201

TROUBLESHOOTING

10) Inspect Spark Plug

5) Select "Actuators output condition/individual actuating (code No. 20)" in the check mode of the board mainte-

nance functions. Turn ON "Main side output permission", "Engine side output permission", "Starter transform-

er", "Ignition circuit drive signal", and "Starter" in order so that the starter can operate for 5 seconds to crank

the engine. Check if there is a spark at the electrode of the spark plug.

3) Mount the spark plugs as before.

NOTE) When mounting the spark plug, make sure to tighten it first by hand. After that use a plug wrench to

tighten it up to the specified torque.

11) Inspect High Voltage Cable

Connection failure of the high voltage cable to the connector or an internal disconnection of the cable may cause

malfunctions due to noise influence including a sudden engine stall, oil pressure or engine coolant temperature

abnormality from unknown causes.

1. Turn OFF the electric leakage breaker.

2. Inspect for connection failure of the high voltage cable connector to the spark plug or ignition coil.

3. Measure resistance at both sides of the high voltage cable and check for any abnormality such as disconnec-

tion.

1. Spark check of spark plug

1) Close the fuel gas valve.

2) Pull the caps to remove the cables.

NOTE) Do not pull the cable.

3) Remove the spark plugs with a plug wrench.

Cap

4) Attach the spark plug to the high voltage a cable, and make the spark

plug body (screw part) contact to the engine.

Be sure to get your hand off of the spark plug, before engine cranking.

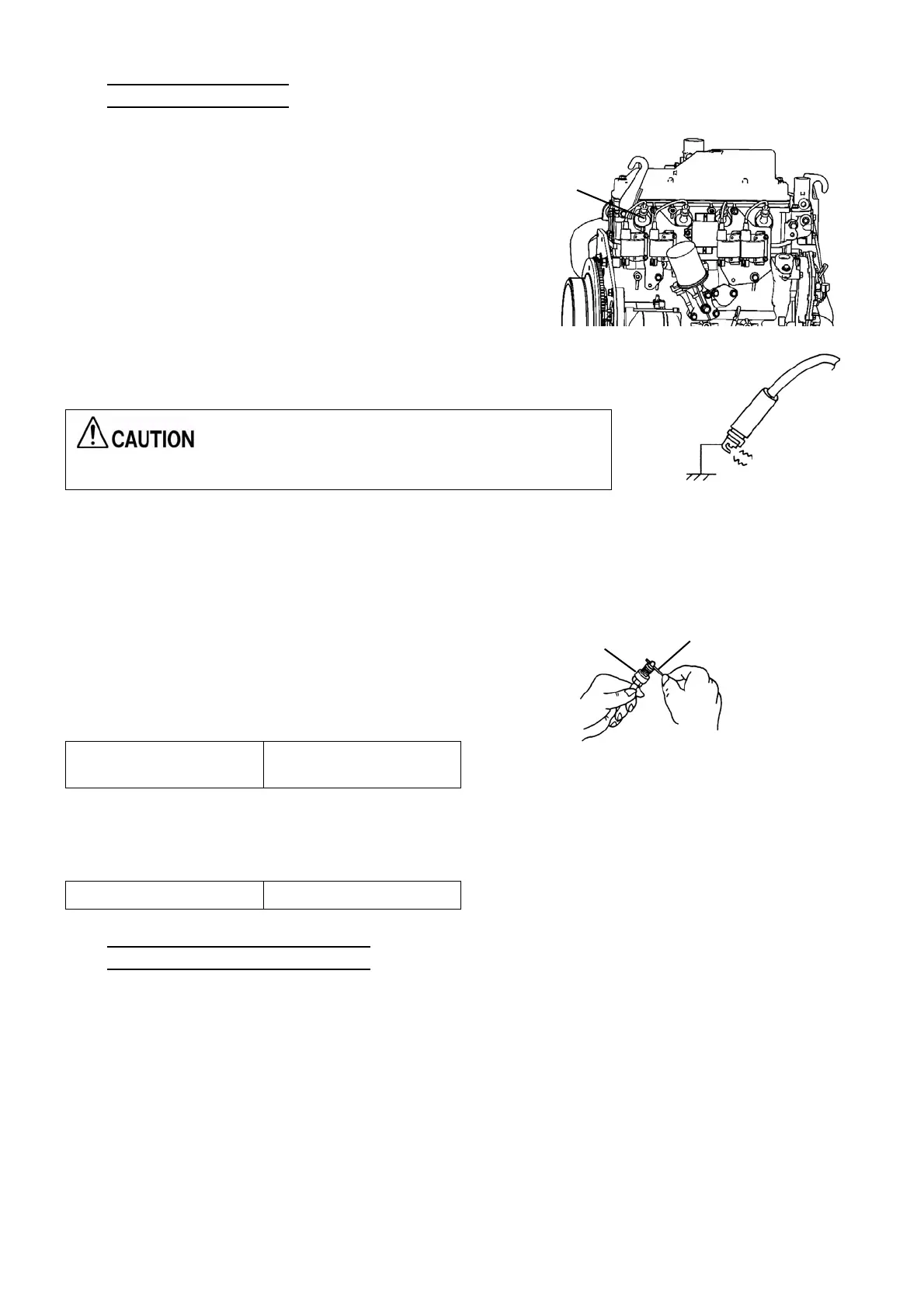

2. Inspect spark plug electrodes

1) Check for burnout, dirt or abnormal wear on the

electrode portion of the spark plug.

2) Check the clearance of the electrodes with a feel-

er gauge.

Electrode clearance

standard value

0.016 ~ 0.039 inch

(0.4 ~ 1.0 mm)

Tightening torque 15 ~ 22lb·ft (20 ~ 30 N·m)

Plug

Feeler gauge

Loading...

Loading...