61

8.9 RO Basic™

8. Service

Check conductivity in permeate tank. • Water sample is taken out at designated water test tab on the pump.

• Let the water run for 1 min.

• Flush the test tube.

• Follow the instructions for the supplied conductivity reader.

Check production on each membrane individually. • Stop the RO system by the power supply.

• Take off hose between membrane and permeate tank at the tank.

• Install flow reader.

•

Prepare drain as described below before starting the system.

• Start up RO system.

• Note the flow.

Check drain flow during production. • Take the drain hose and install the flow reader.

• Start RO system.

• Note the flow.

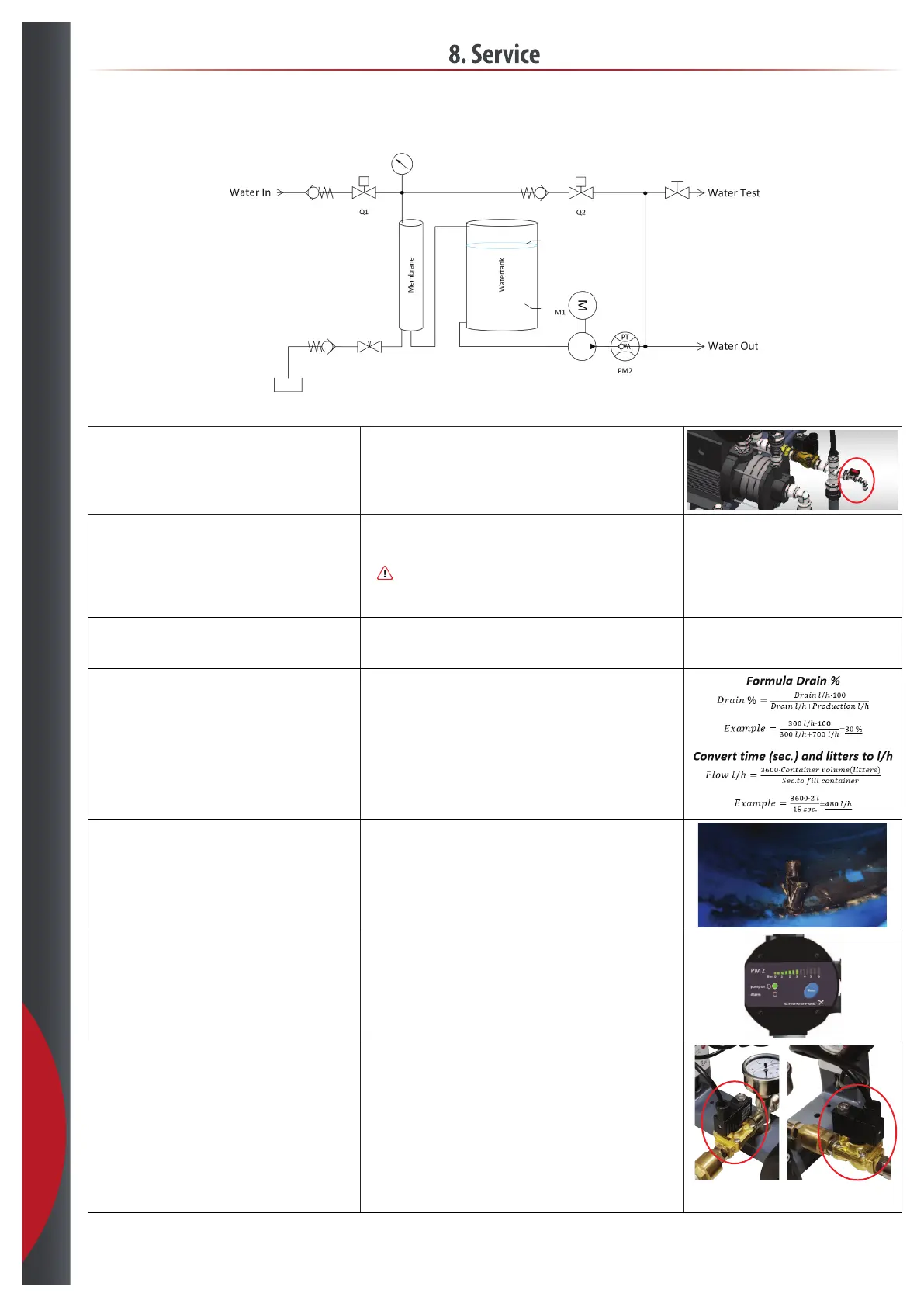

Calculate the drain %. • Use the formula to calculate the drain %.

- With softener drain % > 30 %

- Without softener drain % > 50 %

• If the drain % is below the required level, then adjust the drain flow and test

again, see section 6.6 Adjust drain %.

Check that the permeate tank is clean. • Take the lid of the tank and check visually if the tank is clean.

• If the tank is not clean, clean the tank with warm water or suitable desinfectant.

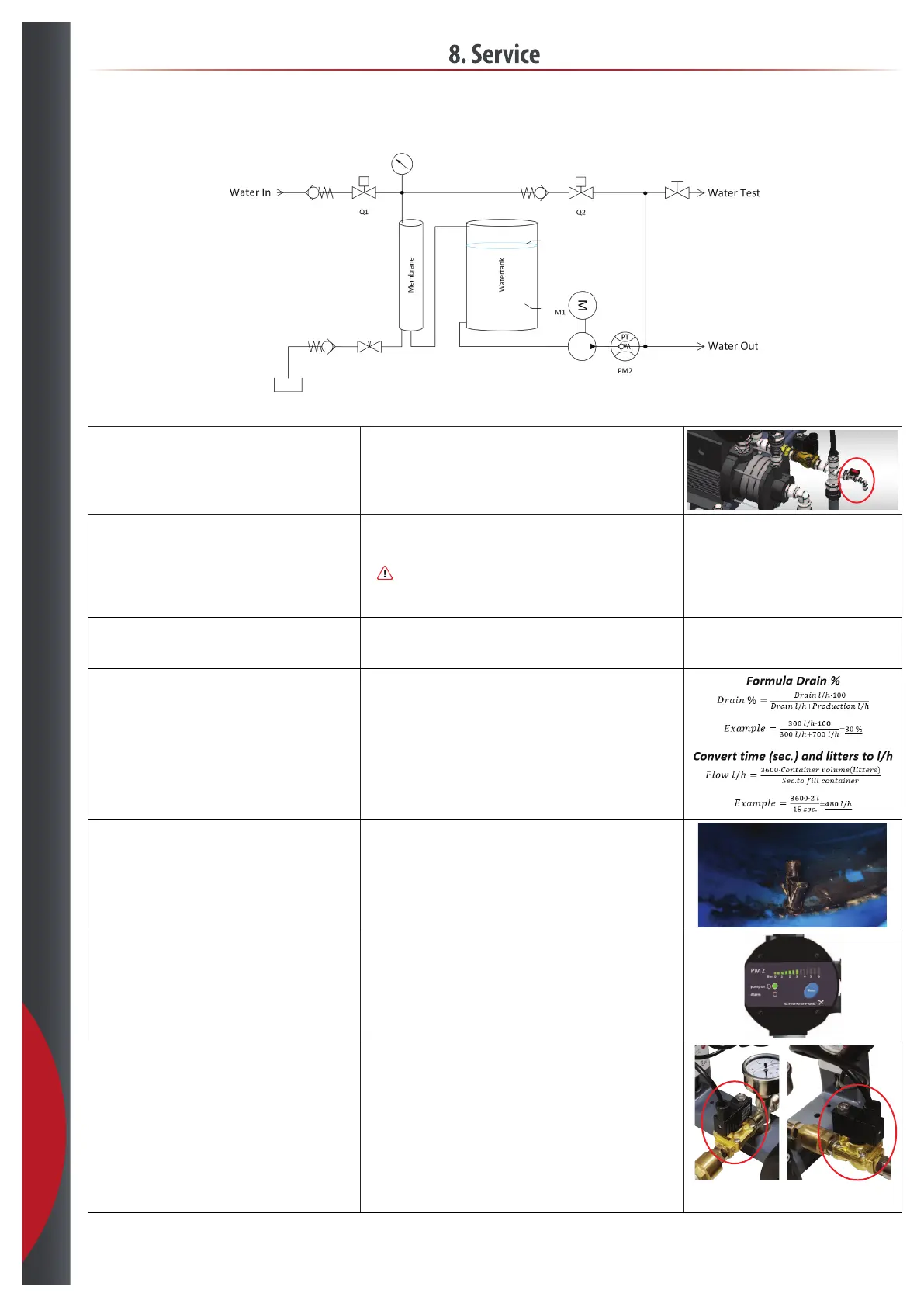

Check functionality of the booster pump from the tank. • Starts at 1,5 bar.

• Stops at 3.5 - 4 bar if there is not water requirement.

Check solenoid valves. • Solenoid valve on water inlet is checked by:

- Shutting down the RO system.

- The pressure on water should drop to 0 bar.

• Read on the pressure gauge.

• Solenoid valve on rinse water is checked by starting the RO with an empty tank:

- Empty tank to lowest sensor – production starts. When it stops see that

solenoid valve opens and starts rinse cycles.

- The system will start by rinsing.

- The flow should be higher then normal operation flow to drain.

- After 45 seconds the flow should drop to the set flow.

- If the flow does not drop the solenoid valve is defect.

Inlet Rinse

201218

Loading...

Loading...