86 Maintaining Your GC

5 Maintaining the Purged Packed Inlet

5

Tighten the inlet column nut 1/4 turn with a wrench.

6 After conditioning, remove the column from the inlet.

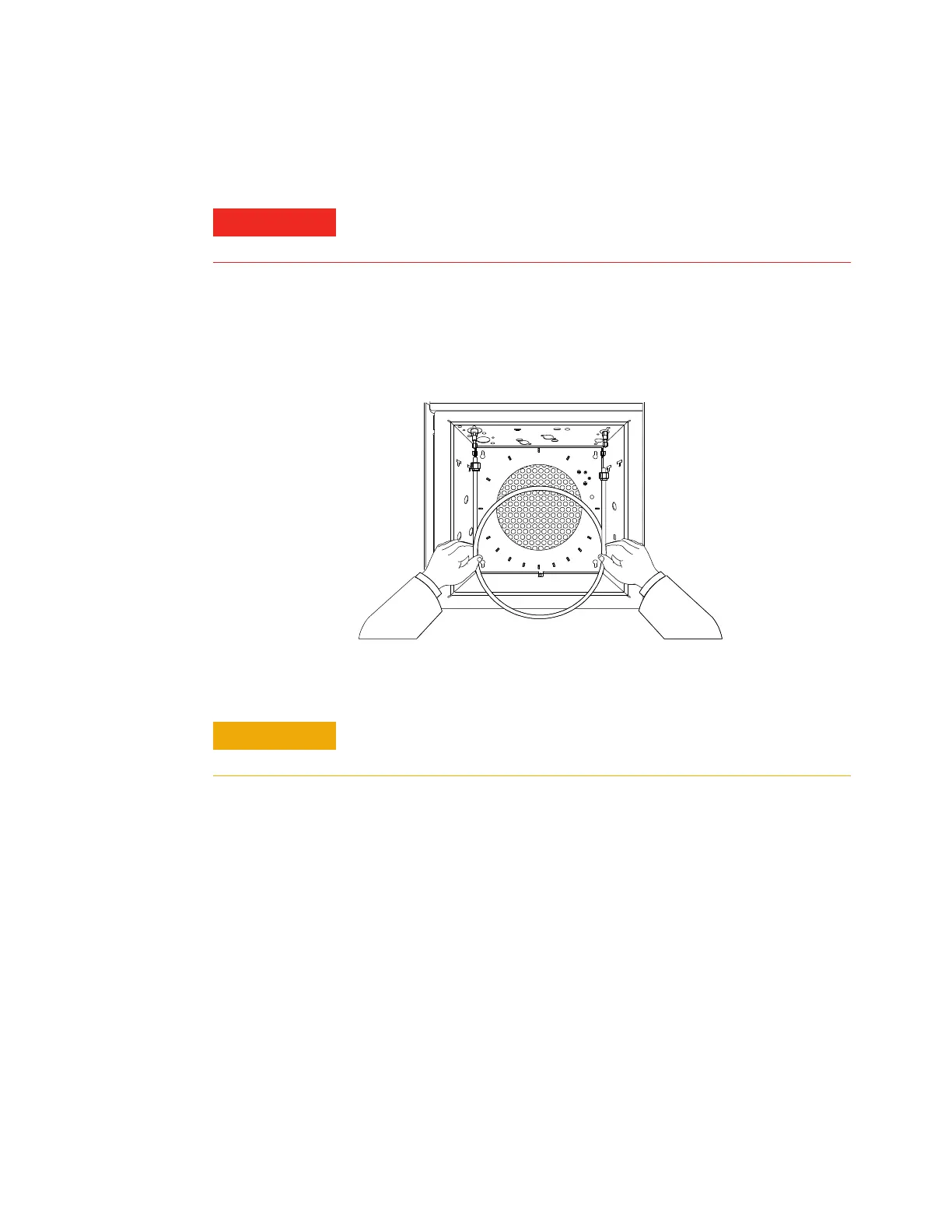

7 Simultaneously insert the column into the inlet and detector

fittings but do not force it. It may be necessary to start the long

end of the column in the inlet at an angle to clear the oven floor.

8 Withdraw the column 1 to 2 mm from both the inlet and

detector. Finger-tighten both column nuts.

9 Tighten both column nuts 1/4 turn with a wrench.

10 Configure the new packed column (make sure either column

length or diameter is zero).

11 Establish a flow of carrier gas and purge as recommended by

the packing manufacturer. Generally:

• 20 to 30 mL/min for 2-mm id glass or 1/8-inch od metal

columns

• 50 to 60 mL/min for 4-mm id glass or 1/4-inch od metal

columns

12 Restore the analytical method.

• For NPD, immediately set the bead voltage to 0.0.

13 After the GC becomes ready, wait 10 minutes then ignite the

detector flame or adjust offset on the NPD bead.

WARNING

Do not use hydrogen as the carrier for conditioning! It could vent

into the oven and present an explosion hazard.

CAUTION

Overtightening the column nut or forcing it to bottom in either the

inlet or detector may shatter the column.

Loading...

Loading...