224

TROUBLESHOOTING

41) Inspect Indoor Fan Motor

Check the motor coil resistance and output voltage at the indoor fan motor connector.

42) Inspect for Blockage in the Indoor Electronic Expansion Valve

Make judgment by checking if the temperature difference of the pipes at each end of the electronic expansion

valve is normal.

43) Check Environmental Conditions (Low Intake Air Temperature)

Check if the intake air temperature of the outdoor heat exchanger is abnormally low due to a short circuit or influ-

ence of other equipment.

1. Select "Outside air temperature (code No. 4d)" in the monitor mode of the board maintenance functions to check

intake air temperature.

44) Inspect Strainer

45) Inspection Check Valve (Refrigerant Pressure Drop)

46) Inspect Refrigerant Low Pressure Sensor

1. Check for contact failure of connectors on the main PCB

1) Turn ON the electric leakage breaker.

2) Select "Refrigerant low pressure 1 (code No. 40)" in the monitor mode of the board maintenance functions.

3) Disconnect and connect the refrigerant low pressure sensor connector of CN4 on the main PCB, and check if

the pressure is displayed again.

4) If there is contact failure, repair it.

Temperature limit for operation (outdoor heat exchanger intake air temperature) 14 ℉ (-10 ℃ )

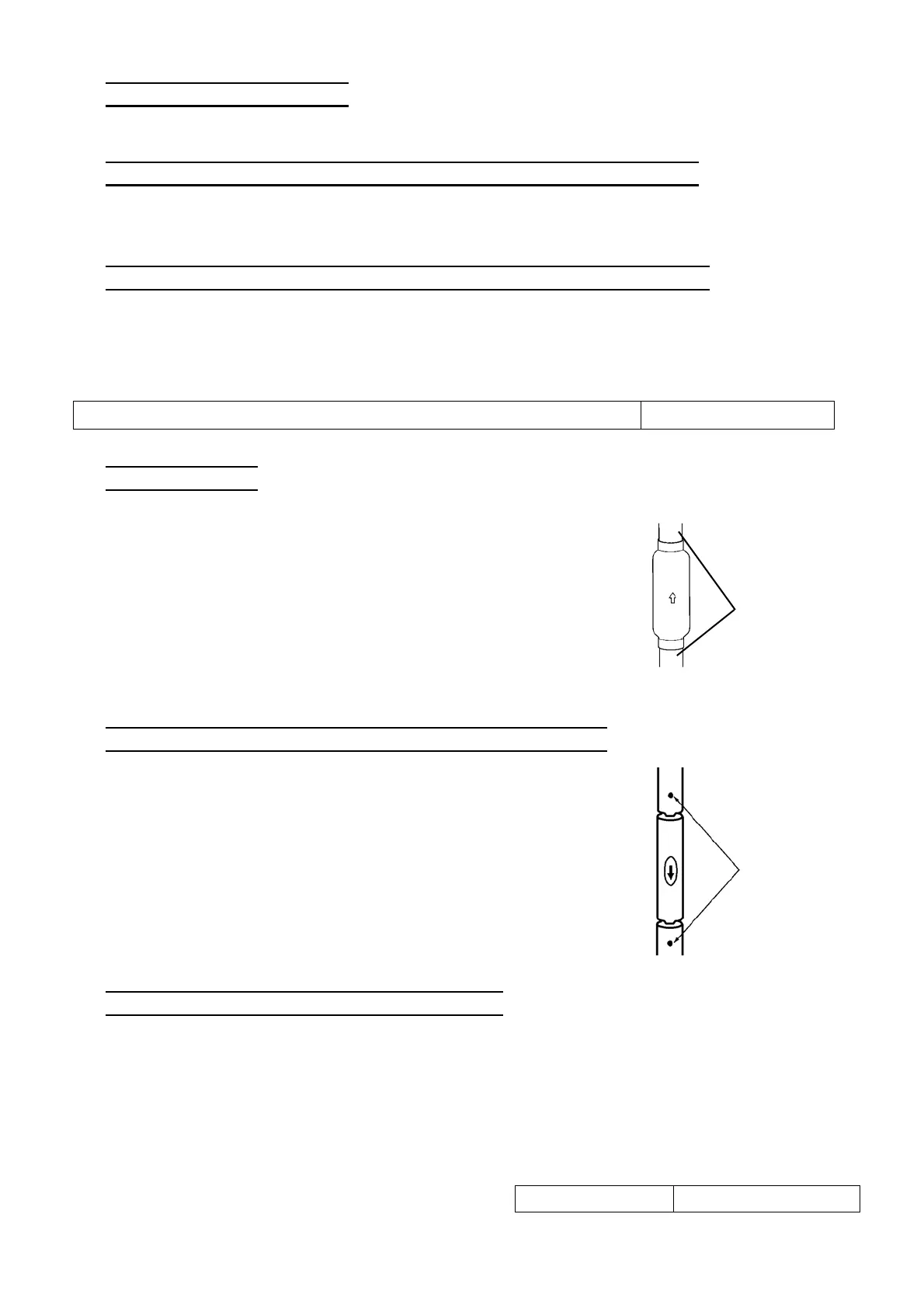

If the strainer just before the electronic expansion valve is fully or

partially blocked, the refrigerant pressure becomes low.

1. Measure the temperature of the pipes at each end of the strainer,

and check for extreme temperature difference (9℉(5℃) or more).

2. If the temperature difference between these positions is large,

the strainer is blocked. Replace the strainer.

NOTE) When replacing the refrigerant system parts, Refer to

P221, [Technical Data When Replacing the Refriger-

ant System Parts].

Strainer

Temperature

difference

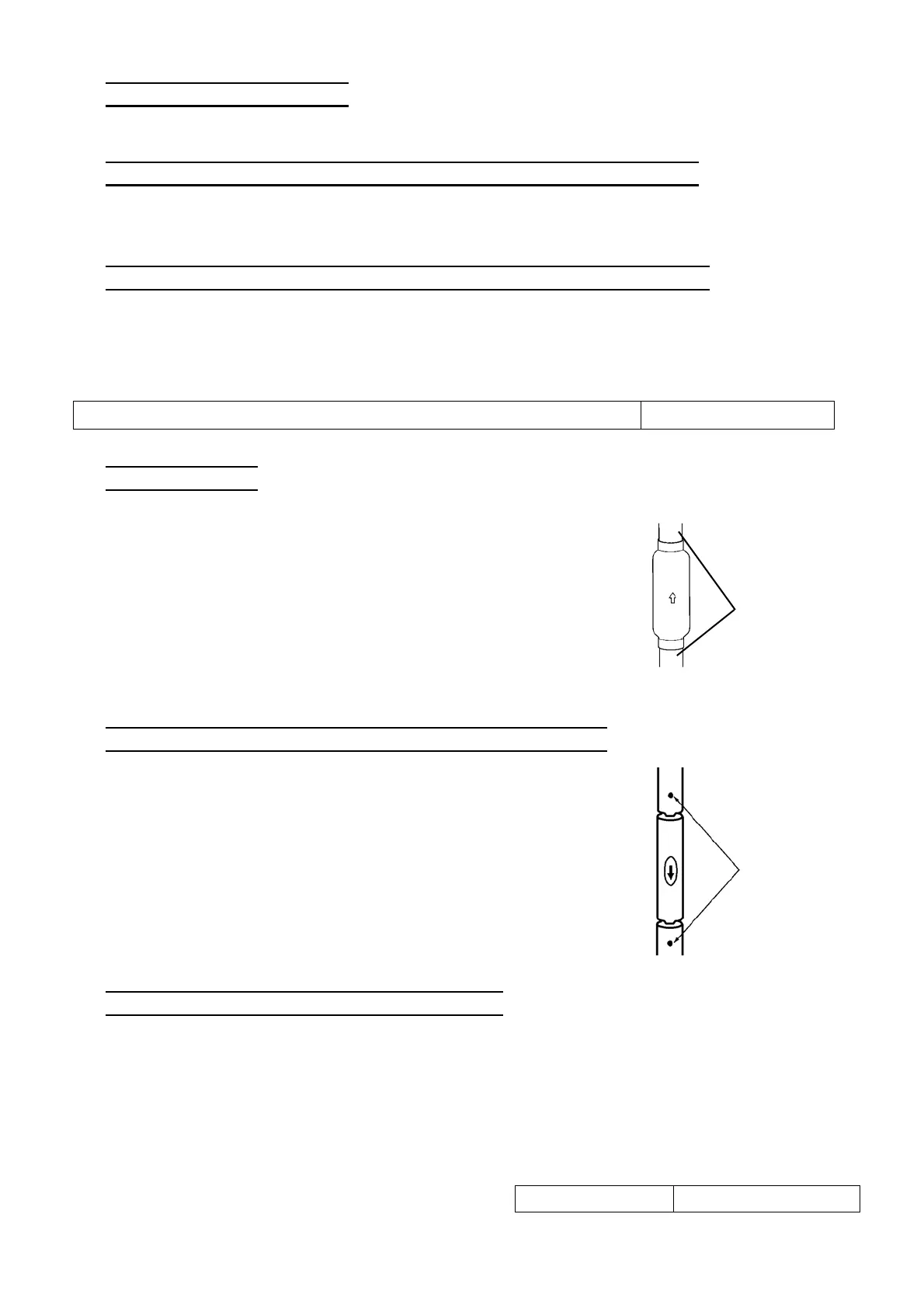

If the check valve is blocked, the refrigerant pressure drops.

1. Measure the temperature of the pipes at each end of the check

valve, and check for extreme temperature difference (9℉(5℃) or

more).

2. If the temperature difference between these positions is large,

the check valve is blocked. Replace the check valve.

NOTE) When replacing the refrigerant system parts, Refer to

P221, [Technical Data When Replacing the Refriger-

ant System Parts].

Check valve

Temperature

difference

2. Check power supply voltage of the refrigerant low

pressure sensor

Check power supply voltage of the refrigerant low

pressure sensor at CN4[34]-[12] on the main PCB.

Standard voltage Within 5 ± 0.25 V DC

Loading...

Loading...