57

8. Service

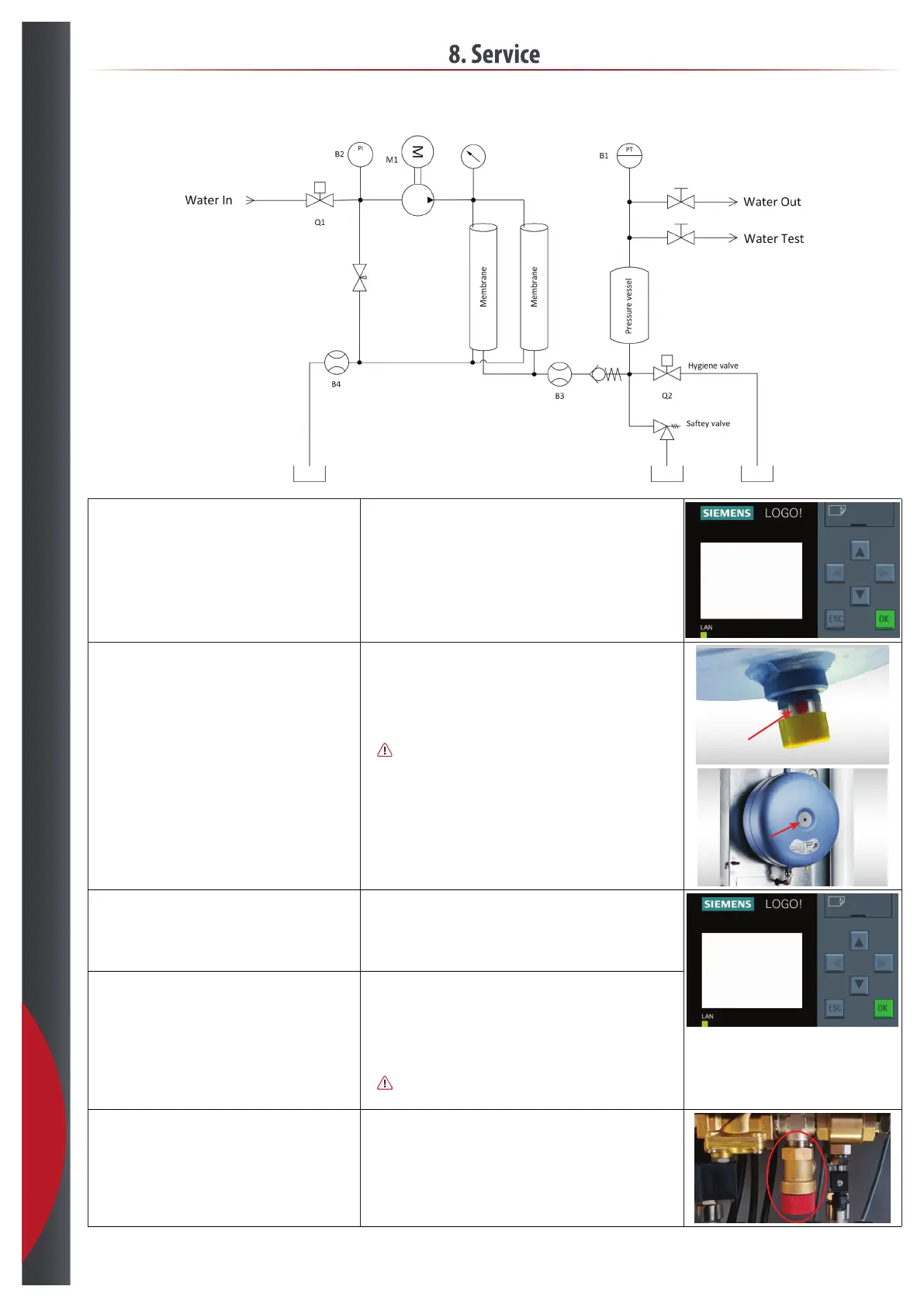

8.7 RO Inline™

Check conductivity in pressure vessel.

• Start hygiene flush, go to Cursor screen, press [ESC] + ~.

• Wait until the pump stops again.

• Open the test valve.

• Let the water run for 30 sec.

• Take a sample.

ESC+C.. 9/9

~

| }

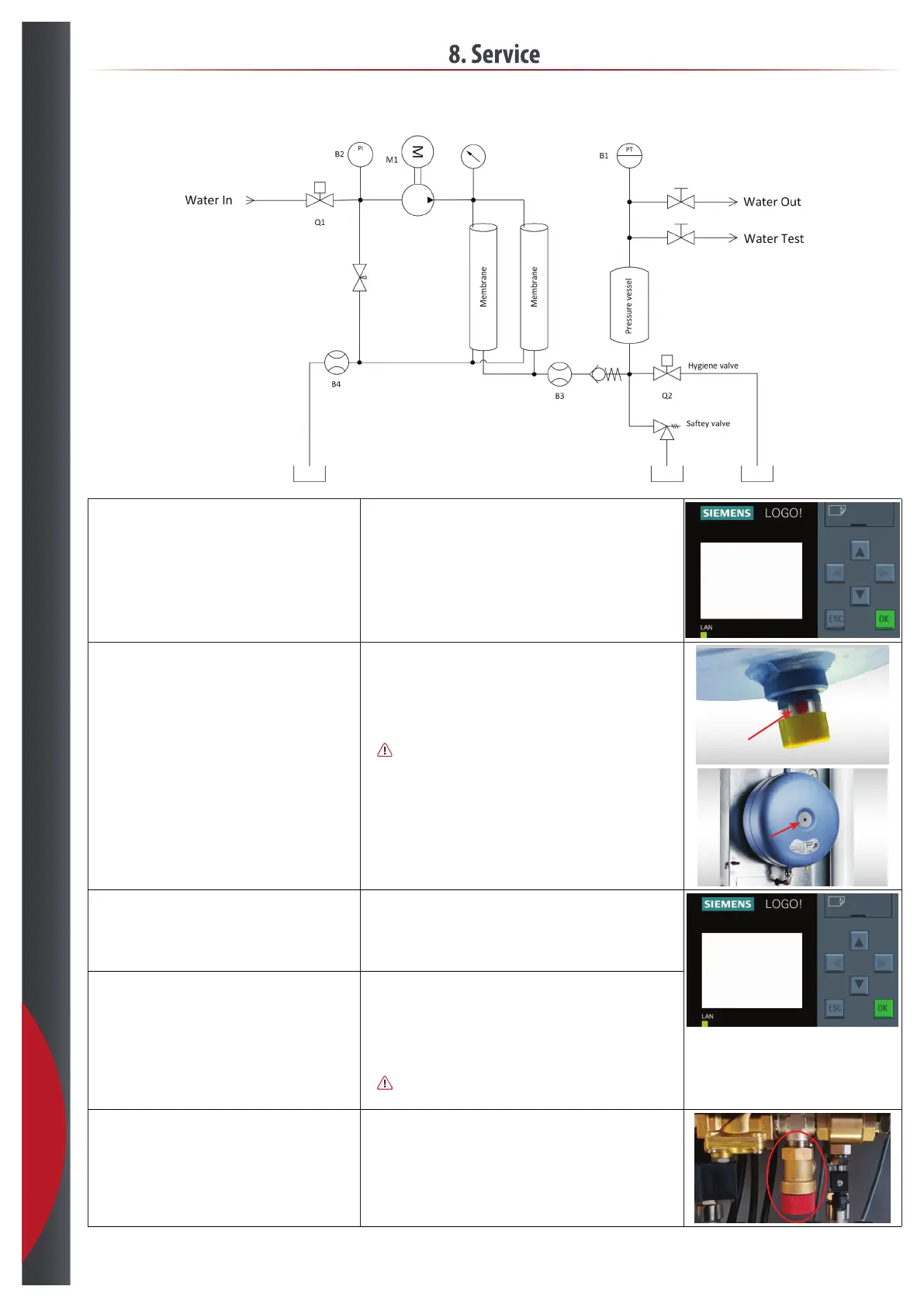

Check pre pressure in the vessel and check the membrane indicator. • Check that the membrane indicator is green.

- if the indicator is red, replace the pressure vessel.

• Stop the the humidification system.

• Close the outlet ball valve on the RO Inline™.

• Disconnect the hose from water outlet.

• Turn off fuse F1 and F2.

•

Slowly open the outlet ball valve, and empty the pressure vessel for

water, use a service hose.

• Measure the pre pressure in the pressure vessel 1,5 bar.

- adjust the if needed.

Check production. • Turn on fuse F2, wait 30 sec. and turn on fuse F1.

• Wait 60 sec. then messure production flow capacity.

• Check if the value in the display is within the same range - adjust if needed:

- Go to the flow calibration menu, password 3112.

- Follow the instructions in section 9, Screen: ”Flow Calibration”.

Vessel Pressure

B a r 4.92

Prod. l/h 300

Drain l/h 96

Drain % 32

Check drain. • Messure drain flow.

• Check if the value in the display is within the same range - adjust if needed.

- Go to the flow calibration menu, password 3112.

- Follow the instructions in section 9, Screen: ”Flow Calibration”.

• Close the outlet ball valve again.

• Reconnect the humidification system again.

•

Slowly open the outlet ball valve.

• Reset both systems if they are in alarm.

Check the safety valve. • Manually activate the safety valve, until production starts.

• Check if the valve is leaking after test.

- Replace if needed. Recommended 1 per year.

Green = OK

Red = replace pressure vessel

201218

Loading...

Loading...