39

PERIODIC INSPECTION

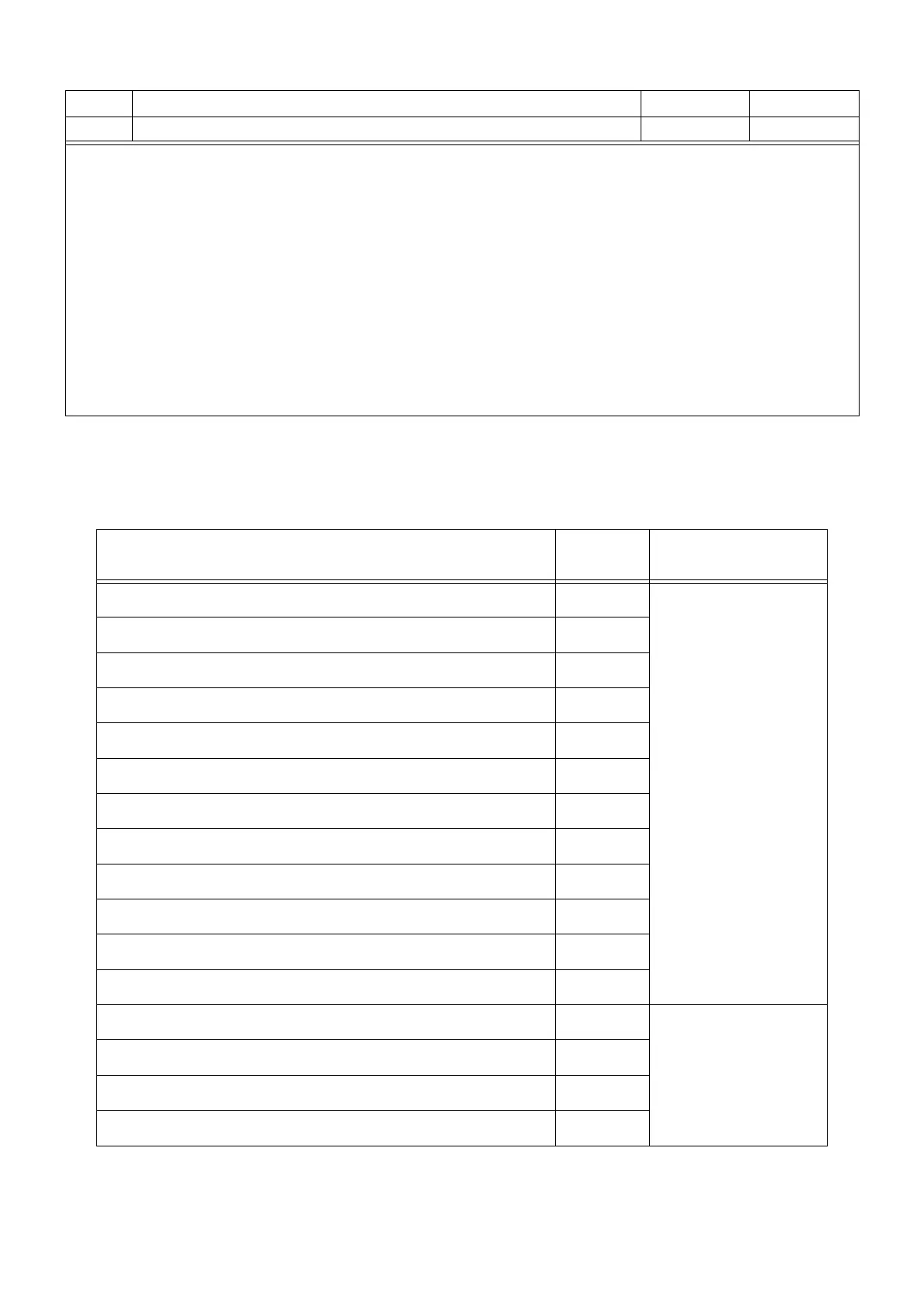

2. Parts Requiring Periodic Replacement

※ "Quantity" column shows the maximum number of the parts to be used for E model.

※ See parts catalog for parts NO.

34 Remote Controller Operation Inspection △△

35 Indoor Unit Temperature Inspection △※ △※

1. Perform periodic inspection in accordance with the table above, every 3 years or every 10,000 hours, whichever

comes first. (Use the genuine parts specified by AISIN for replacement, refill, engine oil, engine coolant, engine cool-

ant additive, and valve cleaner.)

2. Symbols:

● : Replacement, ▲ : Cleaning, △ : Inspection (adjustment, refilling). ※Symbol: inspection to be carried

out while the GHP is operating.

3. For the items requiring only "inspection (

△ )", it is necessary to replace the part if a problem is found in inspection.

4. When refilling engine coolant additive, supply the specified amount to the reserve tank. Refill the engine coolant of

specified concentration for the shortfall. The specified concentration is 50~60 vol% (engine coolant: 0.55, water:

0.45). If an optical densitometer is used to measure the concentration, reading of 40~48 % of the densitometer cor-

responds to the specified concentration.

5. Refill the engine oil only the consumed amount.

6. Refill the exhaust water drain filter only the consumed amount.

7. Tell your customers to consult the dealer regarding inspection in the 7th year and after.

Part name Quantity

Replacement /

Use intervals

AISIN Gas Engine Oil L-10000G (2.6 gal (10 L) can) 2

Every 3 years or

10,000 hours

Oil filter 1

Spark plugs 4

Air filter elements 2

Compressor belts 1

Exhaust water drain filter (2.2 lbs (1 kg) container) 1

Exhaust water drain filter gasket 1

Drain oil filter No. 1 1

Drain oil filter No. 2 1

Engine coolant additive (16.9 fl oz. (500 mL) container) 1

Engine coolant 1

Valve cleaner 1

Fuel gas hose (gas mixer side) 1

20,000 hours or

6 years

Fuel gas hose (regulator side) 1

Fuel gas hose clamp 4

Engine mount (8 TON only) 2

Loading...

Loading...