85

11. Troubleshooting

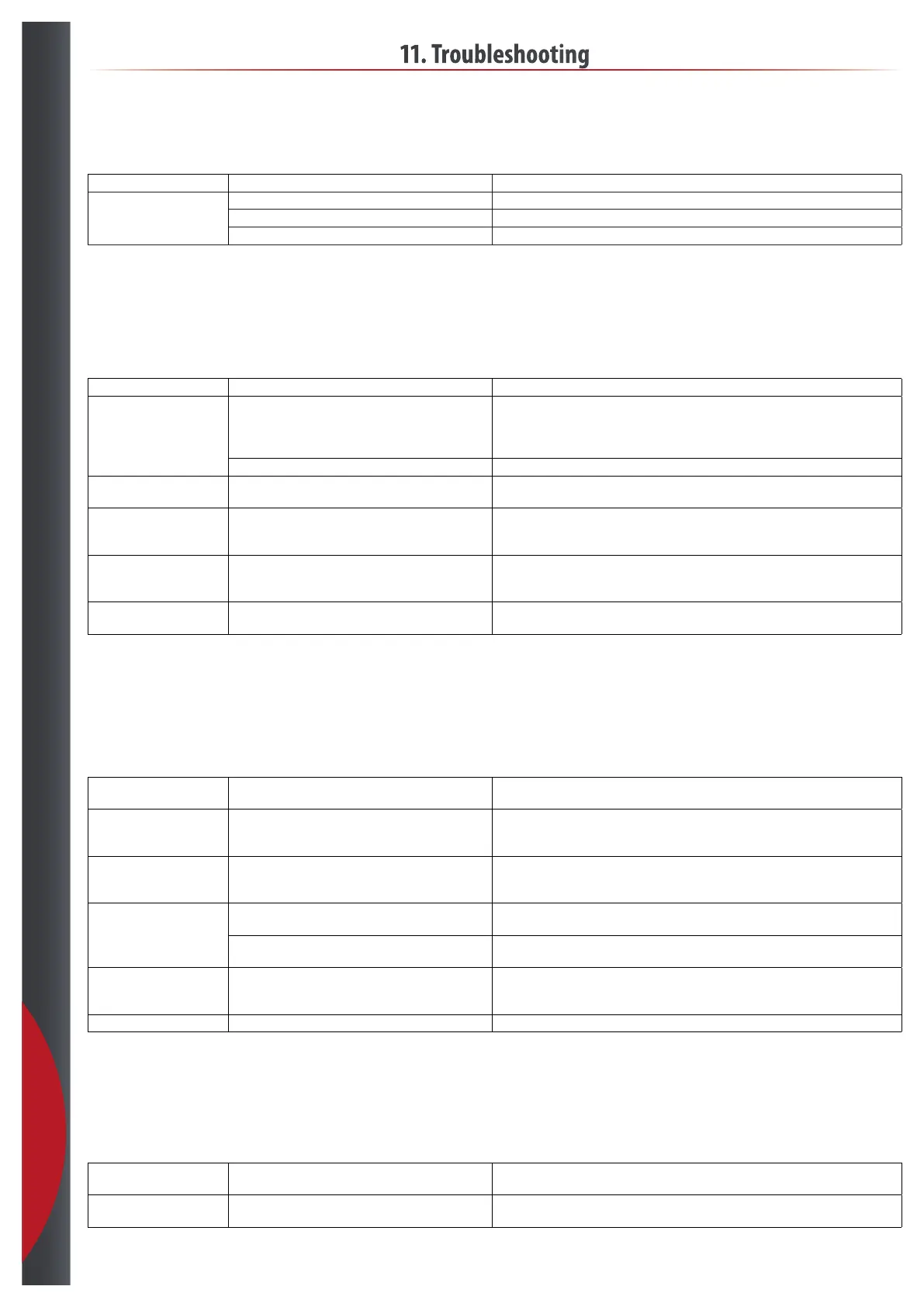

Softening - High Salt Consumption

Problem Cause Solution

1. Regenerates too frequently. See the section entitled ”Softening - frequent regeneration”. See the section entitled ”Softening - frequent regeneration”.

2. Water level in the brine drum

is too high.

The brine valve is set wrong or non-conforming. Verify the brine valve setting. Replace non-conforming brine valve.

The brine valve or the brine drum is dirty. Clean brine valve and drum.

The brine valve leaks. Tighten the connectors on the brine valve.

Softening - salty treated water

Problem Cause Solution

1. Restricted drain line. The drain is kinked or clogged. Clear any obstructions. Make sure that the drain line ows smoothly and unrestricted.

2. Low water pressure. The unit should not see water pressure drop below 1 bar / 15 psi

on the outlet at any time. During the backwash portion of the

regeneration cycle, it must hold at least 1 bar / 15 psi or the brine

may not rinse out completely.

Test the outlet pressure with the unit in backwash and one faucet at high ow. Measure the pressure by

placing a gauge on the brine tting. Raise pressure if below 1 bar / 15 psi.

The prelter cartridge is clogged. Replace prelter cartridge.

3. The backwash ow control is

clogged.

Without enough backwash ow to the drain, the unit cannot

wash all the salt from the media tanks.

Clean the backwash ow control.

4. The drain is extremely long or

placed higher than 2,4 m / 8 ft

above the oor.

Such drain runs can put back-pressure on the unit and restrict the

drain ow. This causes the same result as number 3 above.

Locate a closer drain or use a larger diameter drain line.

5. The upper distributors are

plugged. (This does not apply

to High Eciency softeners.

Foreign material that nds its way into the media tanks may

be collected around the upper distributors during backwash,

clogging them.

Clean upper distributors. Install a prelter.

6. Water level in the brine drum

is too high.

The brine valve is set wrong or non-conforming. Verify the brine valve setting. Replace non-conforming brine valve.

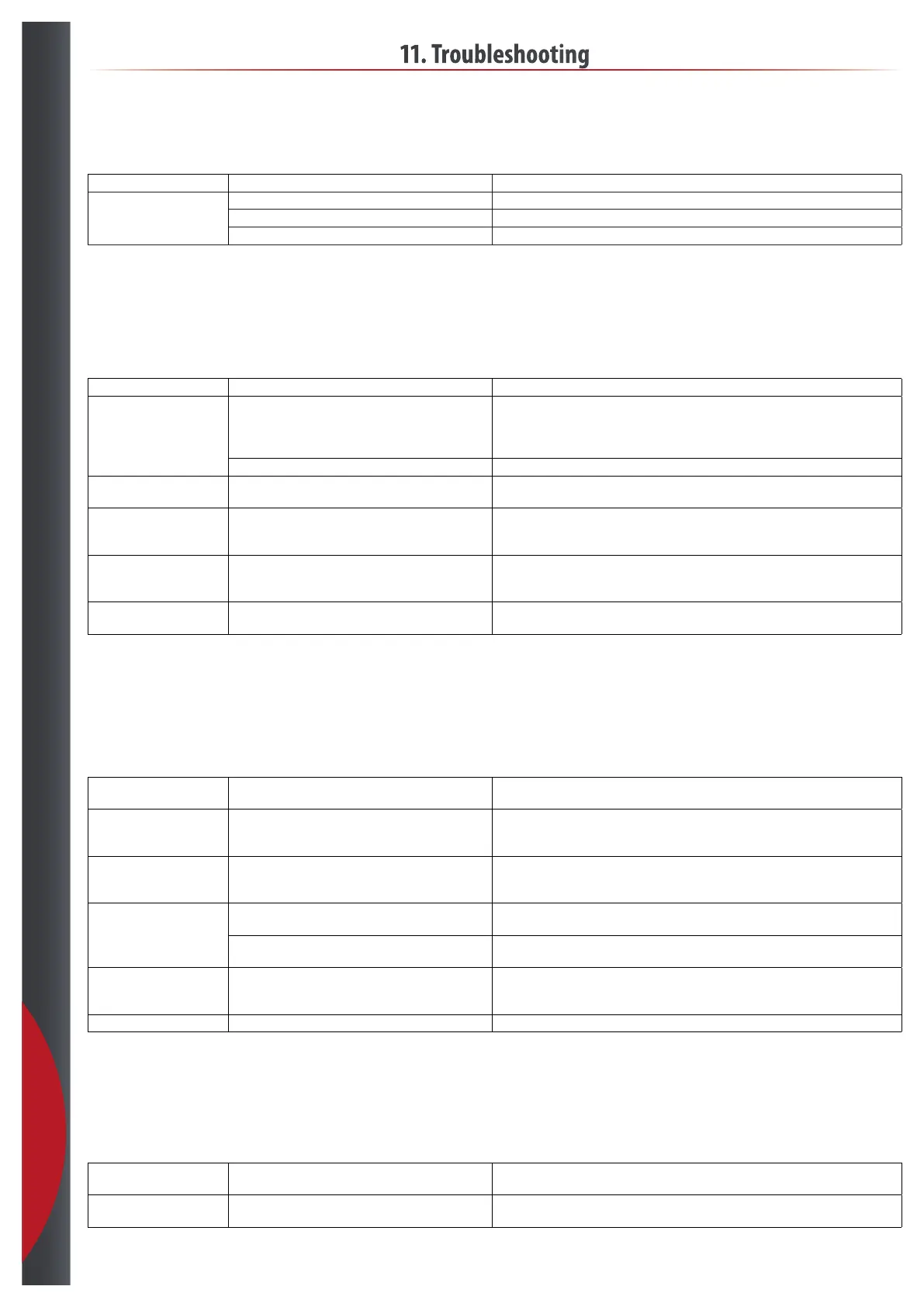

Softening - iron bleed-through

Problem Cause Solution

1. Customer plumbing. Previous iron buildup inside existing plumbing after the water

softener.

Verify that customer plumbing is the problem by testing the water quality at the brine tting with

water running.

2. The water meter disc is not set

properly for current raw water

conditions.

The composition of raw water can change with time. Check the hardness and iron content of raw water. Install the correct disc for current raw water

conditions.

3. The salt setting is not set

properly for current raw water

conditions.

The composition of raw water can change with time. Check the hardness and iron content of raw water. Set the brine valve for current raw water conditions.

4. The iron may be ferric iron. Ferric iron is not removable by ion exchange. Verify by using the demo softener to determine if iron is removable by ion exchange. Add additional

equipment if needed.

The iron may be ner than the micron rating of the installed

prelter cartridge.

Install a cartridge with ner micron rating.

5. The customer’s plumbing may

include a galvanized pressure

tank.

A galvanized pressure tank will create oxidized iron. Replace the galvanized pressure tank with a bladder style pressure tank.

6. Iron build-up in the softener. High iron bearing water. Use salt that contains resin cleaning additives.

Softening - pressure loss

Problem Cause Solution

1. Reduced pressure entering

the unit.

The prelter is clogged. Replace the clogged prelter.

2. The upper and/or lower

distributors are clogged.

Foreign matter from the input lines is accumulating in the

distributors.

Clean the distributors. Add a prelter to eliminate the foreign matter before it enters the unit.

201218

Loading...

Loading...