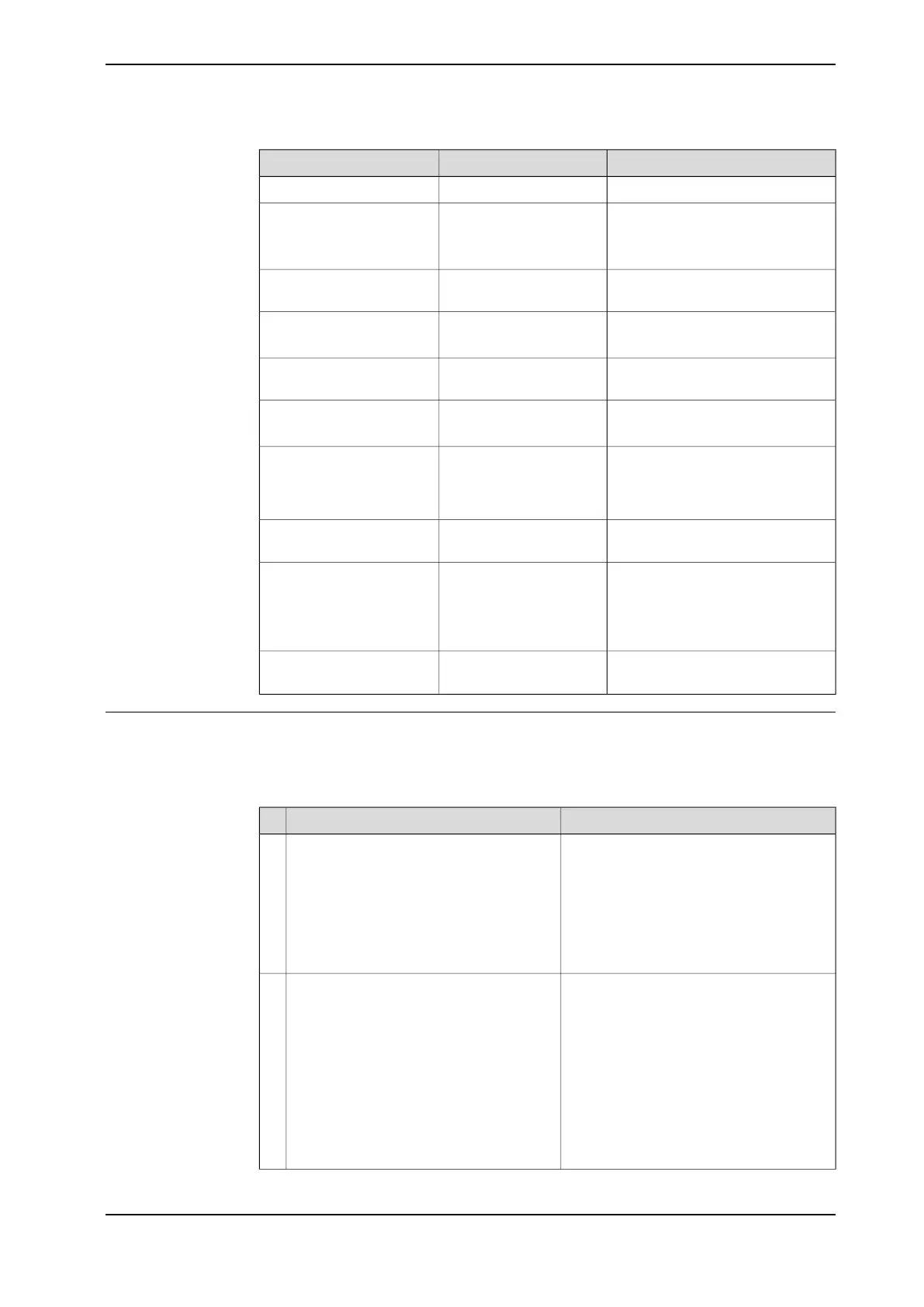

Deciding calibration routine

Decide which calibration routine to be used, based on the information in the table.

Depending on which routine is chosen, action might be required prior to beginning

the repair work of the robot, see the table.

NoteAction

Decide which calibration routine to use for

calibrating the robot.

• Reference calibration. External cable

packages (DressPack) and tools can

stay fitted on the robot.

• Fine calibration. All external cable

packages (DressPack) and tools

must be removed from the robot.

1

Follow the instructions given in the refer-

ence calibration routine on the FlexPendant

to create reference values.

If the robot is to be calibrated with refer-

ence calibration:

Find previous reference values for the axis

or create new reference values. These val-

ues are to be used after the repair proced-

ure is completed, for calibration of the ro-

bot.

Creating new values requires possibility to

move the robot.

Read more about reference calibration for

Axis Calibration in Reference calibration

routine on page 358.If no previous reference values exist, and

no new reference values can be created,

then reference calibration is not possible.

Read more about reference calibration for

Pendulum Calibration in Operating manu-

al - Calibration Pendulum.

Continues on next page

Product manual - IRB 460 295

3HAC039842-001 Revision: P

© Copyright 2012-2018 ABB. All rights reserved.

4 Repair

4.5.2 Replacing motors, axes 2 and 3

Continued

Loading...

Loading...