71

9. Display Menu

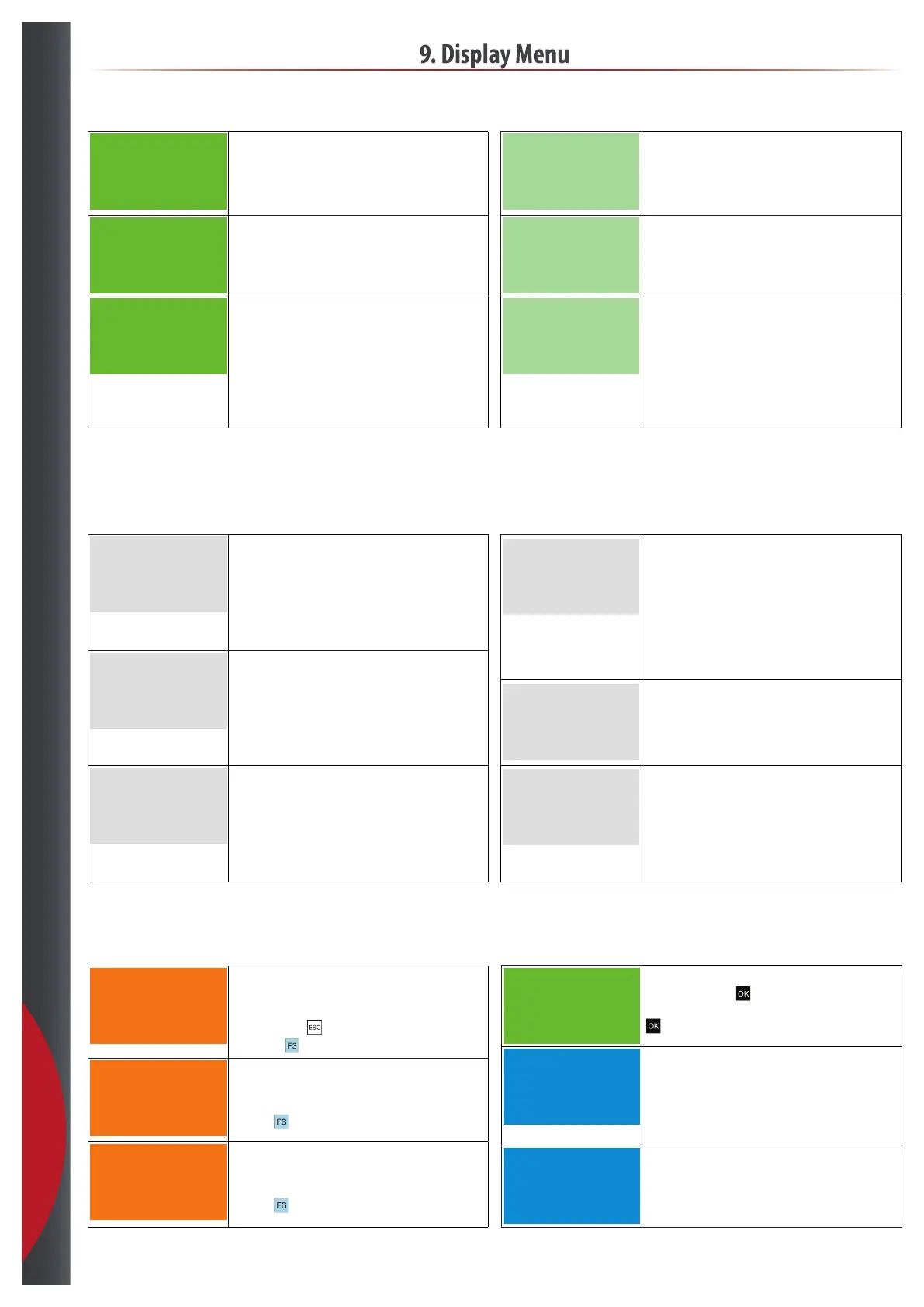

Information and daily setup screens

Airtec HydroSens

< AHU >

Software V. 1.00

Status OK

- Software type/version and system status.

< AHU Overview >

°-1- °-2- °-3-

Step X X X

Control % XXX XXX XXX

Room %RH XXX XXX XXX

Setpoint XX XX XX

Duct %RH XXX XXX XXX

Setpoint XX XX XX

- Step, control %, room and duct %RH/setpoint.

To change setpoints, enter password.

< System >

Operation, hours XXXXXX

Pump, hours XXXXXX

Oil, hours XXXXXX

Reset Service Yes

Pressure, Bar XX.X

Inverter, Amps XX.X

Show Service popup Yes

- Hours, pressure and amps.

User password can:

- reset service (incl. oil hours).

Maintenance password can also:

- edit pump and oil hours.

- enable/disable service popup .

Shared User and Maintenance setup Screens

Valve Hours

D1.1 XXXXXX D3.1 XXXXXX

D1.2 XXXXXX D3.2 XXXXXX

D1.3 XXXXXX D3.3 XXXXXX

D2.1 XXXXXX

D2.2 XXXXXX

D2.3 XXXXXX

- Valve hours.

User password:

- read only.

Maintenance password:

- edit valve hours.

Flow Limit

D1.1 XX.X D3.1 XX.X

D1.2 XX.X D3.2 XX.X

D1.3 XX.X D3.3 XX.X

D2.1 XX.X

D2.2 XX.X

D2.3 XX.X LowFlow XX.X

- Flow limit for all valves and LowFlow.

Read only, value is automaticly stored during ow test.

Flow Test & Setup

Test Duct X.X Yes

Hysteresis, Hz XX.X

Inverter Freq, Hz XX.X

LowFlow Installed Yes

Alarm Delay, Sec. XX

Alarm On

- Flow test, hysteresis, inverter Hz, ow alarm & delay

User password can:

- run ow test (select duct/valve and change No to Yes).

- edit hysteresis.

Maintenance password can also:

- enable/disable LowFlow installed.

- set ow alarm delay.

- turn ow alarm o. After 1 hour it turns on again

Maintenance setup screens

AHU Control Setup

AHU 1 0-100%

AHU 2 Room %RH

AHU 3 O

Oset %RH ± Room/Duct

AHU 1 -X/-X

AHU 2 -X/-X

AHU 3 -X/-X

- Setup of control method and sensor oset

Control methods:

- O Deactiveated.

- 0-100% External controlsignal 0-10 V DC.

- Room %RH Room humidication sensor 0-10 V DC.

Sensor Oset ± 9 %RH.

PI Gain and time

Room

P gain xxx

I time xxx

Duct

P gain xxx

I time xxx

- Reaction setup

P gain How much it reacts (1-255).

the higher the number the more it reacts.

I time How fast it reacts (1-255).

the lower the number the faster it reacts.

Alarm %RH & Hysteresis

Low limit, %RH XX

High limit, %RH XXX

Duct 1, %RH XX

Duct 2, %RH XX

Duct 3, %RH XX

Hysteresis Downstep X

- %RH alarm limits and downstep hysteresis.

%RH alarm limits:

- Low limit Room low limit (default 10).

- High limit Room high limit (default 80).

-Duct X Duct max. limit (default 88).

Hysteresis Delayed stepdown in % control signal.

Alarm Out NC

External Alarm NC

Alarm Delay, Sec. XX

Enable 2nd PLC Yes

Valve Pause, Sec. XX

Hygiene Rinse

Rinse time, Sec. XX

Hours between XX

- Setup alarm out, 2

nd

PLC, valve pause and rinse

- Alarm Out Normaly Closed/Open.

- External Alarm IN Normaly Closed/Open.

- Ext. Alarm Delay Sec. before alarm.

- 2nd PLC Installed Y/N (AHU 3).

- Valve pause Sec. between stop and start.

Hygiene Rinse:

- Rinse time Length of hygiene rinse (sec.).

- Hours between Hours between hygiene rinse

SDcard

Backup SDcard Yes

- Setup SDcard fault message (from V.2.40)

Backup SDcard

- Yes Enables the SDcard fault screen.

- No Disables the SDcard fault screen, but

backup is still done if a SDcard is present.

Adjust By-Pass

Adjust By-Pass Yes

Pressure, Bar XX.X

- Pressure and adjusting by-pass.

Before adjusting, make sure one valve is open!

Adjust by-pass:

- change ”No” to ”Yes” (resets to ”No” after 30 sec.).

- adjust by-pass.

- return to ”No”.

- lock by-pass position.

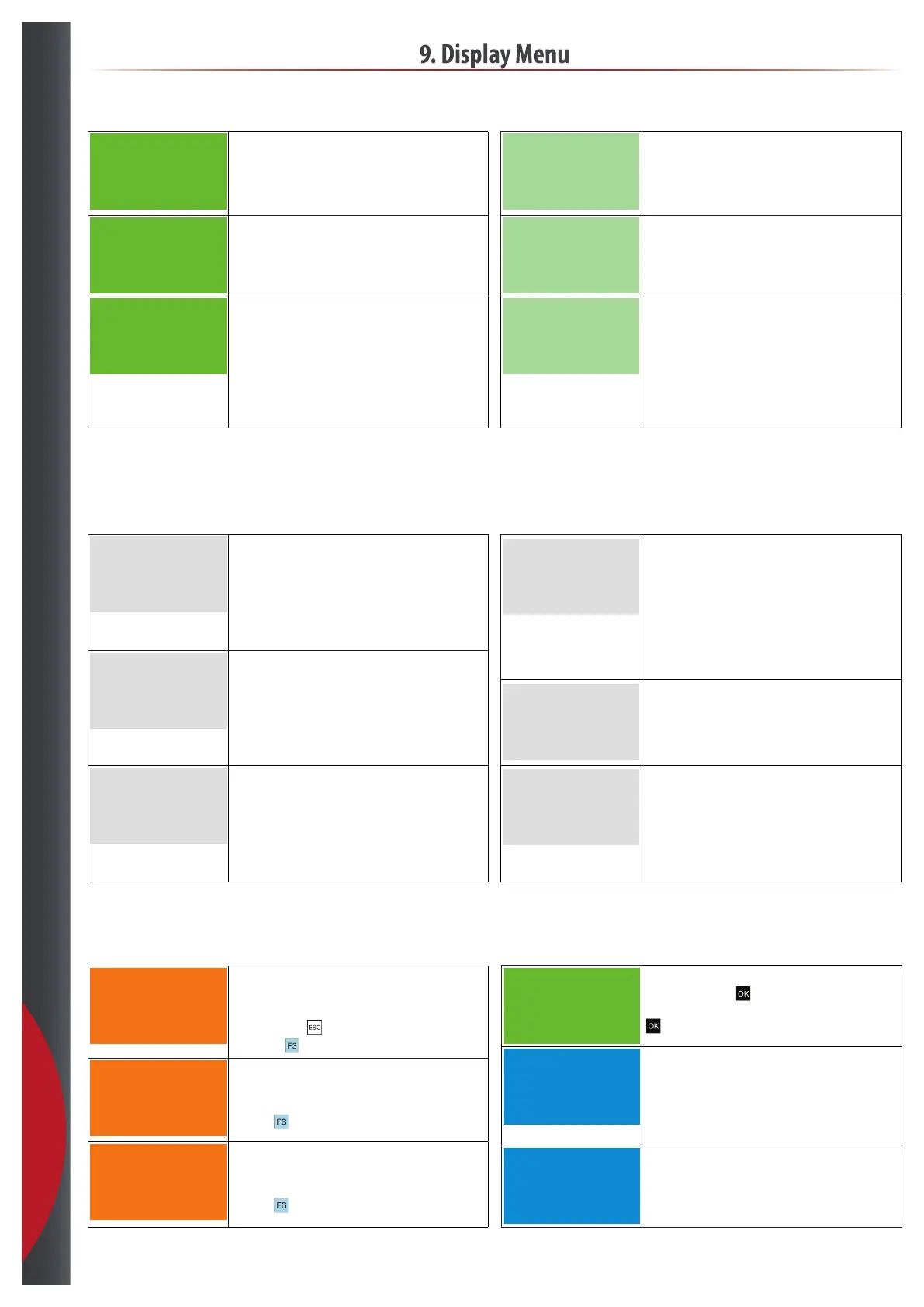

Alarm screens

Temprature pump° A

Modbus Fault° L

Inverter Fault° A

Pressure Alarm R

High Flow/No Water M

High %RH in Room 1 2 3

Low %RH in Room 1 2 3

High %RH in Duct 1 2 3

- Alarm screen.

Here you can see the active alarms - see troubleshooting.

-if the ° is shown at the rst three, the fault is still activ.

Goto alarm screen,

> 2 sec.

Reset alarms

Alarm Log

Power XXXXX

Temperature Pump XXXXX

Modbus Fault XXXXX

Inverter Fault XXXXX

High Pressure XXXXX

Max. Pressure, Bar XXX.X

Reset Press -F6-

- Alarm log screen 1.

Info about how many times an alarm has appeared.

Maintenance password:

- reset log

Alarm Log

High Flow XXXXX

High Flow/No Water XXXXX

High %RH in Room XXXXX

Low %RH in Room XXXXX

High %RH in Duct XXXXX

Reset Press -F6-

- Alarm log screen 2.

Info about how many times an alarm has appeared

Maintenance password:

- reset log

Password, service and SDcard fault screen

Password

0000

Press OK

- Setup alarm out, 2

nd

PLC, valve pause and rinse.

Goto password screen,

> 2 sec.

Enter password.

Service

- Time for service.

Appears the rst time, when the pump has run for 300 h.

It reappears for every time the pump has run for 2000 hours or

half a year, depending on what comes rst.

When leaving the screen it reappears after two days, until

”Reset Service”.

SDcard Not Present/

Fault SDcard

Fault Code: x

- SDcard not present or fault SDcard (from V.2.40).

Missing SDcard or fault in read/write on SDcard:

Fault Code 1: SDcard not present.

Fault Code 2: Datale on SDcard is full.

Fault Code 3: SDcard is broken/full/read only.

201218

Loading...

Loading...