54

PERIODIC INSPECTION

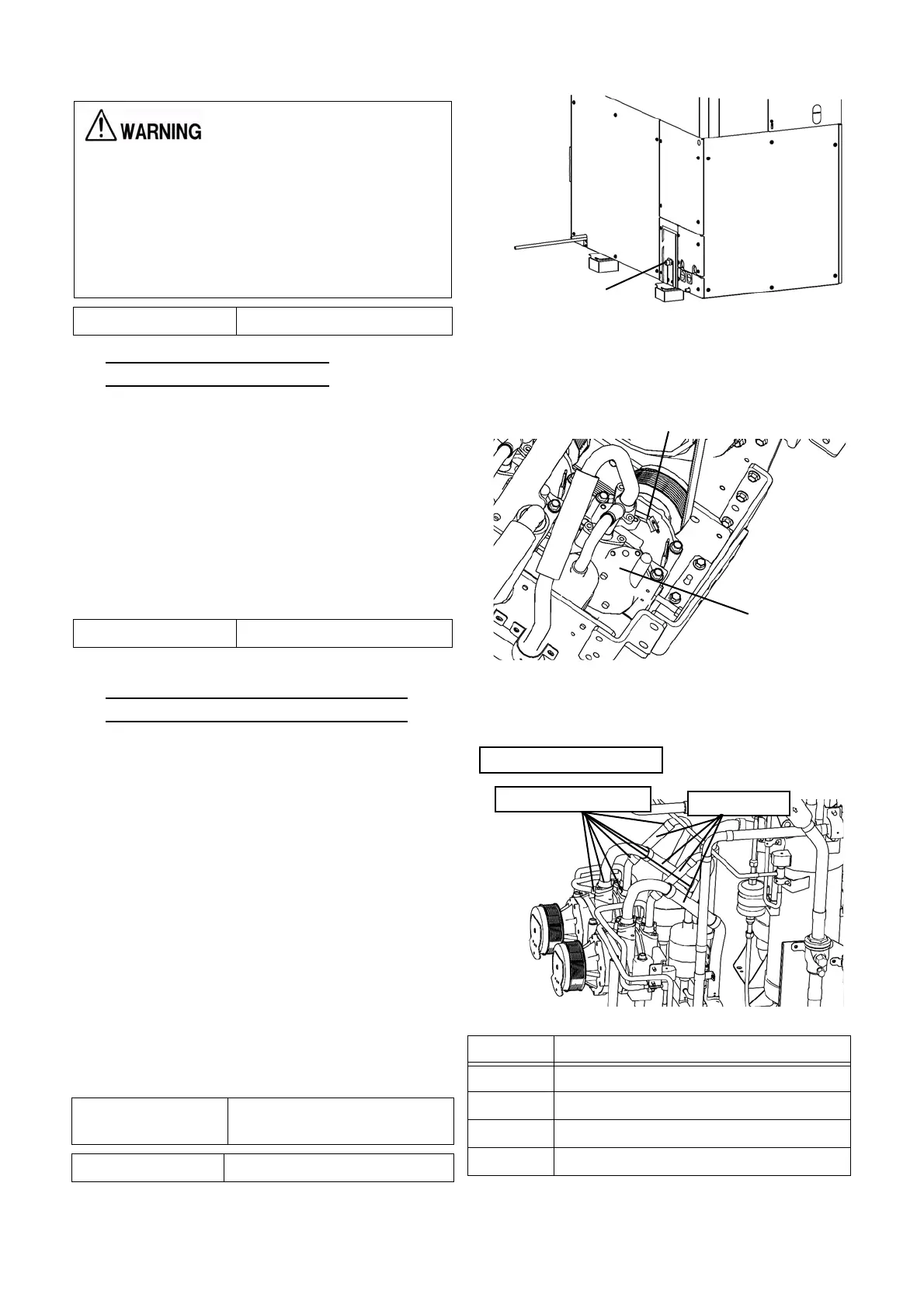

16) Compressor Inspection

1. When the GHP is stopped, turn the compressor shaft

by hand and check that it turns smoothly.

2. Check the compressor unit for refrigerant or refriger-

ant oil leakage.

3. Touch the compressor heater with your hand to

check if it is warm.

NOTE) Depending on the ambient temperature,

compressor heater may not be electrified.

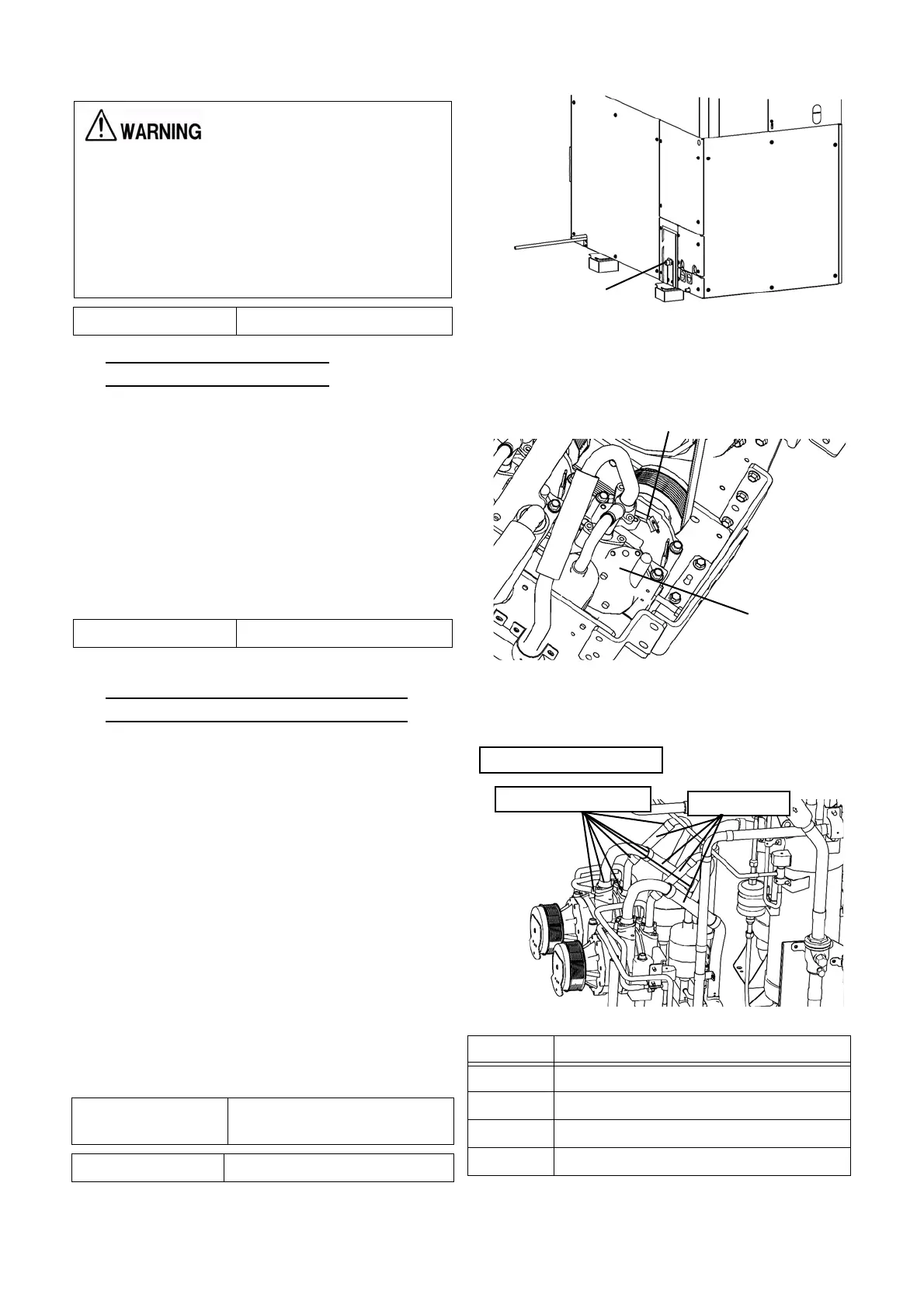

17) Refrigerant Leakage Inspection

1. Check the refrigerant line and refrigerant line con-

necting points for refrigerant leakage.

2. Check and record the values in the right table with

the monitor mode in the board maintenance func-

tions during operation.

Opening for fuel gas pipe

If there is any problem such as fuel gas leakage or

fuel gas odor during inspection, be sure to fix the

problem.

If there is dirt or leaf soil around the fuel system

parts, be sure to clean up around the fuel system

parts.

Inspection interval Every 3 years (10,000 hours)

Compressor

Compressor heater

Inspection interval Every 3 years (10,000 hours)

Portions prone to leakage

Flexible tubes

Line connecting points

Code No. Items to be checked

41 Refrigerant low pressure

40 Refrigerant high pressure 1

11 Actual engine speed

- Number of connected compressor units

Operating condition

Operate all indoor units with

maximum load

Inspection interval Every 3 years (10,000 hours)

Loading...

Loading...