63

8. Service

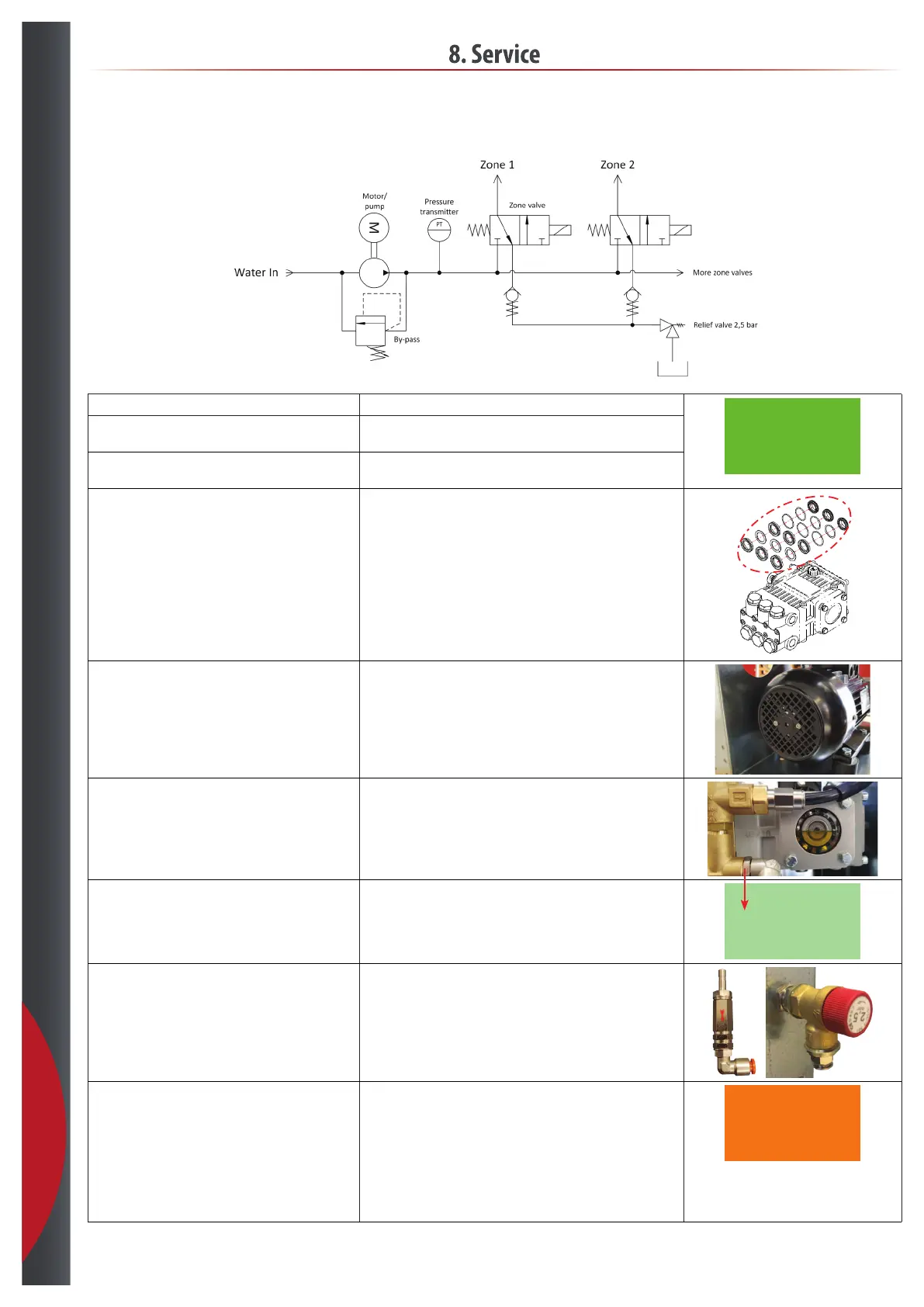

8.10 HydroSens™

Read operating hours for the pump. • In the front display, system page.

< System >

Operation, hours XXXXXX

Pump, hours XXXXXX

Oil, hours XXXXXX

Pressure, Bar XX.X

Inverter, Amps XX.X

Read total operating hours. • In the front display, system page.

Check power consumption electrical motor for high pressure pump. • In the front display, System page.

Check seals on the high pressure pump. • Water seals on the high pressure pump is replaced when leaking or every 12

months.

• If water seals are not replaced instantly when broken this could lead to oil

leak. This would not be covered by warranty.

• Use the designated tool to replace the seals to avoid damaging the new seals.

• If the pump is leaking oil, replace the pump.

Check electrical motor/ventilator for high pressure pump. • Check that the motor is running without noice.

• Check that the motor is not generating unnecessary heat, up to 80 C⁰ is ok.

• Check that the ventilator is running continuously.

• Check that the air can pass the ventilator uninterrupted – clean.

Check/change oil on the high pressure pump. • Change the oil every 2000 hours or min. one time per year

• If there is water it the oil, change the oil.

- Oil type: SAE 80W-90 GL-5

- 0,24 l for 200 to 800 l systems

- 0,42 l for 1200 l systems

Read hours on the solenoid valves. • In the front display user & maintenance menu, screen: Valve Hours.

• Recommended to replace solenoid valves after 3 years – 12.000 running hours.

• Test the solenoid valves by checking if there is running water to drain during

operations.

Zone Hours

hours hours

1 XXXXXX 6 XXXXXX

2 XXXXXX 7 XXXXXX

3 XXXXXX 8 XXXXXX

4 XXXXXX 9 XXXXXX

5 XXXXXX 10 XXXXXX

Replace non return valve on the solenoid drain and the 2,5 bar

relief valve.

• Check function by checking drain – The drain flush should only last for 1-2 sec.

- More than that and the contra valve is not closing properly.

- You can also hear it when the high pressure pump starts up. If the non

return valve is broken the pump will have to generate more speed in the

beginning and after a few seconds speed down.

- At the same time the nozzles will have bad spray, and drips when it starts

and stops.

Function test - alarms. • Low humidity alarm:

- Disconnect a sensor for a zone, the zone will stop and the system will go

into alarm, display will read ”Low %RH, Z. X”.

• High humidity alarm:

- Breathe on a sensor, system will stop and go into alarm, display will read

“High %RH, Z. X”

• No water alarm - High flow alarm:

- Close the water supply, after approximately 15 sec. the pump will stop and the

system go into alarm, display will read “High Flow/No Water”

A

L

A

R

High Flow/No Water M

High %RH, Z. 3

Low %RH, Z. 4

201218

Loading...

Loading...