120

REPLACEMENT OF MAIN COMPONENTS

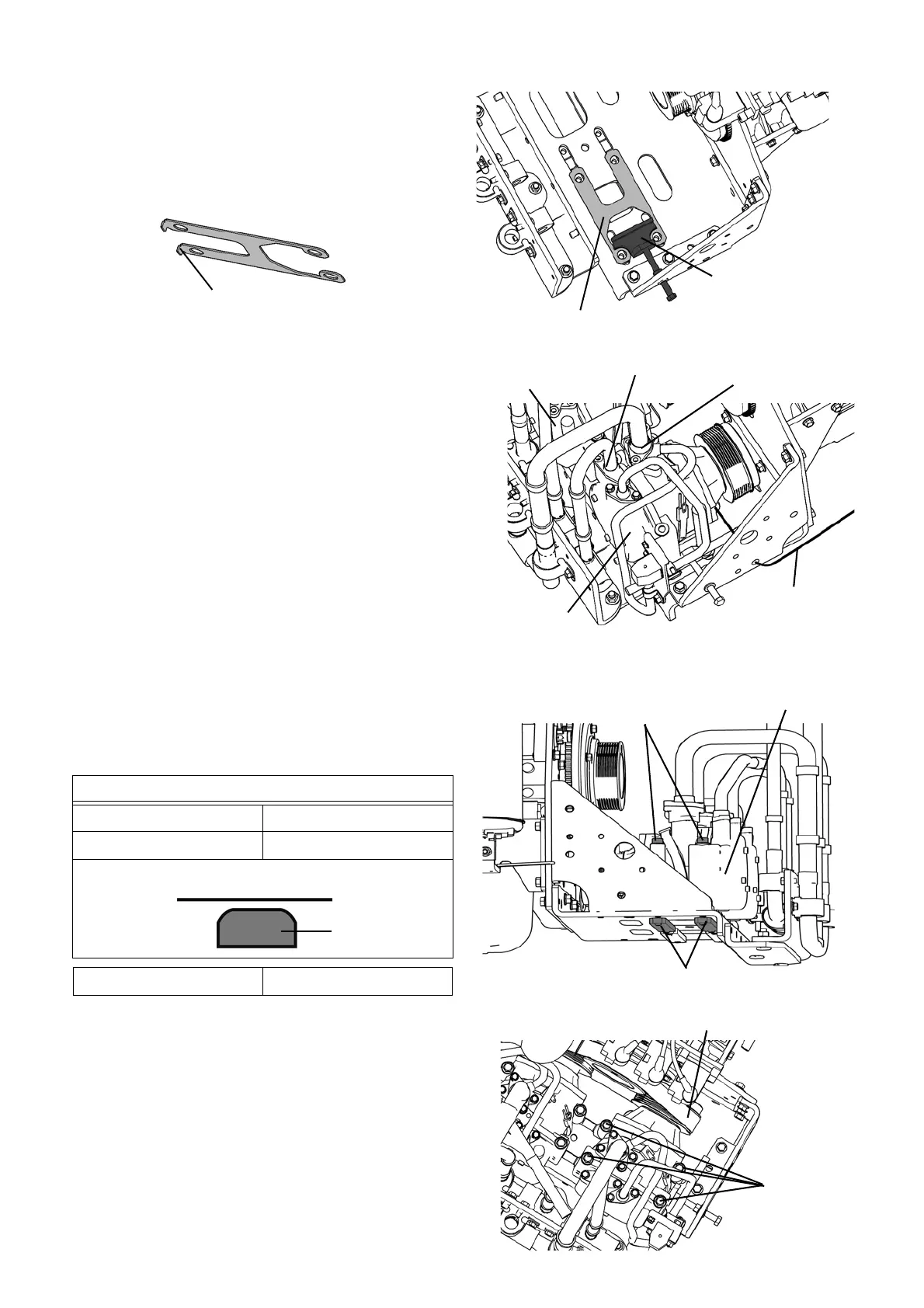

5. Check that the steel plate and the bracket under the

compressor main unit are in the correct position

(see right).

NOTE) Mount the steel plate so that the bent portion

faces down.

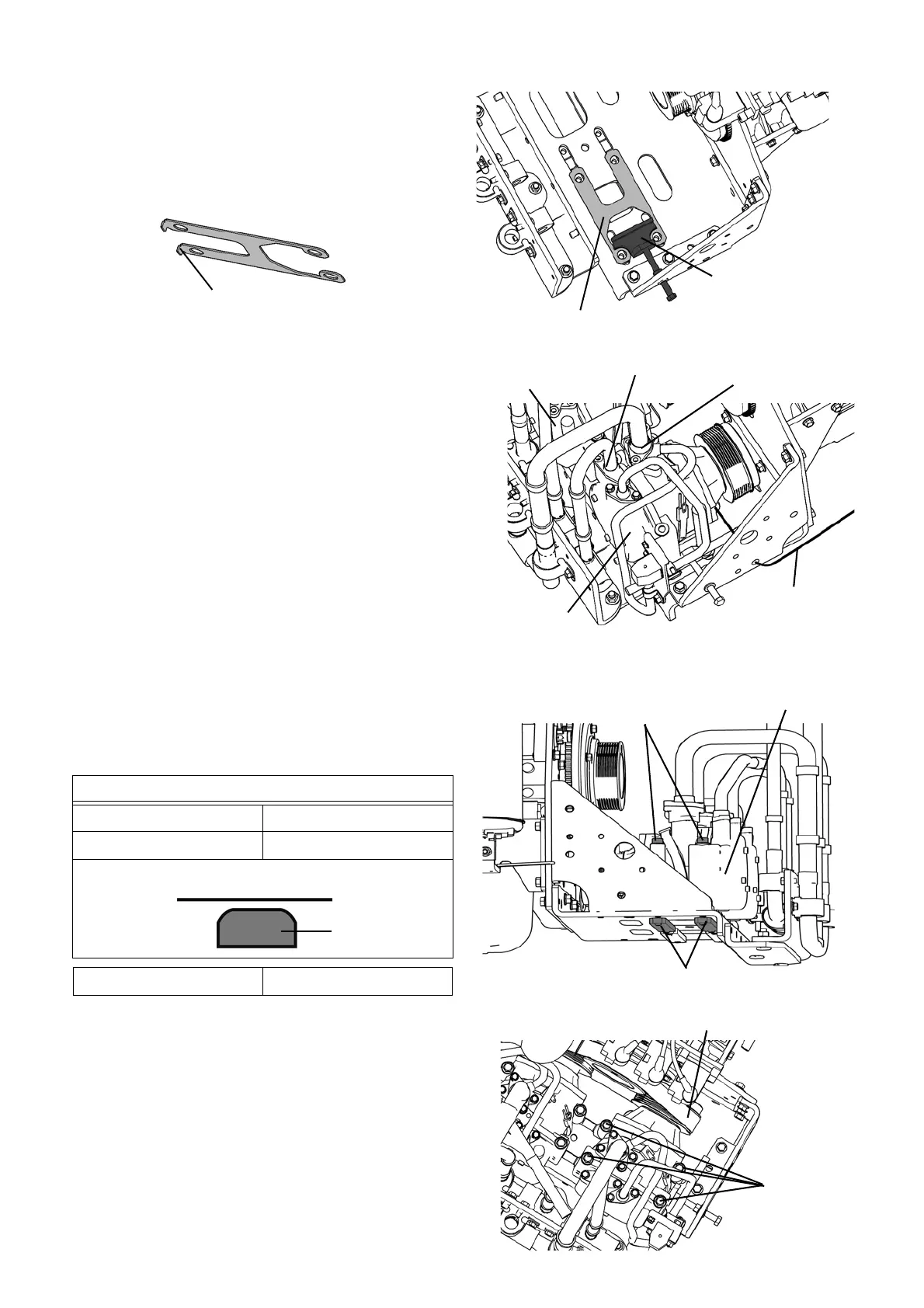

6. Mount the compressor on the compressor bracket.

1) To prevent pinching or hooking, move the wire har-

nesses of the compressor discharge pipe tempera-

ture sensor and refrigerant high pressure switch

above the discharge pipe (No. 1 compressor) or

between the discharge pipe and intake pipe (No. 2

compressor).

2) Connect the oil tube to the compressor. Mount the

No. 2 compressor and No. 1 compressor on the

compressor bracket in order.

NOTE) Insert the oil tube until it hits a dead end.

NOTE) Take care so that the flanges (o-ring contact

surfaces) of each port are not damaged.

3) Hold the 2 stays (plate-shaped) at No. 2 compres-

sor side under the bracket with your hand paying

attention to the direction.Holding the stays, tighten

4 bolts firmly of No. 2 compressor.

4) Attach the compressor belt to the compressor.

Bracket

Iron plate

Bent portion

Intake port

Discharge port

Oil tube

No.2

No.1

Bolts (4 pieces)

Stays

No.2

Stay mounting position

Rounded corner Bracket side

Sharp corner Base plate side

Tightening torque 31.0 lb·ft (42 N·m)

Stay

Bracket side

Compressor belt

Bolts

Loading...

Loading...