104

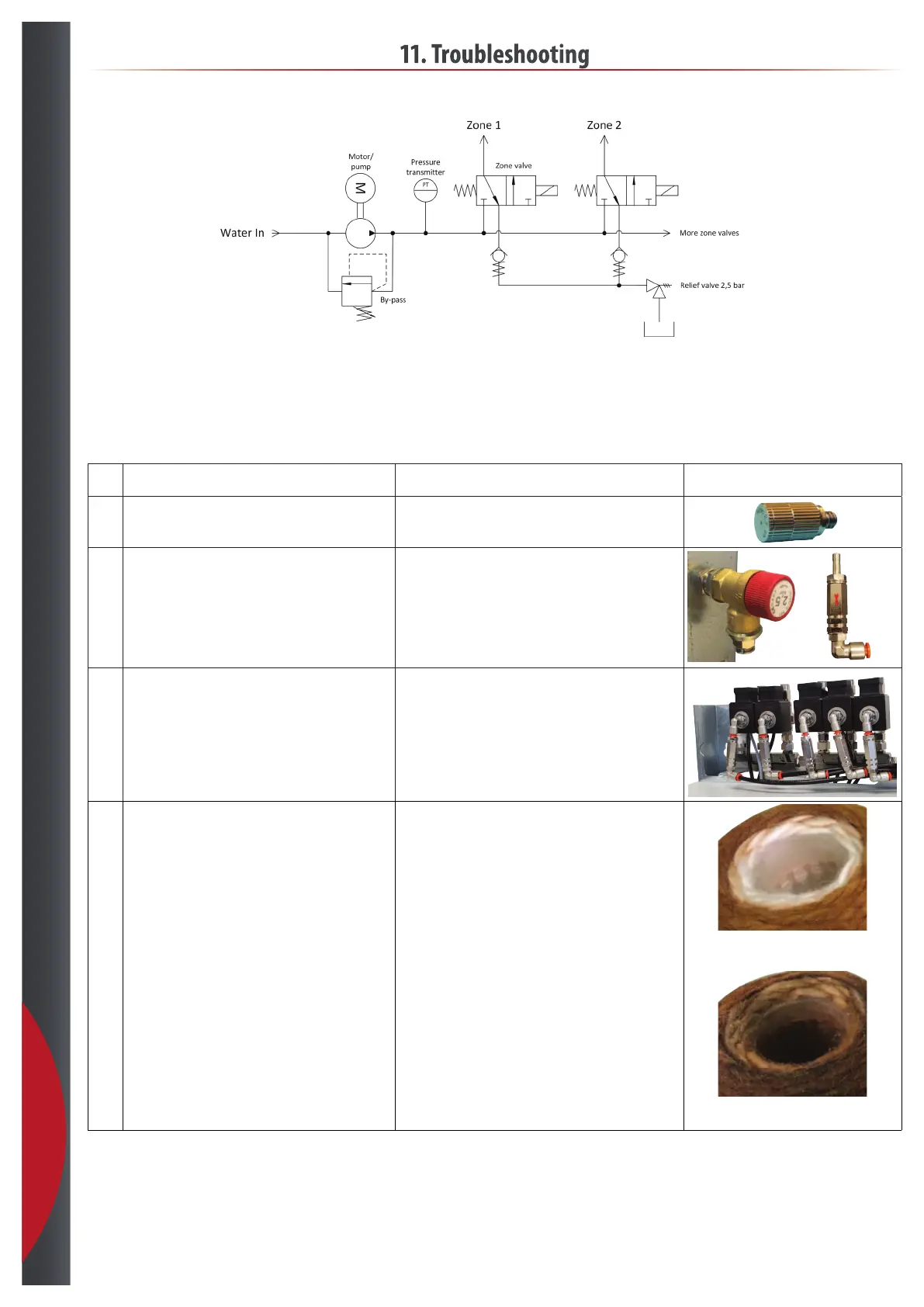

11. Troubleshooting

Nozzles dripping

Fault

code: Cause Solution

101

1. Air in system after service or rst startup.

2. If it is only a few nozzles it the zone that has a problem, it is

typically the nozzle. If it is several in same zone, see code 102.

1. Problem should eliminate itself after few hours

2. Replace the nozzle if the problem Is only with a few, or move to 102.

102

1. Non return valve is leaking or blocked:

a. Blocked valve cause the pressure to be relief through the

nozzle, so it spits water each time it stops.

b. Leaking valve causes air in system, and it makes the nozzles

spits or spray uneven at startup.

2. Non return valve is installed incorrect causing the function to

be opposite.

1. Check if the relief valve releases water when a zone is stopping, and

that it stops running after a few sec. Check one zone at the time. If

not replace it.

2. Check the ow direction on the non return valve, all zones, is from

system against drain, look at the “arrow” turn the valve if incorrectly

installed.

103

1. Solenoid valve unable to open correct, causing lack of water

and pressure.

2. Solenoid valve not closing to the zone, causing water leak with

a low ow to the zone/drain.

3. Solenoid valve relief port blocked.

4. Solenoid valve relief port leaking during operation.

1. Stop all other zones, run only the faulty zone to check if it open

correct. Replace Plunger kit, or valve if not

2. Stop all zones. Start them one at the time. When you start the zone

with a fault, the drain ow would stop. If not replace the entire valve.

3. Remove the non return valve to see if the valve can relief now. Is

it can, remove the blockade, or replace non return valve. If it still

cannot relief, replace valve.

4. Replace plunger kit. If that’s not enough, replace valve.

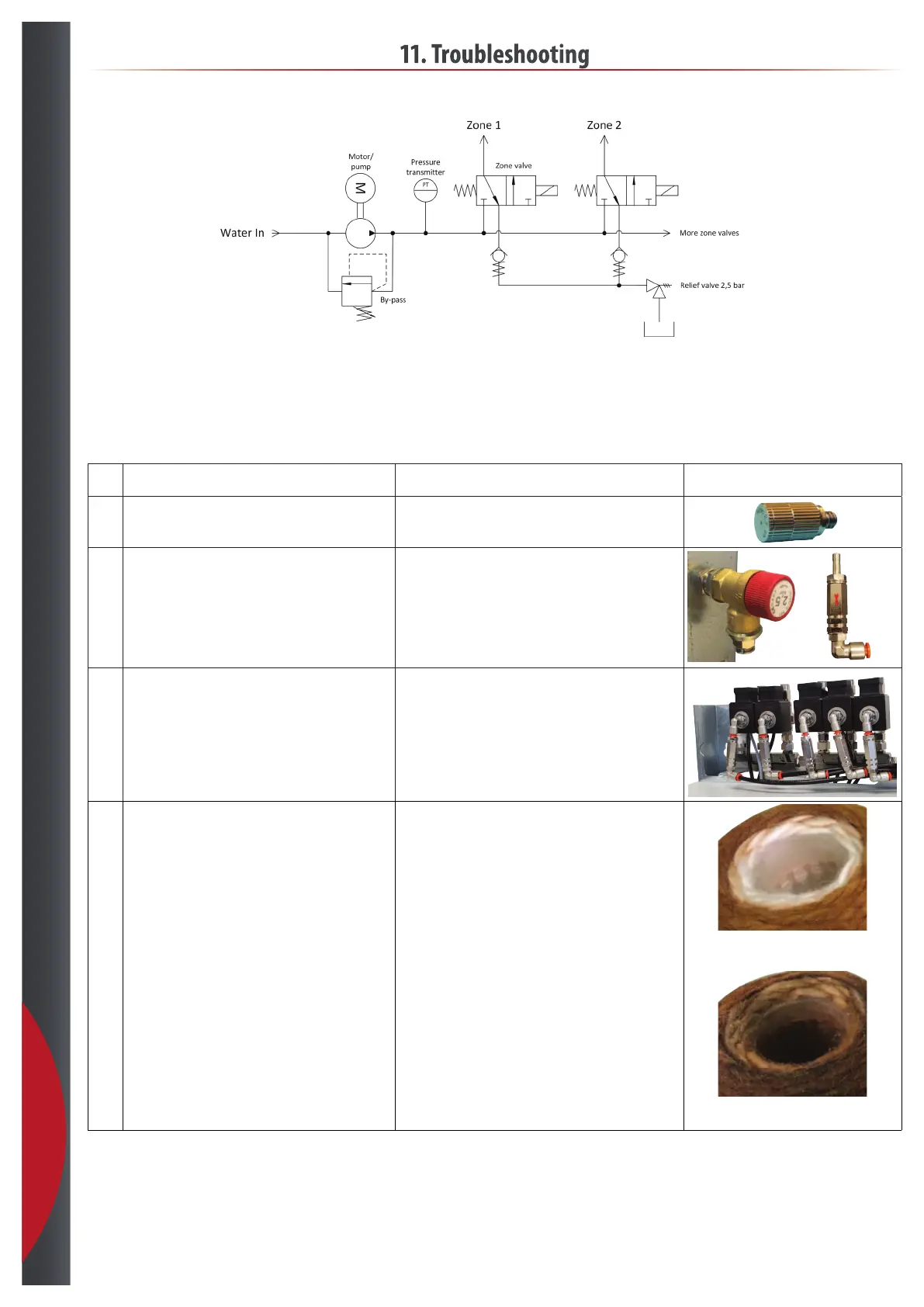

104

1. Defect / blocked lters may cause pass-through which lead to

no ltration, and possible blockade of nozzles

2. Dirt inside hoses from incorrect installation - not sealing hose

ends during installation, leading dirt to ow with the water

during rst startup. Particles bigger than nozzle orice will

block the nozzles.

3. Treated water with conductivity < 5 µS will in extreme cases

make the water act “static” so it sticks to all metal surface,

causing water dripping from the atomizer.

1. Check if the lter is colored on the inside (lter center), replace lters,

and ush hoses proper, before replacing nozzles.

2. Flush the hoses and replace defected nozzles.

3. Adjust atomizer away from metal parts and add nozzle extenders.

• If Adjustment is not enough, control of micro siemens level > 5 µS

is necessary.

OK

Replace

Defect

Change lter more often

201218

Loading...

Loading...